Shubhan P. Patni

Interactive Learning of Physical Object Properties Through Robot Manipulation and Database of Object Measurements

Apr 10, 2024

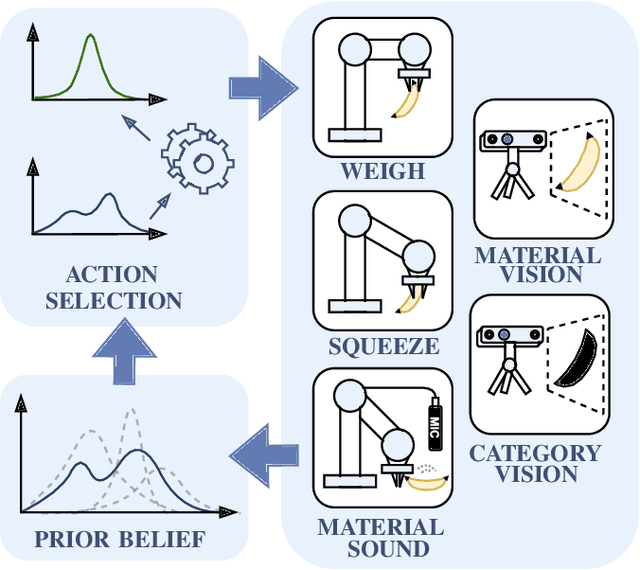

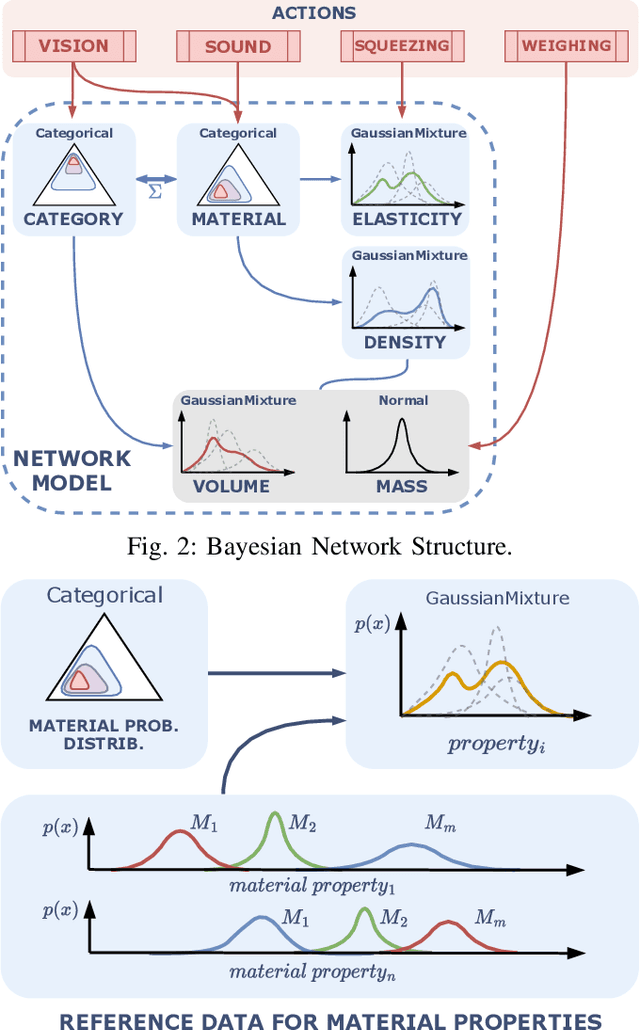

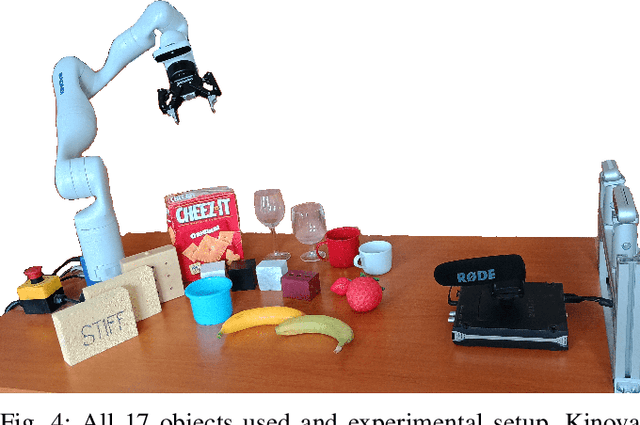

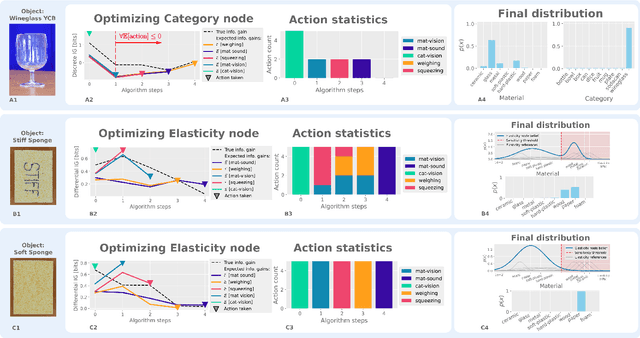

Abstract:This work presents a framework for automatically extracting physical object properties, such as material composition, mass, volume, and stiffness, through robot manipulation and a database of object measurements. The framework involves exploratory action selection to maximize learning about objects on a table. A Bayesian network models conditional dependencies between object properties, incorporating prior probability distributions and uncertainty associated with measurement actions. The algorithm selects optimal exploratory actions based on expected information gain and updates object properties through Bayesian inference. Experimental evaluation demonstrates effective action selection compared to a baseline and correct termination of the experiments if there is nothing more to be learned. The algorithm proved to behave intelligently when presented with trick objects with material properties in conflict with their appearance. The robot pipeline integrates with a logging module and an online database of objects, containing over 24,000 measurements of 63 objects with different grippers. All code and data are publicly available, facilitating automatic digitization of objects and their physical properties through exploratory manipulations.

Evaluating online elasticity estimation of soft objects using standard robot grippers

