Mathilde Hotvedt

Passive learning to address nonstationarity in virtual flow metering applications

Feb 07, 2022

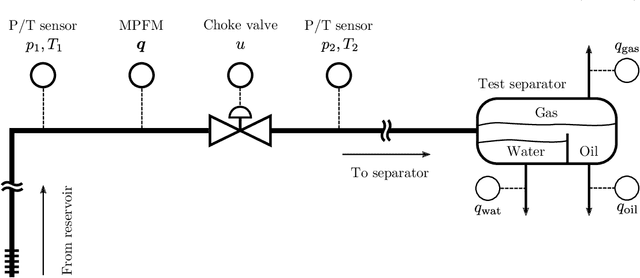

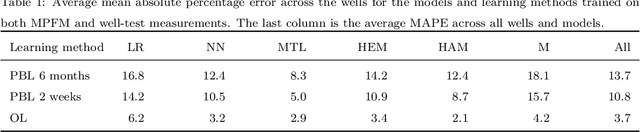

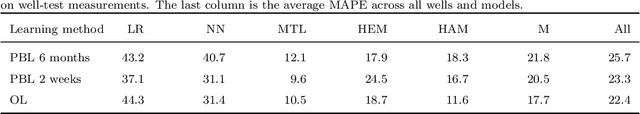

Abstract:Steady-state process models are common in virtual flow meter applications due to low computational complexity, and low model development and maintenance cost. Nevertheless, the prediction performance of steady-state models typically degrades with time due to the inherent nonstationarity of the underlying process being modeled. Few studies have investigated how learning methods can be applied to sustain the prediction accuracy of steady-state virtual flow meters. This paper explores passive learning, where the model is frequently calibrated to new data, as a way to address nonstationarity and improve long-term performance. An advantage with passive learning is that it is compatible with models used in the industry. Two passive learning methods, periodic batch learning and online learning, are applied with varying calibration frequency to train virtual flow meters. Six different model types, ranging from data-driven to first-principles, are trained on historical production data from 10 petroleum wells. The results are two-fold: first, in the presence of frequently arriving measurements, frequent model updating sustains an excellent prediction performance over time; second, in the presence of intermittent and infrequently arriving measurements, frequent updating in addition to the utilization of expert knowledge is essential to increase the performance accuracy. The investigation may be of interest to experts developing soft-sensors for nonstationary processes, such as virtual flow meters.

