Ognjen Savkovic

Scaling Data Science Solutions with Semantics and Machine Learning: Bosch Case

Aug 02, 2023

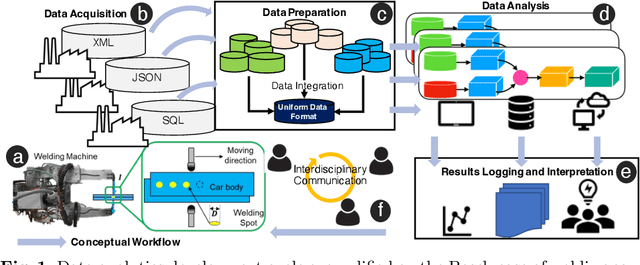

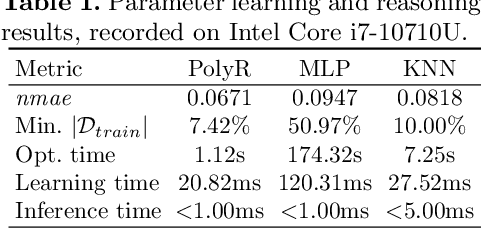

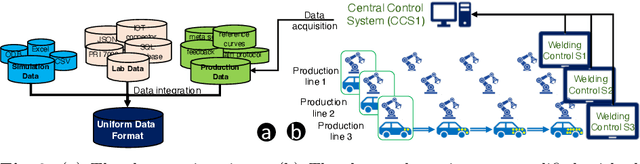

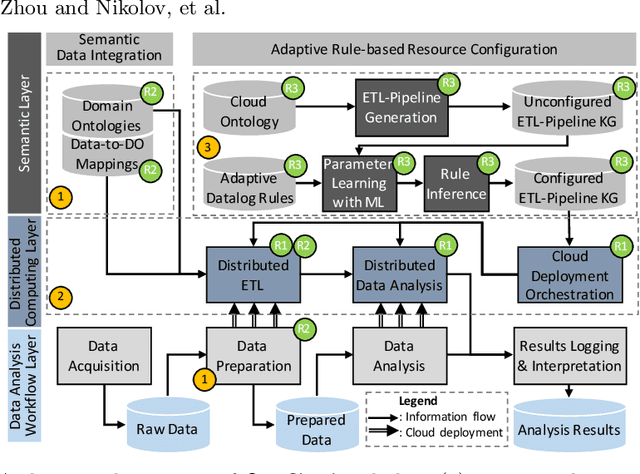

Abstract:Industry 4.0 and Internet of Things (IoT) technologies unlock unprecedented amount of data from factory production, posing big data challenges in volume and variety. In that context, distributed computing solutions such as cloud systems are leveraged to parallelise the data processing and reduce computation time. As the cloud systems become increasingly popular, there is increased demand that more users that were originally not cloud experts (such as data scientists, domain experts) deploy their solutions on the cloud systems. However, it is non-trivial to address both the high demand for cloud system users and the excessive time required to train them. To this end, we propose SemCloud, a semantics-enhanced cloud system, that couples cloud system with semantic technologies and machine learning. SemCloud relies on domain ontologies and mappings for data integration, and parallelises the semantic data integration and data analysis on distributed computing nodes. Furthermore, SemCloud adopts adaptive Datalog rules and machine learning for automated resource configuration, allowing non-cloud experts to use the cloud system. The system has been evaluated in industrial use case with millions of data, thousands of repeated runs, and domain users, showing promising results.

Literal-Aware Knowledge Graph Embedding for Welding Quality Monitoring: A Bosch Case

Aug 02, 2023

Abstract:Recently there has been a series of studies in knowledge graph embedding (KGE), which attempts to learn the embeddings of the entities and relations as numerical vectors and mathematical mappings via machine learning (ML). However, there has been limited research that applies KGE for industrial problems in manufacturing. This paper investigates whether and to what extent KGE can be used for an important problem: quality monitoring for welding in manufacturing industry, which is an impactful process accounting for production of millions of cars annually. The work is in line with Bosch research of data-driven solutions that intends to replace the traditional way of destroying cars, which is extremely costly and produces waste. The paper tackles two very challenging questions simultaneously: how large the welding spot diameter is; and to which car body the welded spot belongs to. The problem setting is difficult for traditional ML because there exist a high number of car bodies that should be assigned as class labels. We formulate the problem as link prediction, and experimented popular KGE methods on real industry data, with consideration of literals. Our results reveal both limitations and promising aspects of adapted KGE methods.

Add to Chrome

Add to Chrome Add to Firefox

Add to Firefox Add to Edge

Add to Edge