Dylan Shah

Data-driven Kinematic Modeling in Soft Robots: System Identification and Uncertainty Quantification

Jul 10, 2025Abstract:Precise kinematic modeling is critical in calibration and controller design for soft robots, yet remains a challenging issue due to their highly nonlinear and complex behaviors. To tackle the issue, numerous data-driven machine learning approaches have been proposed for modeling nonlinear dynamics. However, these models suffer from prediction uncertainty that can negatively affect modeling accuracy, and uncertainty quantification for kinematic modeling in soft robots is underexplored. In this work, using limited simulation and real-world data, we first investigate multiple linear and nonlinear machine learning models commonly used for kinematic modeling of soft robots. The results reveal that nonlinear ensemble methods exhibit the most robust generalization performance. We then develop a conformal kinematic modeling framework for soft robots by utilizing split conformal prediction to quantify predictive position uncertainty, ensuring distribution-free prediction intervals with a theoretical guarantee.

Scalable sim-to-real transfer of soft robot designs

Nov 23, 2019

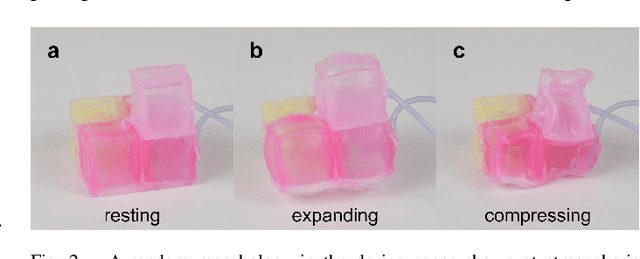

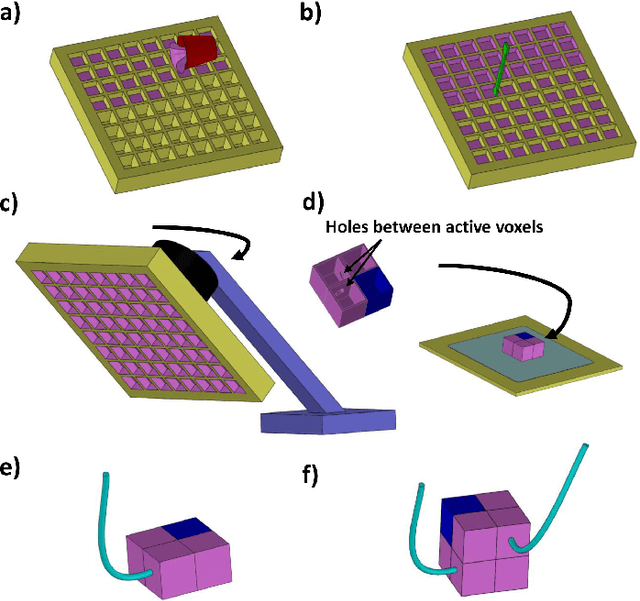

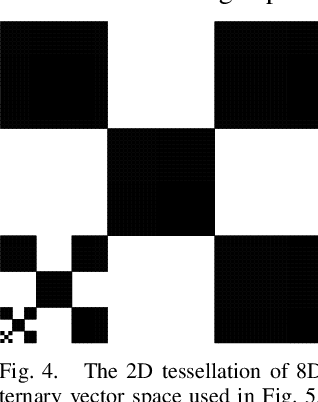

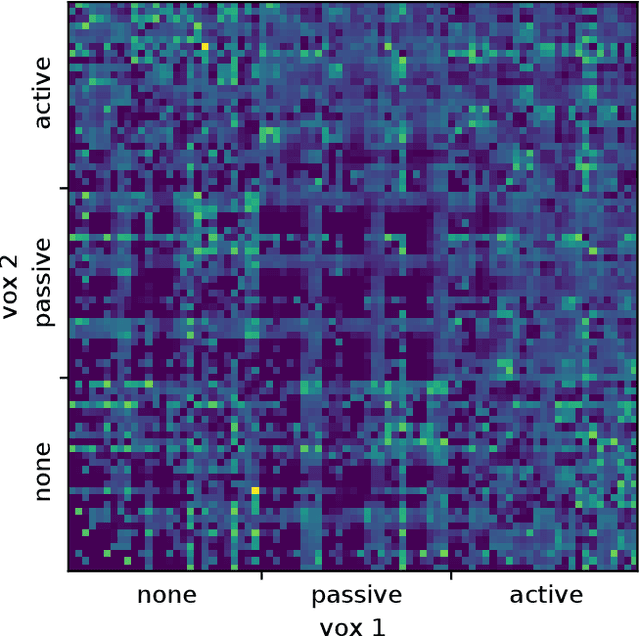

Abstract:The manual design of soft robots and their controllers is notoriously challenging, but it could be augmented---or, in some cases, entirely replaced---by automated design tools. Machine learning algorithms can automatically propose, test, and refine designs in simulation, and the most promising ones can then be manufactured in reality (sim2real). However, it is currently not known how to guarantee that behavior generated in simulation can be preserved when deployed in reality. Although many previous studies have devised training protocols that facilitate sim2real transfer of control polices, little to no work has investigated the simulation-reality gap as a function of morphology. This is due in part to an overall lack of tools capable of systematically designing and rapidly manufacturing robots. Here we introduce a low cost, open source, and modular soft robot design and construction kit, and use it to simulate, fabricate, and measure the simulation-reality gap of minimally complex yet soft, locomoting machines. We prove the scalability of this approach by transferring an order of magnitude more robot designs from simulation to reality than any other method. The kit and its instructions can be found here: https://github.com/skriegman/sim2real4designs

