Ryan Cohn

Carnegie Mellon University

Neural message passing for predicting abnormal grain growth in Monte Carlo simulations of microstructural evolution

Oct 18, 2021

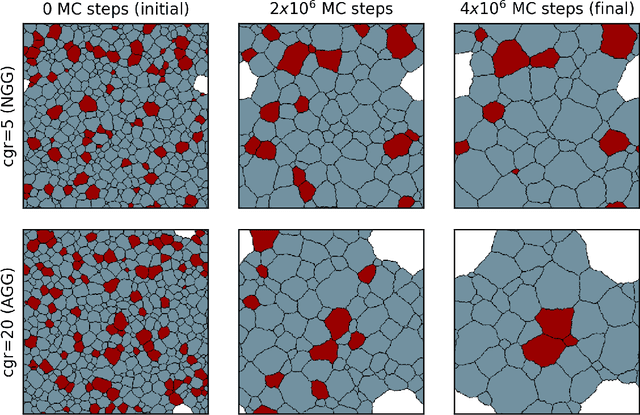

Abstract:Abnormal grain growth can significantly alter the properties of materials during processing. This can cause significant variation in the properties and performance of in-spec feedstock components subjected to identical processing paths. Understanding and controlling abnormal grain growth has proved to be elusive due to the stochastic nature of this phenomenon. However, recent advances in deep learning provide a promising alternative to traditional experimental and physics-based methods for understanding this phenomenon. Neural message passing allows deep learning to be applied to irregular inputs including graph representations of grain structures in a material. In this study we generate a large database of Monte Carlo simulations of abnormal grain growth in an idealized system. We apply message passing neural networks to predict the occurrence of abnormal grain growth in these simulations using only the initial state of the system as input. A computer vision model is also trained for the same task for comparison. The preliminary results indicate that the message passing approach outperforms the computer vision method and achieved 75% prediction accuracy, significantly better than random guessing. Analysis of the uncertainty in the Monte Carlo simulations provides a road map for ongoing work on this project.

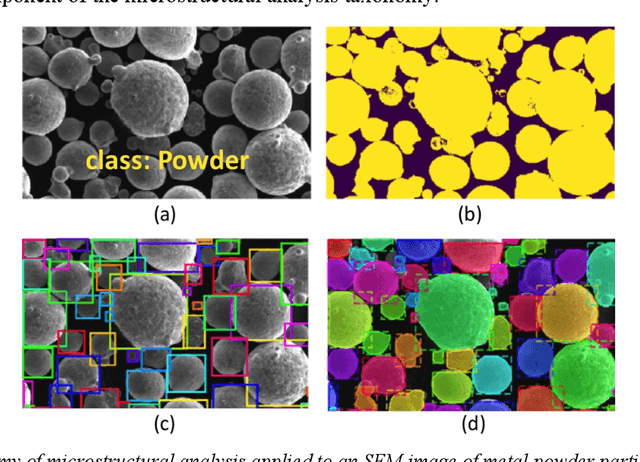

Instance Segmentation for Direct Measurements of Satellites in Metal Powders and Automated Microstructural Characterization from Image Data

