Ralph Lange

Robert Bosch GmbH, Stuttgart, Germany

An Industrial Perspective on Multi-Agent Decision Making for Interoperable Robot Navigation following the VDA5050 Standard

Nov 24, 2023

Abstract:This paper provides a perspective on the literature and current challenges in Multi-Agent Systems for interoperable robot navigation in industry. The focus is on the multi-agent decision stack for Autonomous Mobile Robots operating in mixed environments with humans, manually driven vehicles, and legacy Automated Guided Vehicles. We provide typical characteristics of such Multi-Agent Systems observed today and how these are expected to change on the short term due to the new standard VDA5050 and the interoperability framework OpenRMF. We present recent changes in fleet management standards and the role of open middleware frameworks like ROS2 reaching industrial-grade quality. Approaches to increase the robustness and performance of multi-robot navigation systems for transportation are discussed, and research opportunities are derived.

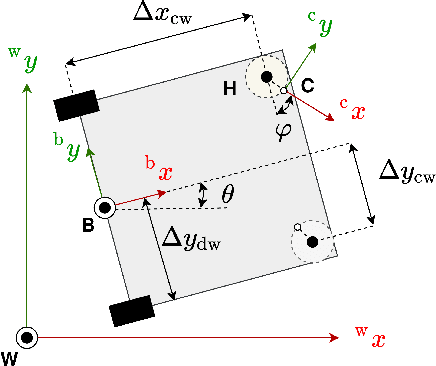

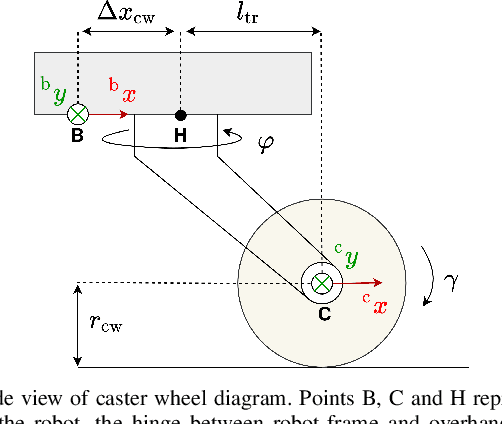

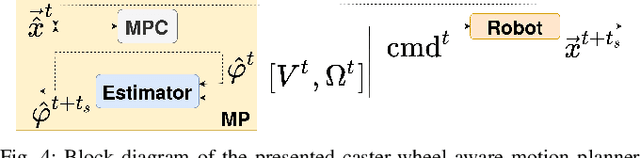

A caster-wheel-aware MPC-based motion planner for mobile robotics

Oct 11, 2021

Abstract:Differential drive mobile robots often use one or more caster wheels for balance. Caster wheels are appreciated for their ability to turn in any direction almost on the spot, allowing the robot to do the same and thereby greatly simplifying the motion planning and control. However, in aligning the caster wheels to the intended direction of motion they produce a so-called bore torque. As a result, additional motor torque is required to move the robot, which may in some cases exceed the motor capacity or compromise the motion planner's accuracy. Instead of taking a decoupled approach, where the navigation and disturbance rejection algorithms are separated, we propose to embed the caster wheel awareness into the motion planner. To do so, we present a caster-wheel-aware term that is compatible with MPC-based control methods, leveraging the existence of caster wheels in the motion planning stage. As a proof of concept, this term is combined with a a model-predictive trajectory tracking controller. Since this method requires knowledge of the caster wheel angle and rolling speed, an observer that estimates these states is also presented. The efficacy of the approach is shown in experiments on an intralogistics robot and compared against a decoupled bore-torque reduction approach and a caster-wheel agnostic controller. Moreover, the experiments show that the presented caster wheel estimator performs sufficiently well and therefore avoids the need for additional sensors.