On gray-box modeling for virtual flow metering

Mar 23, 2021

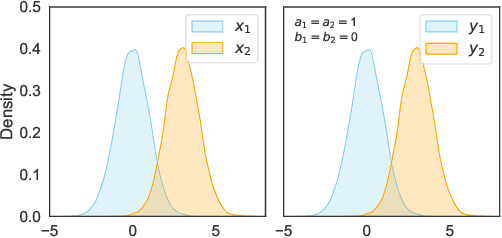

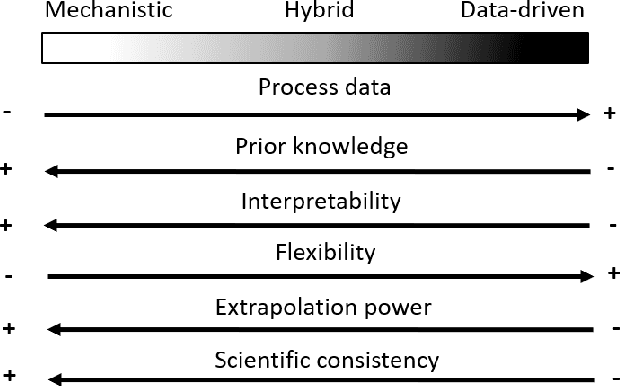

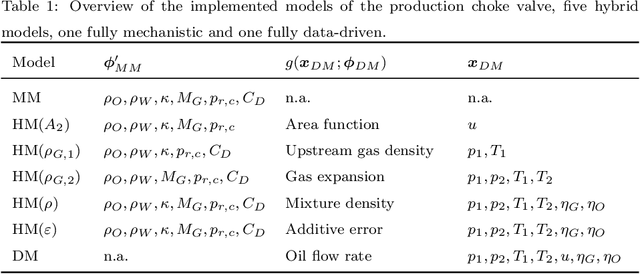

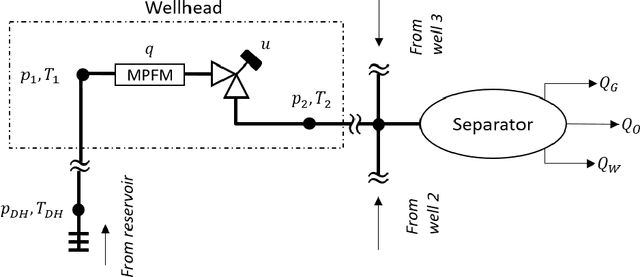

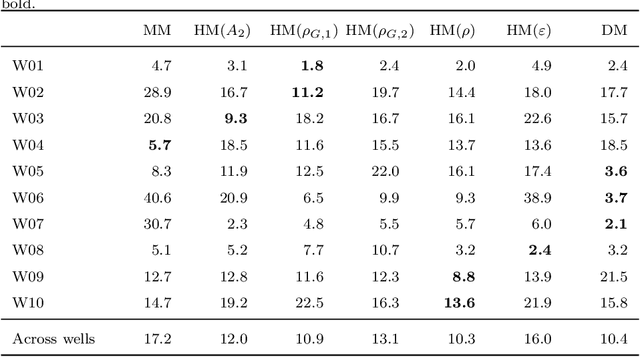

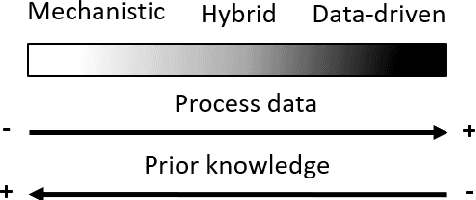

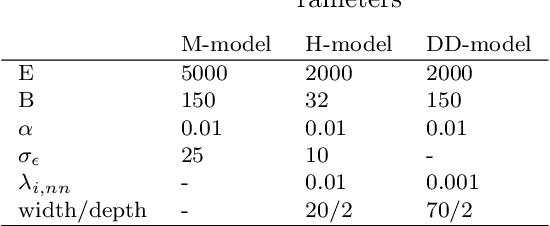

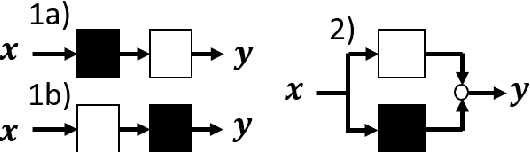

Abstract:A virtual flow meter (VFM) enables continuous prediction of flow rates in petroleum production systems. The predicted flow rates may aid the daily control and optimization of a petroleum asset. Gray-box modeling is an approach that combines mechanistic and data-driven modeling. The objective is to create a VFM with higher accuracy than a mechanistic VFM, and with a higher scientific consistency than a data-driven VFM. This article investigates five different gray-box model types in an industrial case study on 10 petroleum wells. The study casts light upon the nontrivial task of balancing learning from physics and data. The results indicate that the inclusion of data-driven elements in a mechanistic model improves the predictive performance of the model while insignificantly influencing the scientific consistency. However, the results are influenced by the available data. The findings encourage future research into online learning and the utilization of methods that incorporate data from several wells.

