Dawood Ahmed

Adaptive Vision-Guided Robotic Arm Control for Precision Pruning in Dynamic Orchard Environments

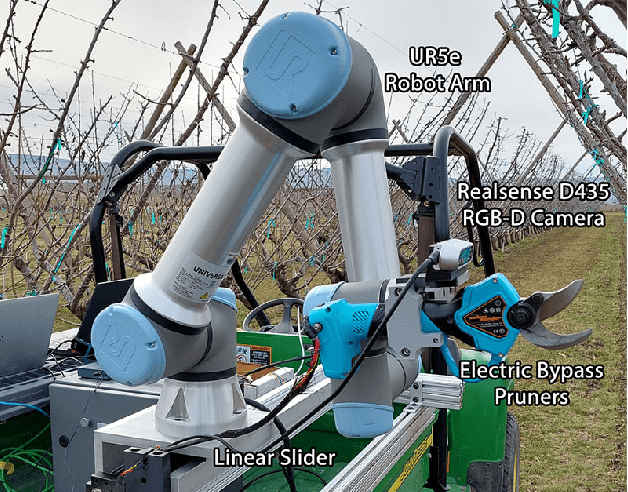

Apr 09, 2025Abstract:This study presents a vision-guided robotic control system for automated fruit tree pruning applications. Traditional agricultural practices rely on labor-intensive tasks and processes that lack scalability and efficiency, creating a pressing need for automation research to address growing demands for higher crop yields, scalable operations, and reduced manual labor. To this end, this paper proposes a novel algorithm for robust and automated fruit pruning in dense orchards. The proposed algorithm utilizes CoTracker, that is designed to track 2D feature points in video sequences with significant robustness and accuracy, while leveraging joint attention mechanisms to account for inter-point dependencies, enabling robust and precise tracking under challenging and sophisticated conditions. To validate the efficacy of CoTracker, a Universal Robots manipulator UR5e is employed in a Gazebo simulation environment mounted on ClearPath Robotics Warthog robot featuring an Intel RealSense D435 camera. The system achieved a 93% success rate in pruning trials and with an average end trajectory error of 0.23 mm. The vision controller demonstrated robust performance in handling occlusions and maintaining stable trajectories as the arm move towards the target point. The results validate the effectiveness of integrating vision-based tracking with kinematic control for precision agricultural tasks. Future work will focus on real-world implementation and the integration of 3D reconstruction techniques for enhanced adaptability in dynamic environments.

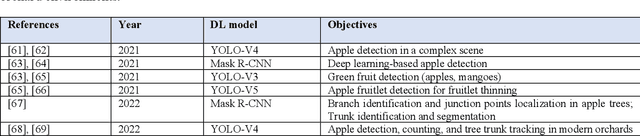

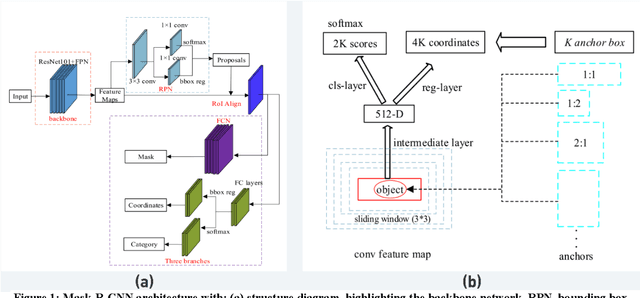

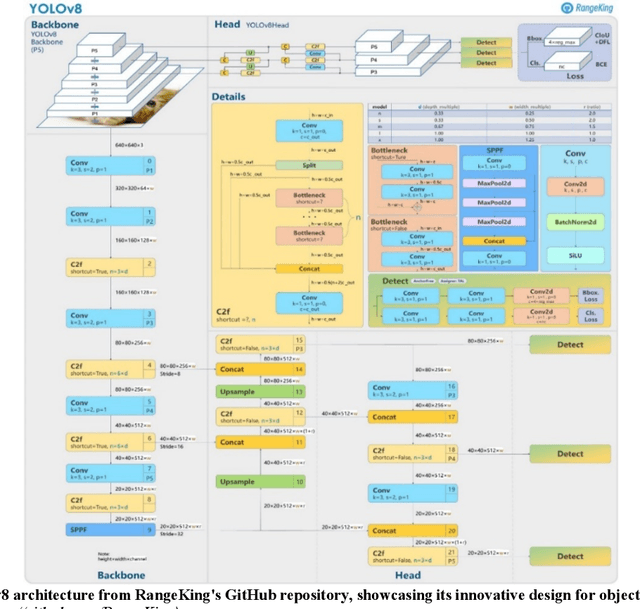

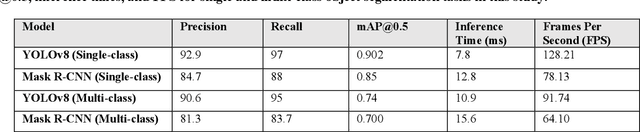

Comparing YOLOv8 and Mask RCNN for object segmentation in complex orchard environments

