Elizabeth A. Holm

Microstructure Generation via Generative Adversarial Network for Heterogeneous, Topologically Complex 3D Materials

Jun 22, 2020

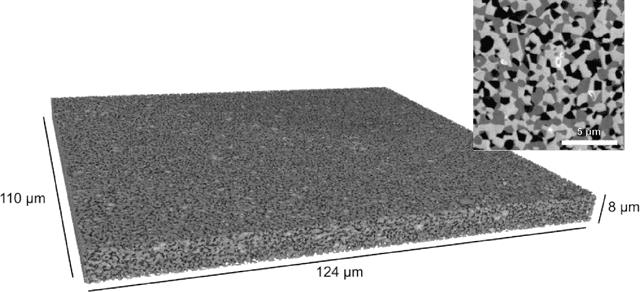

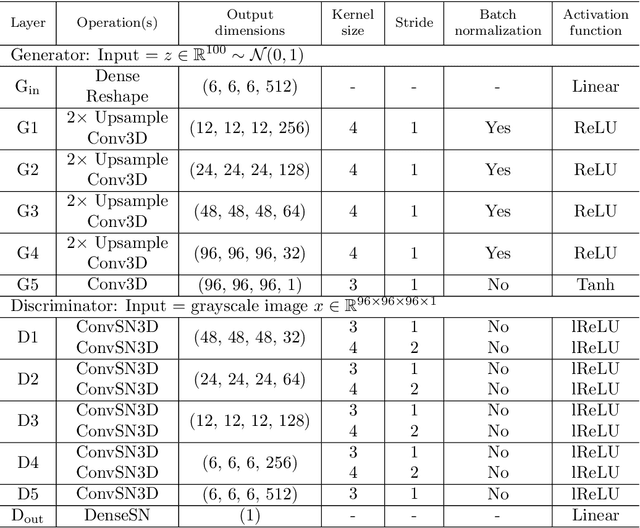

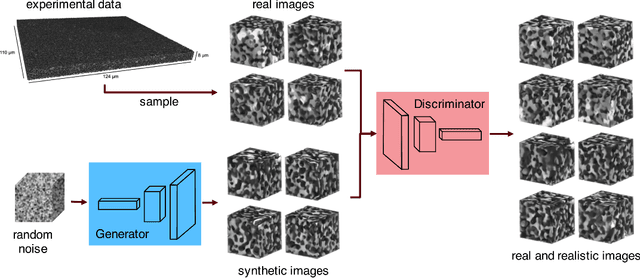

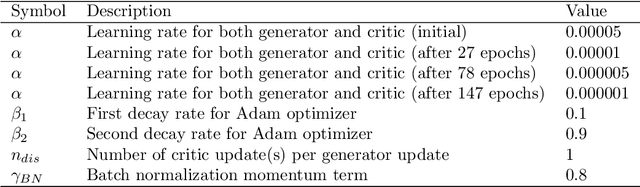

Abstract:Using a large-scale, experimentally captured 3D microstructure dataset, we implement the generative adversarial network (GAN) framework to learn and generate 3D microstructures of solid oxide fuel cell electrodes. The generated microstructures are visually, statistically, and topologically realistic, with distributions of microstructural parameters, including volume fraction, particle size, surface area, tortuosity, and triple phase boundary density, being highly similar to those of the original microstructure. These results are compared and contrasted with those from an established, grain-based generation algorithm (DREAM.3D). Importantly, simulations of electrochemical performance, using a locally resolved finite element model, demonstrate that the GAN generated microstructures closely match the performance distribution of the original, while DREAM.3D leads to significant differences. The ability of the generative machine learning model to recreate microstructures with high fidelity suggests that the essence of complex microstructures may be captured and represented in a compact and manipulatable form.