Jan 05, 2021

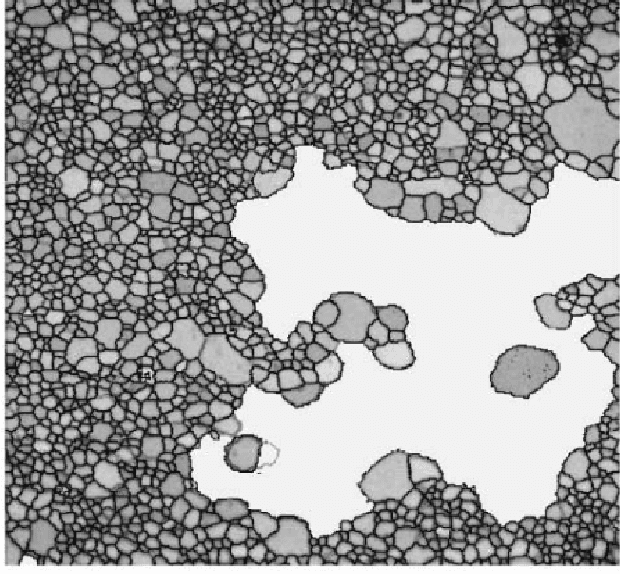

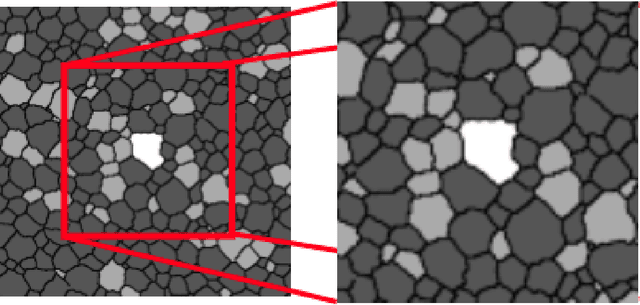

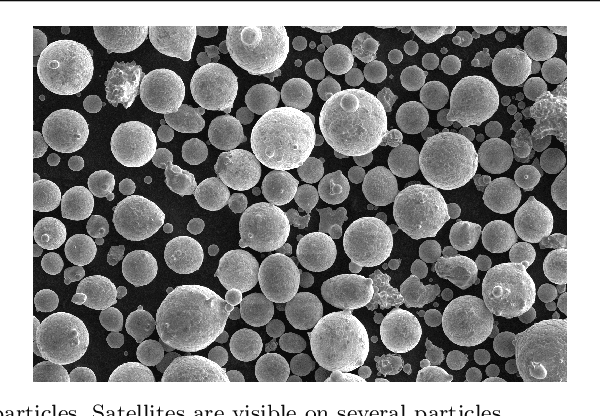

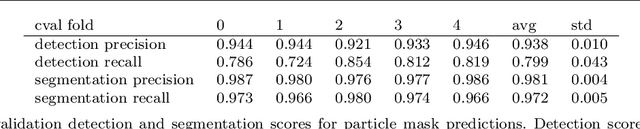

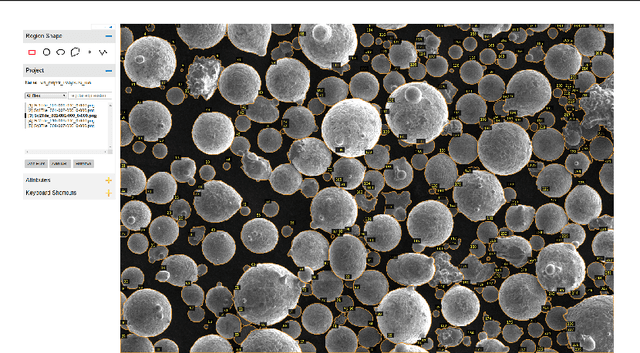

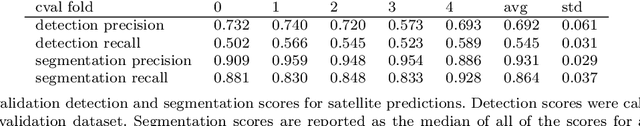

Abstract:We propose instance segmentation as a useful tool for image analysis in materials science. Instance segmentation is an advanced technique in computer vision which generates individual segmentation masks for every object of interest that is recognized in an image. Using an out-of-the-box implementation of Mask R-CNN, instance segmentation is applied to images of metal powder particles produced through gas atomization. Leveraging transfer learning allows for the analysis to be conducted with a very small training set of labeled images. As well as providing another method for measuring the particle size distribution, we demonstrate the first direct measurements of the satellite content in powder samples. After analyzing the results for the labeled data dataset, the trained model was used to generate measurements for a much larger set of unlabeled images. The resulting particle size measurements showed reasonable agreement with laser scattering measurements. The satellite measurements were self-consistent and showed good agreement with the expected trends for different samples. Finally, we provide a small case study showing how instance segmentation can be used to measure spheroidite content in the UltraHigh Carbon Steel Database, demonstrating the flexibility of the technique.

