On gray-box modeling for virtual flow metering

Paper and Code

Mar 23, 2021

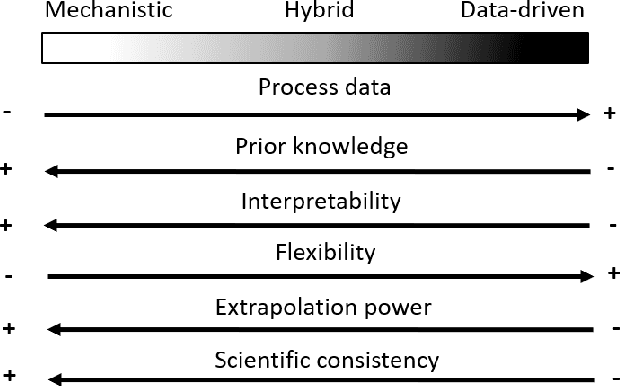

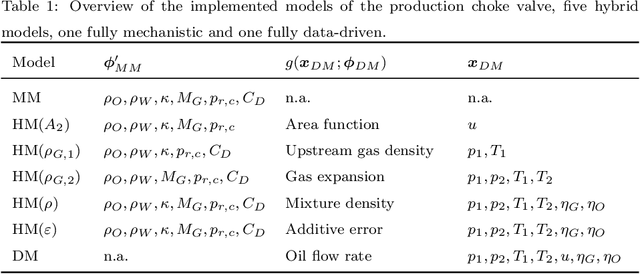

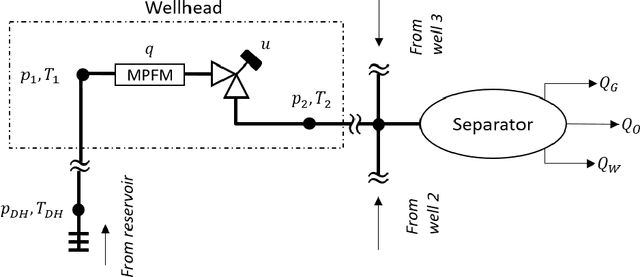

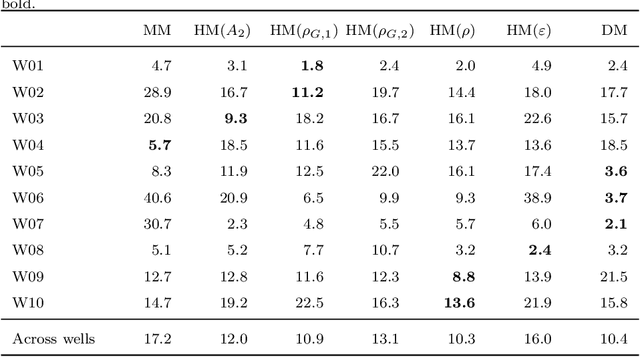

A virtual flow meter (VFM) enables continuous prediction of flow rates in petroleum production systems. The predicted flow rates may aid the daily control and optimization of a petroleum asset. Gray-box modeling is an approach that combines mechanistic and data-driven modeling. The objective is to create a VFM with higher accuracy than a mechanistic VFM, and with a higher scientific consistency than a data-driven VFM. This article investigates five different gray-box model types in an industrial case study on 10 petroleum wells. The study casts light upon the nontrivial task of balancing learning from physics and data. The results indicate that the inclusion of data-driven elements in a mechanistic model improves the predictive performance of the model while insignificantly influencing the scientific consistency. However, the results are influenced by the available data. The findings encourage future research into online learning and the utilization of methods that incorporate data from several wells.

Add to Chrome

Add to Chrome Add to Firefox

Add to Firefox Add to Edge

Add to Edge