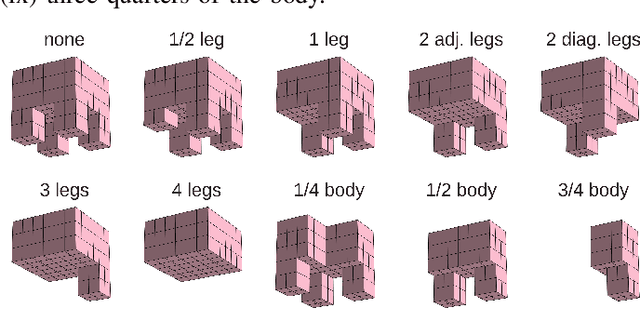

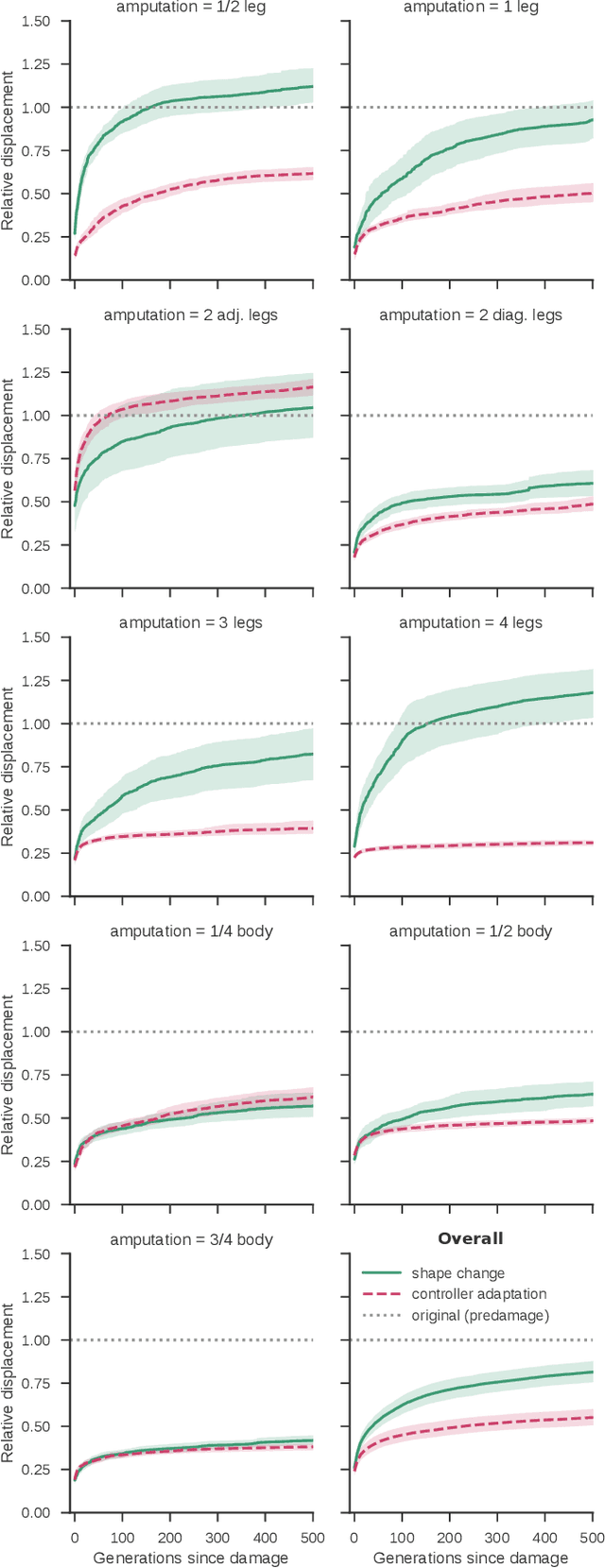

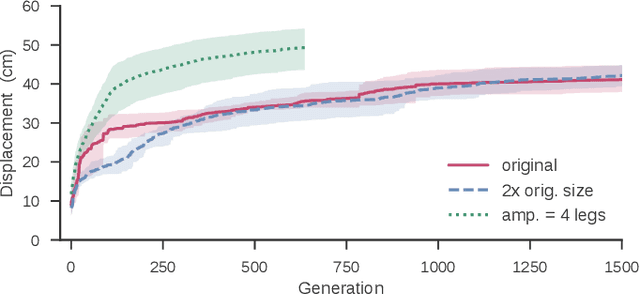

Automated shapeshifting for function recovery in damaged robots

May 22, 2019

Abstract:A robot's mechanical parts routinely wear out from normal functioning and can be lost to injury. For autonomous robots operating in isolated or hostile environments, repair from a human operator is often not possible. Thus, much work has sought to automate damage recovery in robots. However, every case reported in the literature to date has accepted the damaged mechanical structure as fixed, and focused on learning new ways to control it. Here we show for the first time a robot that automatically recovers from unexpected damage by deforming its resting mechanical structure without changing its control policy. We found that, especially in the case of "deep insult", such as removal of all four of the robot's legs, the damaged machine evolves shape changes that not only recover the original level of function (locomotion) as before, but can in fact surpass the original level of performance (speed). This suggests that shape change, instead of control readaptation, may be a better method to recover function after damage in some cases.

Add to Chrome

Add to Chrome Add to Firefox

Add to Firefox Add to Edge

Add to Edge