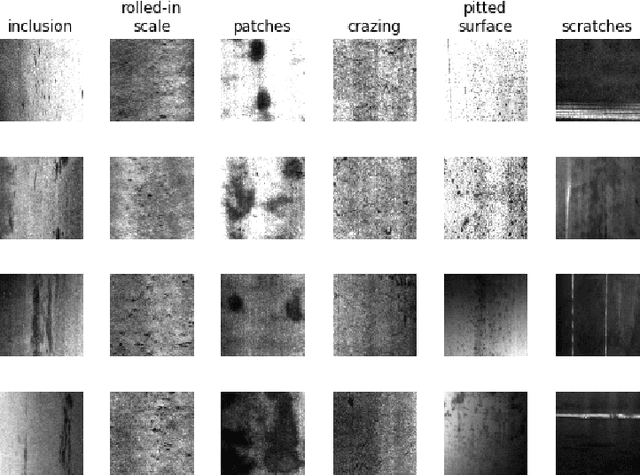

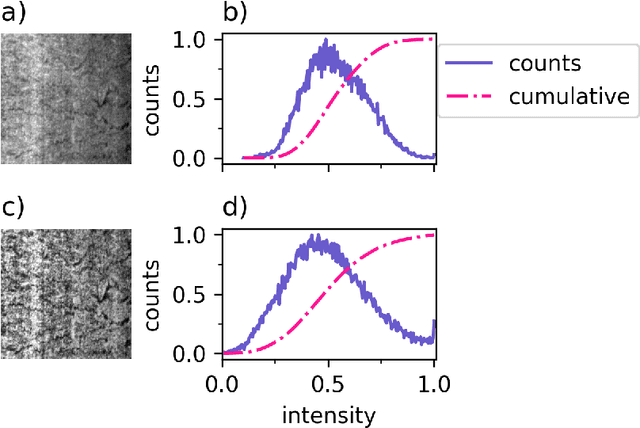

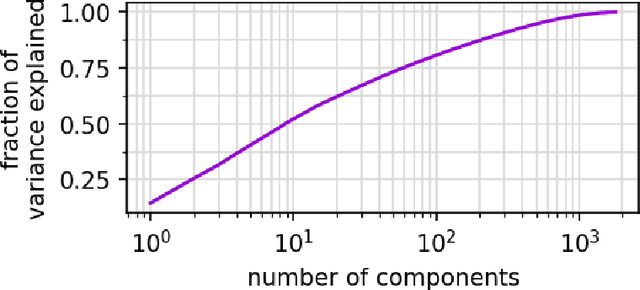

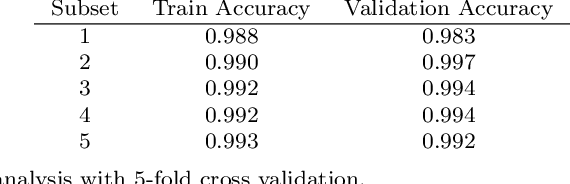

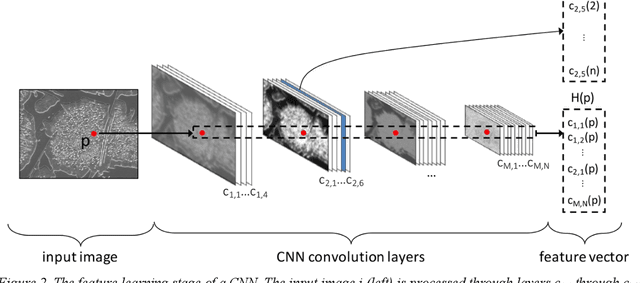

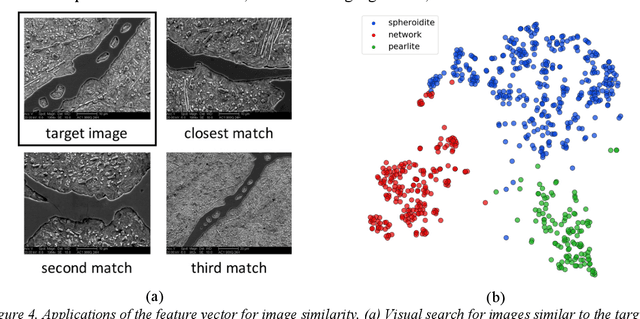

Unsupervised machine learning via transfer learning and k-means clustering to classify materials image data