Dec 27, 2023

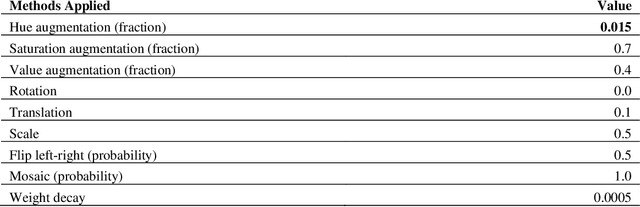

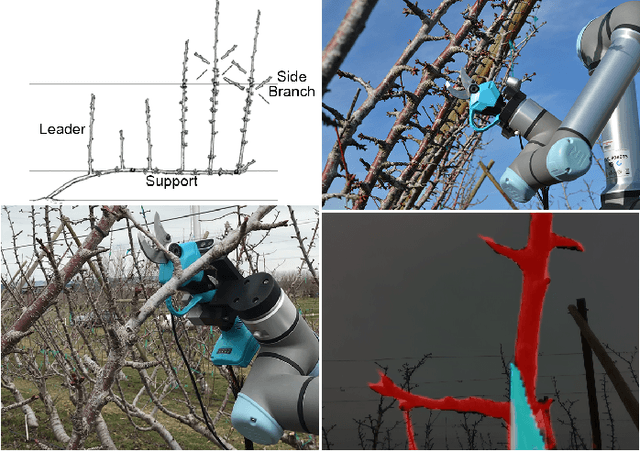

Abstract:Instance segmentation, an important image processing operation for automation in agriculture, is used to precisely delineate individual objects of interest within images, which provides foundational information for various automated or robotic tasks such as selective harvesting and precision pruning. This study compares the one-stage YOLOv8 and the two-stage Mask R-CNN machine learning models for instance segmentation under varying orchard conditions across two datasets. Dataset 1, collected in dormant season, includes images of dormant apple trees, which were used to train multi-object segmentation models delineating tree branches and trunks. Dataset 2, collected in the early growing season, includes images of apple tree canopies with green foliage and immature (green) apples (also called fruitlet), which were used to train single-object segmentation models delineating only immature green apples. The results showed that YOLOv8 performed better than Mask R-CNN, achieving good precision and near-perfect recall across both datasets at a confidence threshold of 0.5. Specifically, for Dataset 1, YOLOv8 achieved a precision of 0.90 and a recall of 0.95 for all classes. In comparison, Mask R-CNN demonstrated a precision of 0.81 and a recall of 0.81 for the same dataset. With Dataset 2, YOLOv8 achieved a precision of 0.93 and a recall of 0.97. Mask R-CNN, in this single-class scenario, achieved a precision of 0.85 and a recall of 0.88. Additionally, the inference times for YOLOv8 were 10.9 ms for multi-class segmentation (Dataset 1) and 7.8 ms for single-class segmentation (Dataset 2), compared to 15.6 ms and 12.8 ms achieved by Mask R-CNN's, respectively.

Robotic Pollination of Apples in Commercial Orchards

Nov 21, 2023

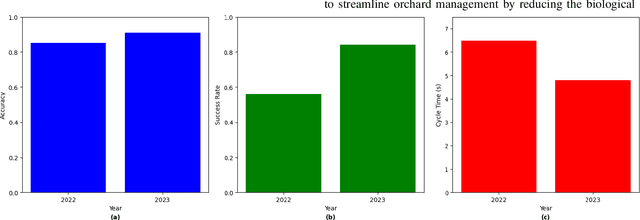

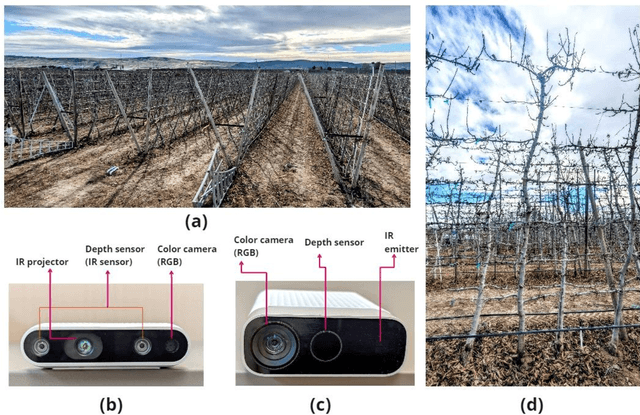

Abstract:This research presents a novel, robotic pollination system designed for targeted pollination of apple flowers in modern fruiting wall orchards. Developed in response to the challenges of global colony collapse disorder, climate change, and the need for sustainable alternatives to traditional pollinators, the system utilizes a commercial manipulator, a vision system, and a spray nozzle for pollen application. Initial tests in April 2022 pollinated 56% of the target flower clusters with at least one fruit with a cycle time of 6.5 s. Significant improvements were made in 2023, with the system accurately detecting 91% of available flowers and pollinating 84% of target flowers with a reduced cycle time of 4.8 s. This system showed potential for precision artificial pollination that can also minimize the need for labor-intensive field operations such as flower and fruitlet thinning.

