Passive learning to address nonstationarity in virtual flow metering applications

Paper and Code

Feb 07, 2022

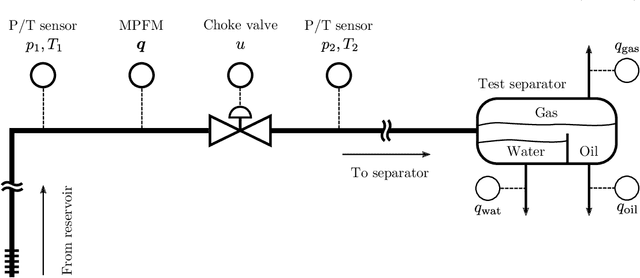

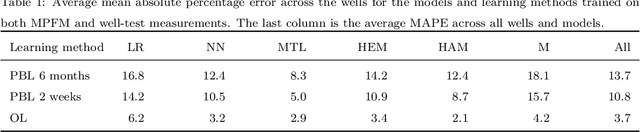

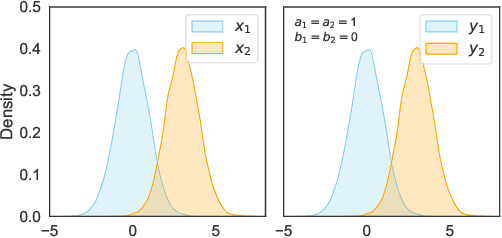

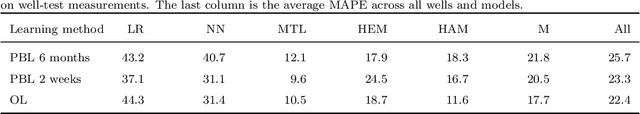

Steady-state process models are common in virtual flow meter applications due to low computational complexity, and low model development and maintenance cost. Nevertheless, the prediction performance of steady-state models typically degrades with time due to the inherent nonstationarity of the underlying process being modeled. Few studies have investigated how learning methods can be applied to sustain the prediction accuracy of steady-state virtual flow meters. This paper explores passive learning, where the model is frequently calibrated to new data, as a way to address nonstationarity and improve long-term performance. An advantage with passive learning is that it is compatible with models used in the industry. Two passive learning methods, periodic batch learning and online learning, are applied with varying calibration frequency to train virtual flow meters. Six different model types, ranging from data-driven to first-principles, are trained on historical production data from 10 petroleum wells. The results are two-fold: first, in the presence of frequently arriving measurements, frequent model updating sustains an excellent prediction performance over time; second, in the presence of intermittent and infrequently arriving measurements, frequent updating in addition to the utilization of expert knowledge is essential to increase the performance accuracy. The investigation may be of interest to experts developing soft-sensors for nonstationary processes, such as virtual flow meters.

Add to Chrome

Add to Chrome Add to Firefox

Add to Firefox Add to Edge

Add to Edge