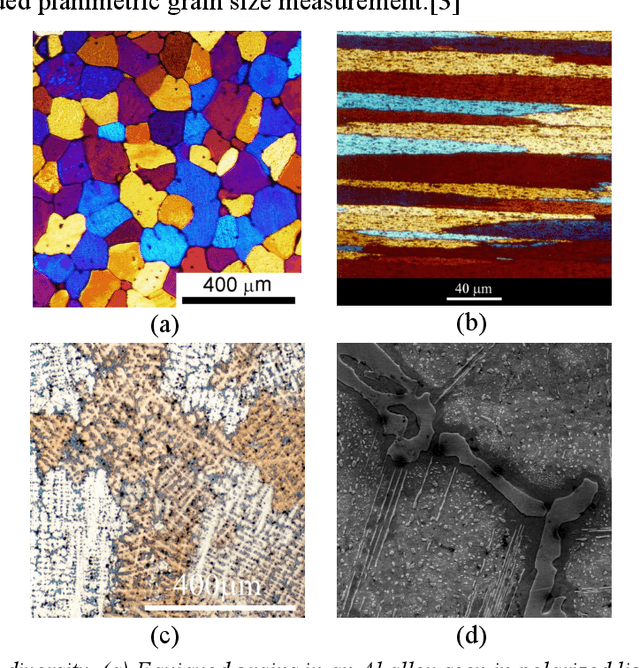

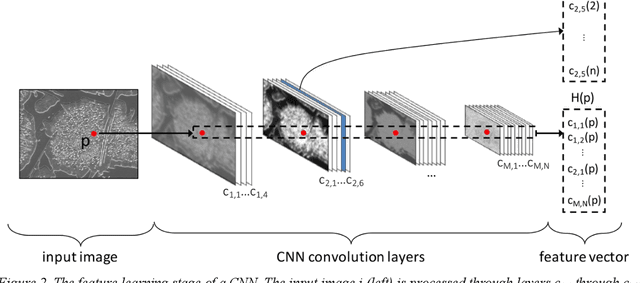

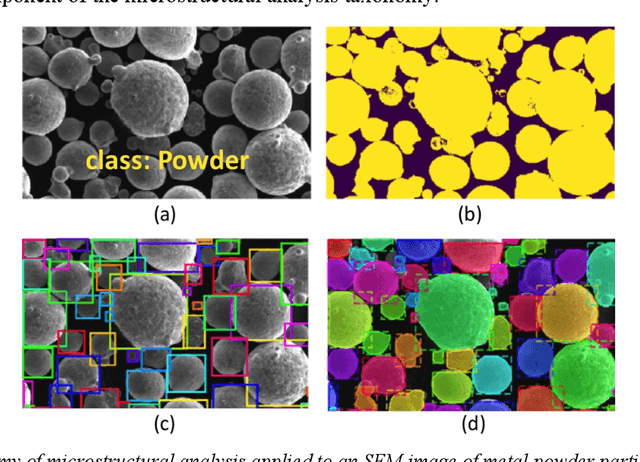

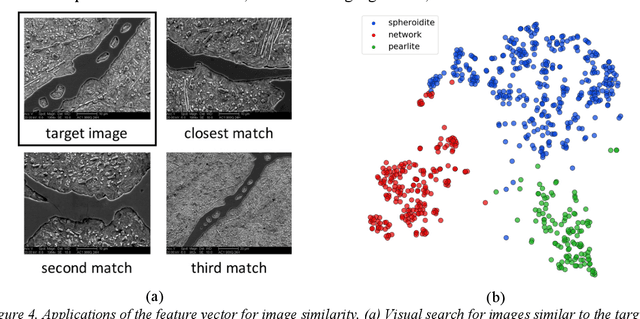

Overview: Computer vision and machine learning for microstructural characterization and analysis

May 28, 2020

Abstract:The characterization and analysis of microstructure is the foundation of microstructural science, connecting the materials structure to its composition, process history, and properties. Microstructural quantification traditionally involves a human deciding a priori what to measure and then devising a purpose-built method for doing so. However, recent advances in data science, including computer vision (CV) and machine learning (ML) offer new approaches to extracting information from microstructural images. This overview surveys CV approaches to numerically encode the visual information contained in a microstructural image, which then provides input to supervised or unsupervised ML algorithms that find associations and trends in the high-dimensional image representation. CV/ML systems for microstructural characterization and analysis span the taxonomy of image analysis tasks, including image classification, semantic segmentation, object detection, and instance segmentation. These tools enable new approaches to microstructural analysis, including the development of new, rich visual metrics and the discovery of processing-microstructure-property relationships.