Machine Vision-Based Crop-Load Estimation Using YOLOv8

Apr 26, 2023

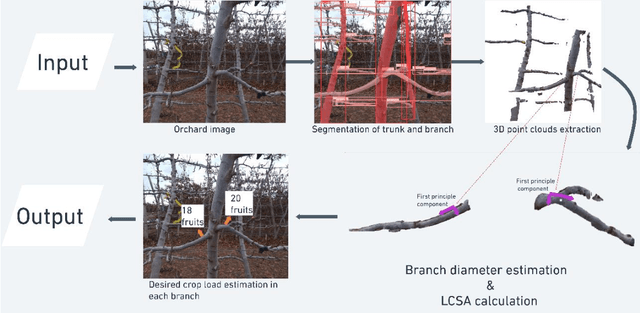

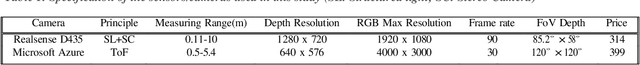

Abstract:Labor shortages in fruit crop production have prompted the development of mechanized and automated machines as alternatives to labor-intensive orchard operations such as harvesting, pruning, and thinning. Agricultural robots capable of identifying tree canopy parts and estimating geometric and topological parameters, such as branch diameter, length, and angles, can optimize crop yields through automated pruning and thinning platforms. In this study, we proposed a machine vision system to estimate canopy parameters in apple orchards and determine an optimal number of fruit for individual branches, providing a foundation for robotic pruning, flower thinning, and fruitlet thinning to achieve desired yield and quality.Using color and depth information from an RGB-D sensor (Microsoft Azure Kinect DK), a YOLOv8-based instance segmentation technique was developed to identify trunks and branches of apple trees during the dormant season. Principal Component Analysis was applied to estimate branch diameter (used to calculate limb cross-sectional area, or LCSA) and orientation. The estimated branch diameter was utilized to calculate LCSA, which served as an input for crop-load estimation, with larger LCSA values indicating a higher potential fruit-bearing capacity.RMSE for branch diameter estimation was 2.08 mm, and for crop-load estimation, 3.95. Based on commercial apple orchard management practices, the target crop-load (number of fruit) for each segmented branch was estimated with a mean absolute error (MAE) of 2.99 (ground truth crop-load was 6 apples per LCSA). This study demonstrated a promising workflow with high performance in identifying trunks and branches of apple trees in dynamic commercial orchard environments and integrating farm management practices into automated decision-making.

Machine Vision System for Early-stage Apple Flowers and Flower Clusters Detection for Precision Thinning and Pollination

Apr 19, 2023Abstract:Early-stage identification of fruit flowers that are in both opened and unopened condition in an orchard environment is significant information to perform crop load management operations such as flower thinning and pollination using automated and robotic platforms. These operations are important in tree-fruit agriculture to enhance fruit quality, manage crop load, and enhance the overall profit. The recent development in agricultural automation suggests that this can be done using robotics which includes machine vision technology. In this article, we proposed a vision system that detects early-stage flowers in an unstructured orchard environment using YOLOv5 object detection algorithm. For the robotics implementation, the position of a cluster of the flower blossom is important to navigate the robot and the end effector. The centroid of individual flowers (both open and unopen) was identified and associated with flower clusters via K-means clustering. The accuracy of the opened and unopened flower detection is achieved up to mAP of 81.9% in commercial orchard images.

An autonomous robot for pruning modern, planar fruit trees

Jun 14, 2022

Abstract:Dormant pruning of fruit trees is an important task for maintaining tree health and ensuring high-quality fruit. Due to decreasing labor availability, pruning is a prime candidate for robotic automation. However, pruning also represents a uniquely difficult problem for robots, requiring robust systems for perception, pruning point determination, and manipulation that must operate under variable lighting conditions and in complex, highly unstructured environments. In this paper, we introduce a system for pruning sweet cherry trees (in a planar tree architecture called an upright fruiting offshoot configuration) that integrates various subsystems from our previous work on perception and manipulation. The resulting system is capable of operating completely autonomously and requires minimal control of the environment. We validate the performance of our system through field trials in a sweet cherry orchard, ultimately achieving a cutting success rate of 58%. Though not fully robust and requiring improvements in throughput, our system is the first to operate on fruit trees and represents a useful base platform to be improved in the future.

Add to Chrome

Add to Chrome Add to Firefox

Add to Firefox Add to Edge

Add to Edge