Bayesian Neural Networks for Virtual Flow Metering: An Empirical Study

Feb 02, 2021

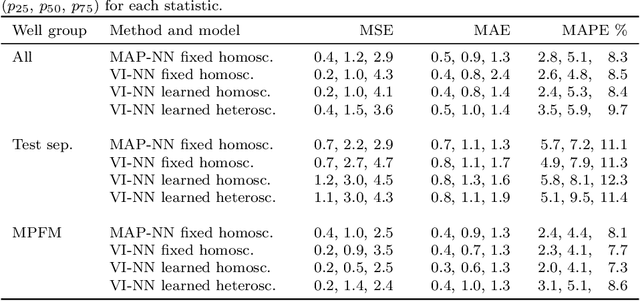

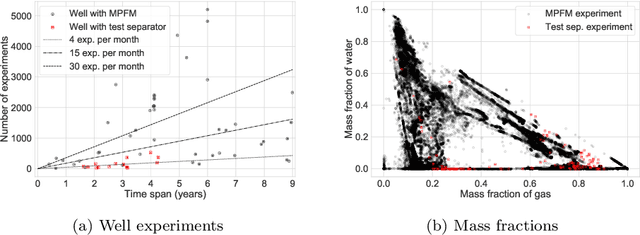

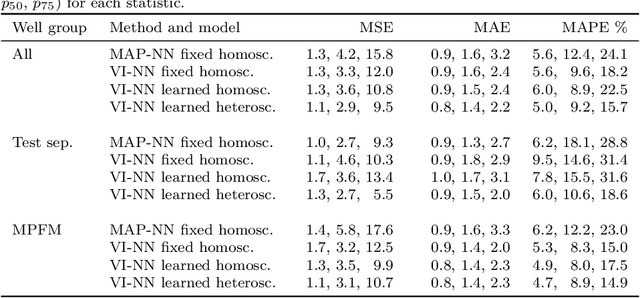

Abstract:Recent works have presented promising results from the application of machine learning (ML) to the modeling of flow rates in oil and gas wells. The encouraging results combined with advantageous properties of ML models, such as computationally cheap evaluation and ease of calibration to new data, have sparked optimism for the development of data-driven virtual flow meters (VFMs). We contribute to this development by presenting a probabilistic VFM based on a Bayesian neural network. We consider homoscedastic and heteroscedastic measurement noise, and show how to train the models using maximum a posteriori estimation and variational inference. We study the methods by modeling on a large and heterogeneous dataset, consisting of 60 wells across five different oil and gas assets. The predictive performance is analyzed on historical and future test data, where we achieve an average error of 5-6% and 9-13% for the 50% best performing models, respectively. Variational inference appears to provide more robust predictions than the reference approach on future data. The difference in prediction performance and uncertainty on historical and future data is explored in detail, and the findings motivate the development of alternative strategies for data-driven VFM.

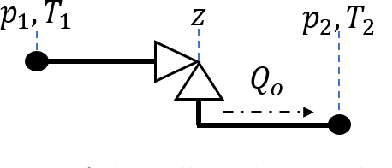

Developing a Hybrid Data-Driven, Mechanistic Virtual Flow Meter -- a Case Study

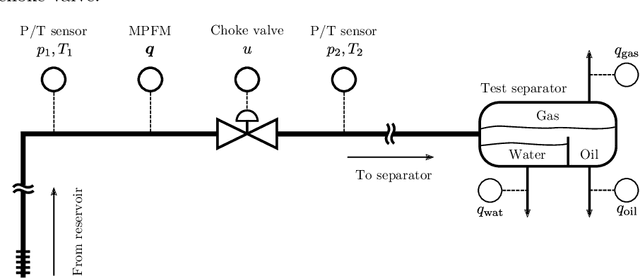

Feb 07, 2020

Abstract:Virtual flow meters, mathematical models predicting production flow rates in petroleum assets, are useful aids in production monitoring and optimization. Mechanistic models based on first-principles are most common, however, data-driven models exploiting patterns in measurements are gaining popularity. This research investigates a hybrid modeling approach, utilizing techniques from both the aforementioned areas of expertise, to model a well production choke. The choke is represented with a simplified set of first-principle equations and a neural network to estimate the valve flow coefficient. Historical production data from the petroleum platform Edvard Grieg is used for model validation. Additionally, a mechanistic and a data-driven model are constructed for comparison of performance. A practical framework for development of models with varying degree of hybridity and stochastic optimization of its parameters is established. Results of the hybrid model performance are promising albeit with considerable room for improvements.

Add to Chrome

Add to Chrome Add to Firefox

Add to Firefox Add to Edge

Add to Edge