High throughput quantitative metallography for complex microstructures using deep learning: A case study in ultrahigh carbon steel

May 04, 2018

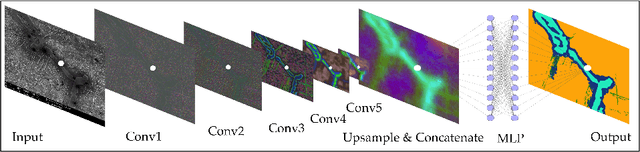

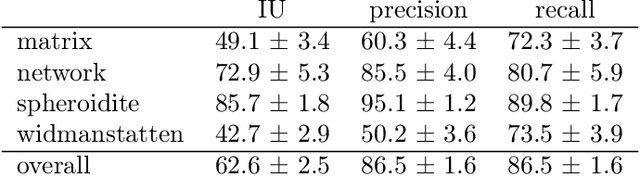

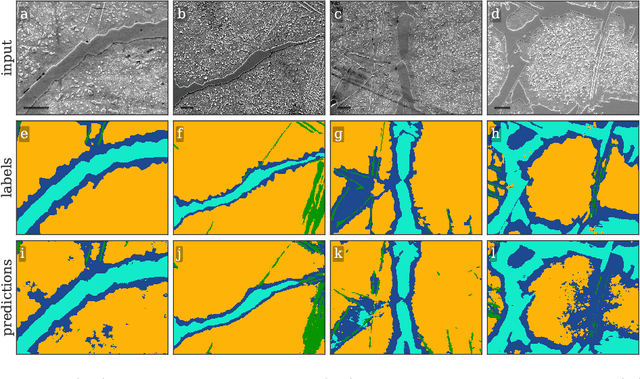

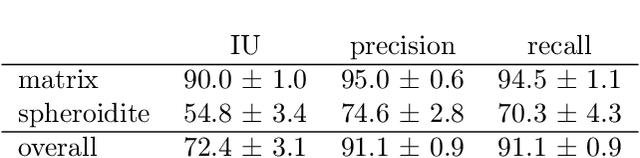

Abstract:We apply a deep convolutional neural network segmentation model to enable novel automated microstructure segmentation applications for complex microstructures typically evaluated manually and subjectively. We explore two microstructure segmentation tasks in an openly-available ultrahigh carbon steel microstructure dataset: segmenting cementite particles in the spheroidized matrix, and segmenting larger fields of view featuring grain boundary carbide, spheroidized particle matrix, particle-free grain boundary denuded zone, and Widmanst\"atten cementite. We also demonstrate how to combine these data-driven microstructure segmentation models to obtain empirical cementite particle size and denuded zone width distributions from more complex micrographs containing multiple microconstituents. The full annotated dataset is available on materialsdata.nist.gov (https://materialsdata.nist.gov/handle/11256/964).