Jan 16, 2024Abstract:Standard robot grippers are not designed for elasticity estimation. In this work, a professional biaxial compression device was used as a control setup to study the accuracy with which material properties can be estimated by two standard parallel jaw grippers and a force/torque sensor mounted at the robot wrist. Using three sets of deformable objects, different parameters were varied to observe their effect on measuring material characteristics: (1) repeated compression cycles, (2) compression speed, and (3) the surface area of the gripper jaws. Gripper effort versus position curves were obtained and transformed into stress/strain curves. The modulus of elasticity was estimated at different strain points. Viscoelasticity was assessed using the energy absorbed in a compression/decompression cycle, the Kelvin-Voigt, and Hunt-Crossley models. Our results can be summarized as follows: (1) better results were obtained with slower compression speeds, while additional compression cycles or surface area did not improve estimation; (2) the robot grippers, even after calibration, were found to have a limited capability of delivering accurate estimates of absolute values of Young's modulus and viscoelasticity; (3) relative ordering of material characteristics was largely consistent across different grippers; (4) despite the nonlinear characteristics of deformable objects, fitting linear stress/strain approximations led to more stable results than local estimates of Young's modulus; (5) to assess viscoelasticity, the Hunt-Crossley model worked best. Finally, we show that a two-dimensional space representing elasticity and viscoelasticity estimates is advantageous for the discrimination of deformable objects. A single-grasp, online, classification and sorting of such objects is thus possible. An additional contribution is the dataset and data processing codes that we make publicly available.

Add to Chrome

Add to Chrome Add to Firefox

Add to Firefox Add to Edge

Add to Edge