Jul 16, 2020

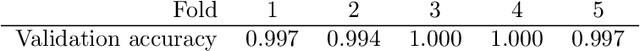

Abstract:Unsupervised machine learning offers significant opportunities for extracting knowledge from unlabeled data sets and for achieving maximum machine learning performance. This paper demonstrates how to construct, use, and evaluate a high performance unsupervised machine learning system for classifying images in a popular microstructural dataset. The Northeastern University Steel Surface Defects Database includes micrographs of six different defects observed on hot-rolled steel in a format that is convenient for training and evaluating models for image classification. We use the VGG16 convolutional neural network pre-trained on the ImageNet dataset of natural images to extract feature representations for each micrograph. After applying principal component analysis to extract signal from the feature descriptors, we use k-means clustering to classify the images without needing labeled training data. The approach achieves $99.4\% \pm 0.16\%$ accuracy, and the resulting model can be used to classify new images without retraining This approach demonstrates an improvement in both performance and utility compared to a previous study. A sensitivity analysis is conducted to better understand the influence of each step on the classification performance. The results provide insight toward applying unsupervised machine learning techniques to problems of interest in materials science.

Overview: Computer vision and machine learning for microstructural characterization and analysis

May 28, 2020

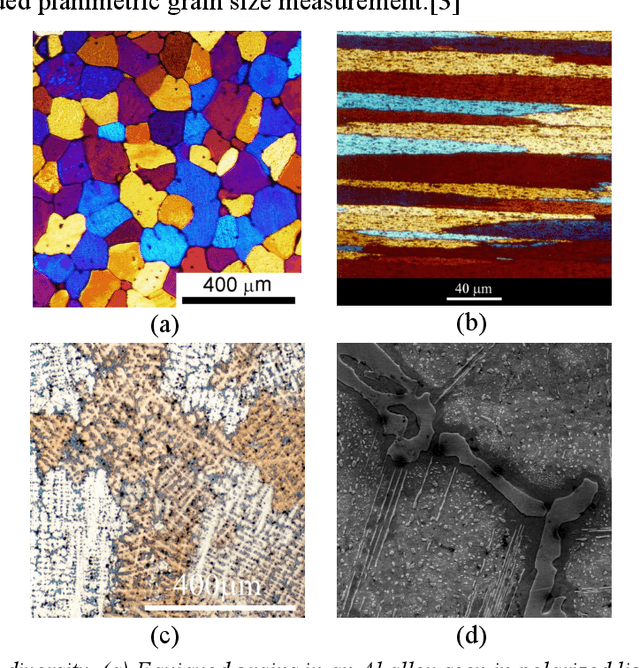

Abstract:The characterization and analysis of microstructure is the foundation of microstructural science, connecting the materials structure to its composition, process history, and properties. Microstructural quantification traditionally involves a human deciding a priori what to measure and then devising a purpose-built method for doing so. However, recent advances in data science, including computer vision (CV) and machine learning (ML) offer new approaches to extracting information from microstructural images. This overview surveys CV approaches to numerically encode the visual information contained in a microstructural image, which then provides input to supervised or unsupervised ML algorithms that find associations and trends in the high-dimensional image representation. CV/ML systems for microstructural characterization and analysis span the taxonomy of image analysis tasks, including image classification, semantic segmentation, object detection, and instance segmentation. These tools enable new approaches to microstructural analysis, including the development of new, rich visual metrics and the discovery of processing-microstructure-property relationships.

Add to Chrome

Add to Chrome Add to Firefox

Add to Firefox Add to Edge

Add to Edge