Mikel Maiza

Integrated Water Resource Management in the Segura Hydrographic Basin: An Artificial Intelligence Approach

Nov 11, 2024

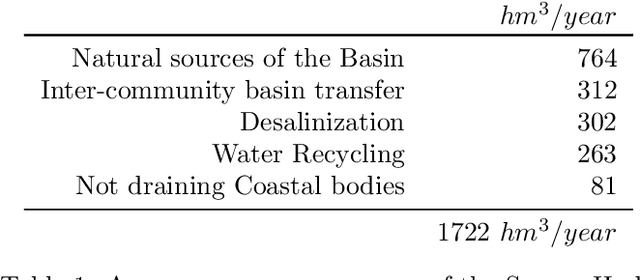

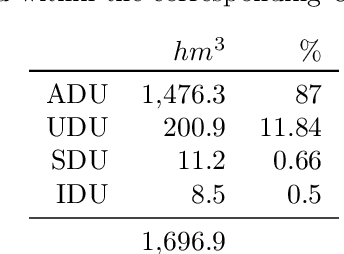

Abstract:Managing resources effectively in uncertain demand, variable availability, and complex governance policies is a significant challenge. This paper presents a paradigmatic framework for addressing these issues in water management scenarios by integrating advanced physical modelling, remote sensing techniques, and Artificial Intelligence algorithms. The proposed approach accurately predicts water availability, estimates demand, and optimizes resource allocation on both short- and long-term basis, combining a comprehensive hydrological model, agronomic crop models for precise demand estimation, and Mixed-Integer Linear Programming for efficient resource distribution. In the study case of the Segura Hydrographic Basin, the approach successfully allocated approximately 642 million cubic meters ($hm^3$) of water over six months, minimizing the deficit to 9.7% of the total estimated demand. The methodology demonstrated significant environmental benefits, reducing CO2 emissions while optimizing resource distribution. This robust solution supports informed decision-making processes, ensuring sustainable water management across diverse contexts. The generalizability of this approach allows its adaptation to other basins, contributing to improved governance and policy implementation on a broader scale. Ultimately, the methodology has been validated and integrated into the operational water management practices in the Segura Hydrographic Basin in Spain.

* 15 pages, 14 figures, 8 tables

A novel method for error analysis in radiation thermometry with application to industrial furnaces

Jan 10, 2022

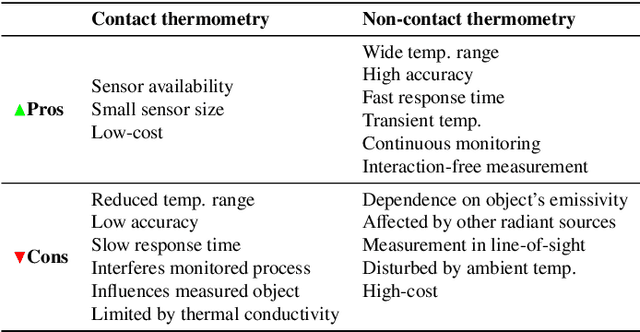

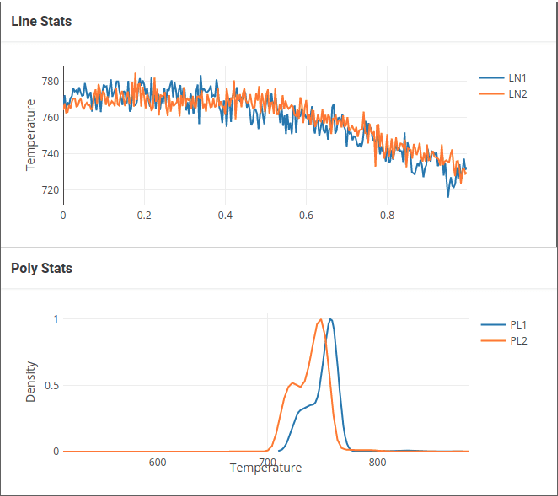

Abstract:Accurate temperature measurements are essential for the proper monitoring and control of industrial furnaces. However, measurement uncertainty is a risk for such a critical parameter. Certain instrumental and environmental errors must be considered when using spectral-band radiation thermometry techniques, such as the uncertainty in the emissivity of the target surface, reflected radiation from surrounding objects, or atmospheric absorption and emission, to name a few. Undesired contributions to measured radiation can be isolated using measurement models, also known as error-correction models. This paper presents a methodology for budgeting significant sources of error and uncertainty during temperature measurements in a petrochemical furnace scenario. A continuous monitoring system is also presented, aided by a deep-learning-based measurement correction model, to allow domain experts to analyze the furnace's operation in real-time. To validate the proposed system's functionality, a real-world application case in a petrochemical plant is presented. The proposed solution demonstrates the viability of precise industrial furnace monitoring, thereby increasing operational security and improving the efficiency of such energy-intensive systems.

Add to Chrome

Add to Chrome Add to Firefox

Add to Firefox Add to Edge

Add to Edge