Budget-based real-time Executor for Micro-ROS

May 18, 2021

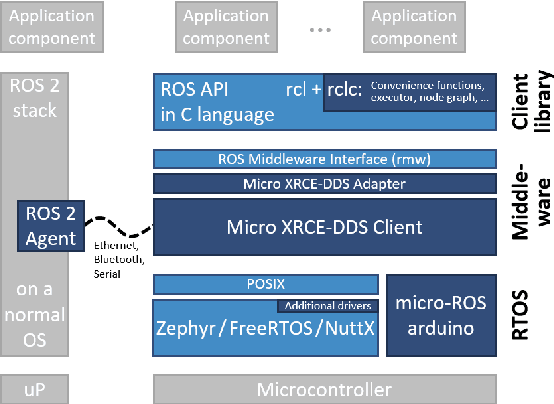

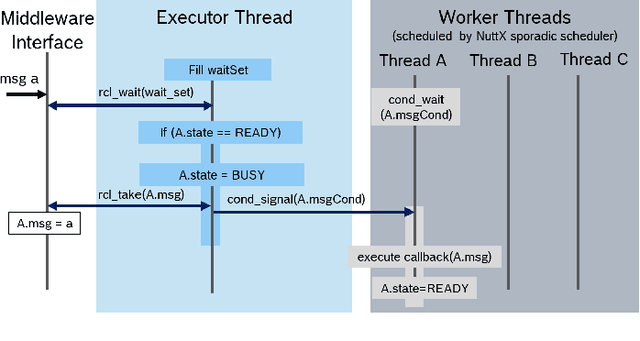

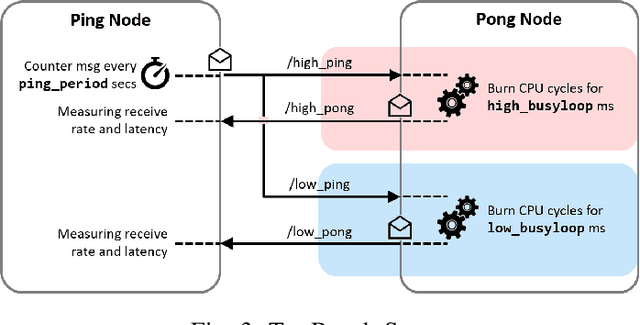

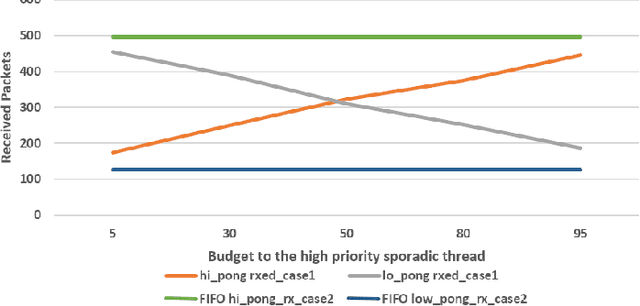

Abstract:The Robot Operating System (ROS) is a popular robotics middleware framework. In the last years, it underwent a redesign and reimplementation under the name ROS~2. It now features QoS-configurable communication and a flexible layered architecture. Micro-ROS is a variant developed specifically for resource-constrained microcontrollers (MCU). Such MCUs are commonly used in robotics for sensors and actuators, for time-critical control functions, and for safety. While the execution management of ROS 2 has been addressed by an Executor concept, its lack of real-time capabilities make it unsuitable for industrial use. Neither defining an execution order nor the assignment of scheduling parameters to tasks is possible, despite the fact that advanced real-time scheduling algorithms are well-known and available in modern RTOS's. For example, the NuttX RTOS supports a variant of the reservation-based scheduling which is very attractive for industrial applications: It allows to assign execution time budgets to software components so that a system integrator can thereby guarantee the real-time requirements of the entire system. This paper presents for the first time a ROS~2 Executor design which enables the real-time scheduling capabilities of the operating system. In particular, we successfully demonstrate the budget-based scheduling of the NuttX RTOS with a micro-ROS application on an STM32 microcontroller.

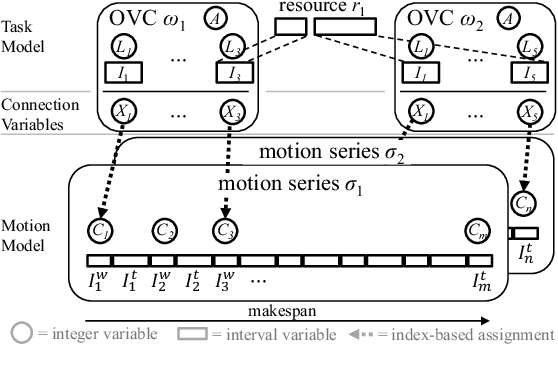

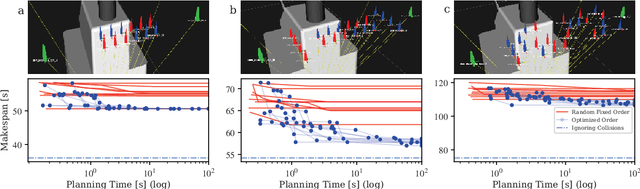

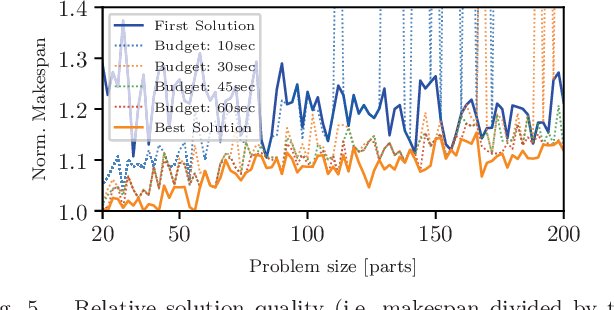

A Constraint Programming Approach to Simultaneous Task Allocation and Motion Scheduling for Industrial Dual-Arm Manipulation Tasks

Jan 23, 2019

Abstract:Modern lightweight dual-arm robots bring the physical capabilities to quickly take over tasks at typical industrial workplaces designed for workers. In times of mass-customization, low setup times including the instructing/specifying of new tasks are crucial to stay competitive. We propose a constraint programming approach to simultaneous task allocation and motion scheduling for such industrial manipulation and assembly tasks. The proposed approach covers dual-arm and even multi-arm robots as well as connected machines. The key concept are Ordered Visiting Constraints, a descriptive and extensible model to specify such tasks with their spatiotemporal requirements and task-specific combinatorial or ordering constraints. Our solver integrates such task models and robot motion models into constraint optimization problems and solves them efficiently using various heuristics to produce makespan-optimized robot programs. The proposed task model is robot independent and thus can easily be deployed to other robotic platforms. Flexibility and portability of our proposed model is validated through several experiments on different simulated robot platforms. We benchmarked our search strategy against a general-purpose heuristic. For large manipulation tasks with 200 objects, our solver implemented using Google's Operations Research tools and ROS requires less than a minute to compute usable plans.

Add to Chrome

Add to Chrome Add to Firefox

Add to Firefox Add to Edge

Add to Edge