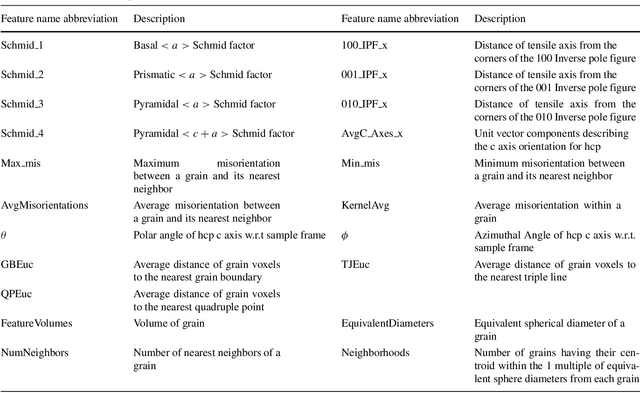

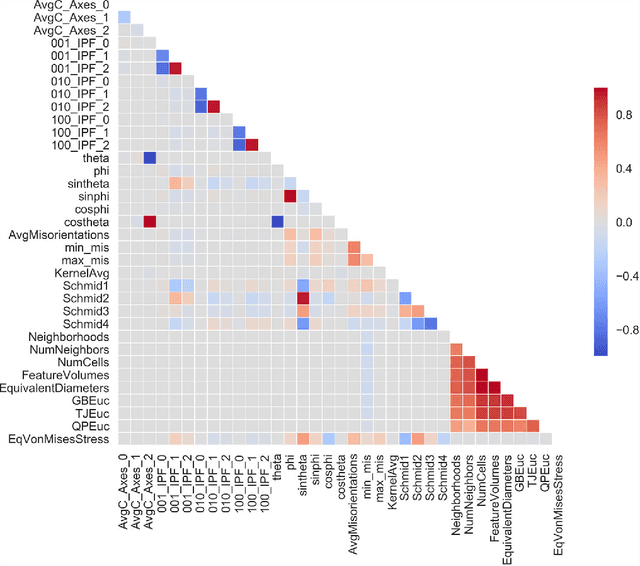

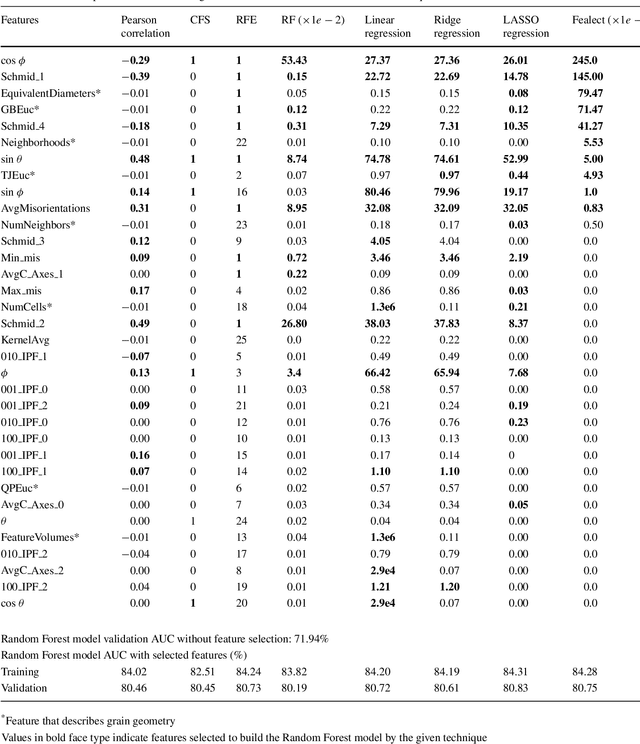

A comparative study of feature selection methods for stress hotspot classification in materials

Apr 19, 2018

Abstract:The first step in constructing a machine learning model is defining the features of the data set that can be used for optimal learning. In this work we discuss feature selection methods, which can be used to build better models, as well as achieve model interpretability. We applied these methods in the context of stress hotspot classification problem, to determine what microstructural characteristics can cause stress to build up in certain grains during uniaxial tensile deformation. The results show how some feature selection techniques are biased and demonstrate a preferred technique to get feature rankings for physical interpretations.

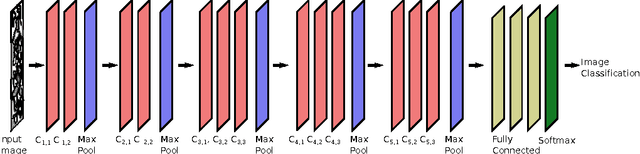

Building Data-driven Models with Microstructural Images: Generalization and Interpretability

Nov 01, 2017

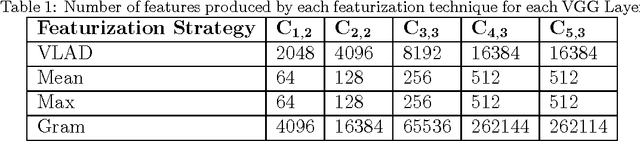

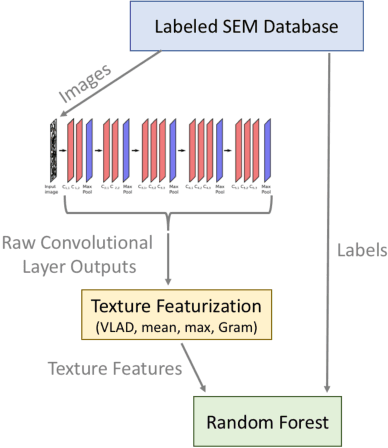

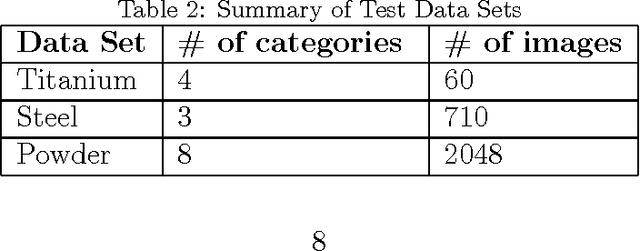

Abstract:As data-driven methods rise in popularity in materials science applications, a key question is how these machine learning models can be used to understand microstructure. Given the importance of process-structure-property relations throughout materials science, it seems logical that models that can leverage microstructural data would be more capable of predicting property information. While there have been some recent attempts to use convolutional neural networks to understand microstructural images, these early studies have focused only on which featurizations yield the highest machine learning model accuracy for a single data set. This paper explores the use of convolutional neural networks for classifying microstructure with a more holistic set of objectives in mind: generalization between data sets, number of features required, and interpretability.

Add to Chrome

Add to Chrome Add to Firefox

Add to Firefox Add to Edge

Add to Edge