Fulei Chu

MaintAGT:Sim2Real-Guided Multimodal Large Model for Intelligent Maintenance with Chain-of-Thought Reasoning

Nov 30, 2024

Abstract:In recent years, large language models have made significant advancements in the field of natural language processing, yet there are still inadequacies in specific domain knowledge and applications. This paper Proposes MaintAGT, a professional large model for intelligent operations and maintenance, aimed at addressing this issue. The system comprises three key components: a signal-to-text model, a pure text model, and a multimodal model. Firstly, the signal-to-text model was designed to convert raw signal data into textual descriptions, bridging the gap between signal data and text-based analysis. Secondly, the pure text model was fine-tuned using the GLM4 model with specialized knowledge to enhance its understanding of domain-specific texts. Finally, these two models were integrated to develop a comprehensive multimodal model that effectively processes and analyzes both signal and textual data.The dataset used for training and evaluation was sourced from academic papers, textbooks, international standards, and vibration analyst training materials, undergoing meticulous preprocessing to ensure high-quality data. As a result, the model has demonstrated outstanding performance across multiple intelligent operations and maintenance tasks, providing a low-cost, high-quality method for constructing large-scale monitoring signal-text description-fault pattern datasets. Experimental results indicate that the model holds significant advantages in condition monitoring, signal processing, and fault diagnosis.In the constructed general test set, MaintAGT achieved an accuracy of 70%, surpassing all existing general large language models and reaching the level of an ISO Level III human vibration analyst.This advancement signifies a crucial step forward from traditional maintenance practices toward intelligent and AI-driven maintenance solutions.

Classifier-Free Diffusion-Based Weakly-Supervised Approach for Health Indicator Derivation in Rotating Machines: Advancing Early Fault Detection and Condition Monitoring

Sep 03, 2024

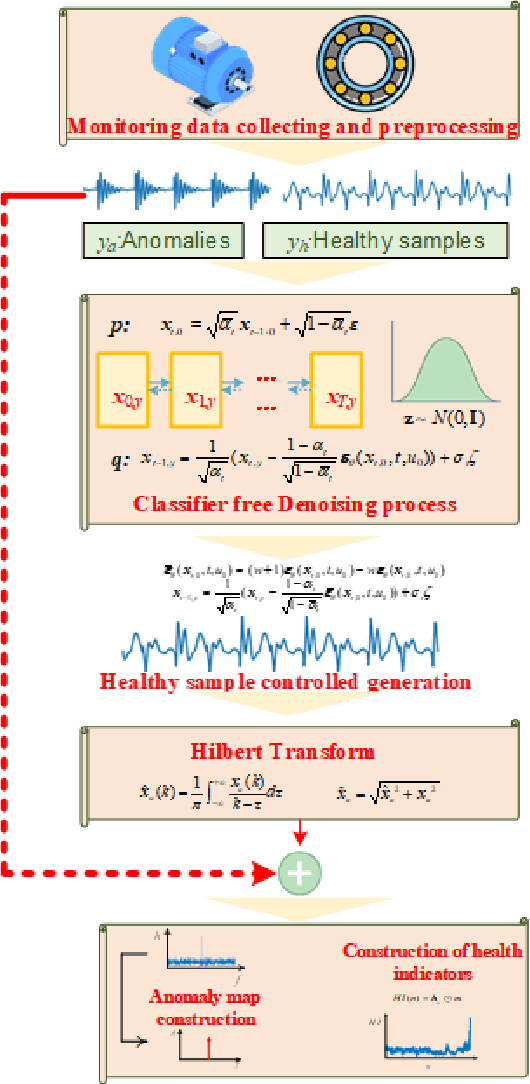

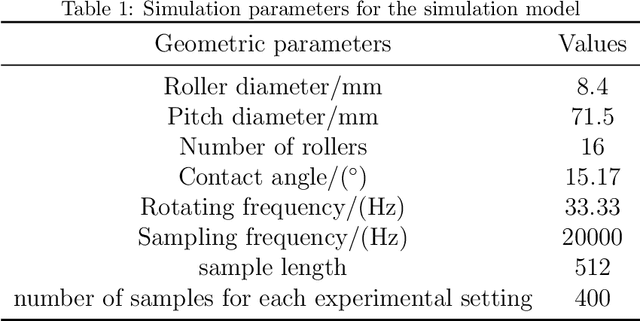

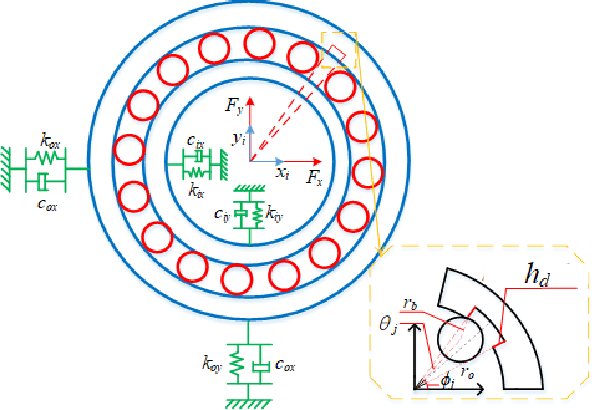

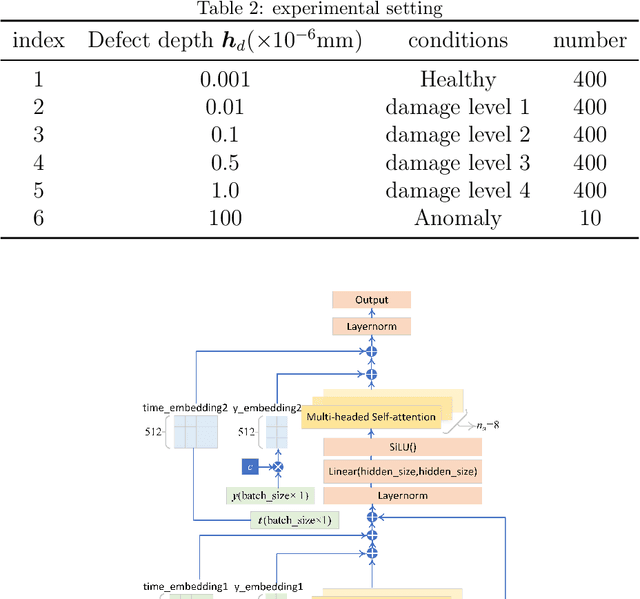

Abstract:Deriving health indicators of rotating machines is crucial for their maintenance. However, this process is challenging for the prevalent adopted intelligent methods since they may take the whole data distributions, not only introducing noise interference but also lacking the explainability. To address these issues, we propose a diffusion-based weakly-supervised approach for deriving health indicators of rotating machines, enabling early fault detection and continuous monitoring of condition evolution. This approach relies on a classifier-free diffusion model trained using healthy samples and a few anomalies. This model generates healthy samples. and by comparing the differences between the original samples and the generated ones in the envelope spectrum, we construct an anomaly map that clearly identifies faults. Health indicators are then derived, which can explain the fault types and mitigate noise interference. Comparative studies on two cases demonstrate that the proposed method offers superior health monitoring effectiveness and robustness compared to baseline models.

Add to Chrome

Add to Chrome Add to Firefox

Add to Firefox Add to Edge

Add to Edge