Daniel Kanaan

IRCCyN

Multi-Objective Design Optimization of the Leg Mechanism for a Piping Inspection Robot

Jun 18, 2014

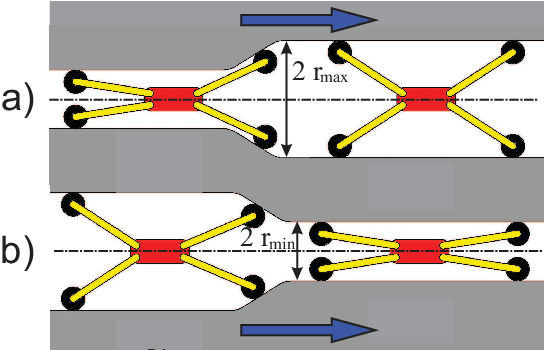

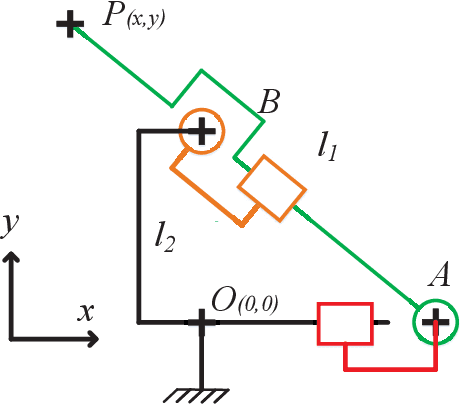

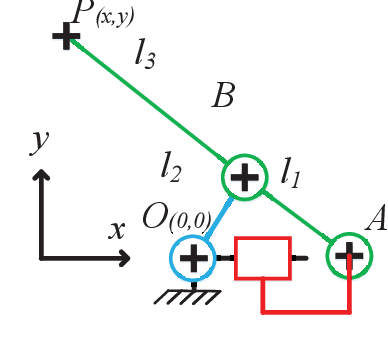

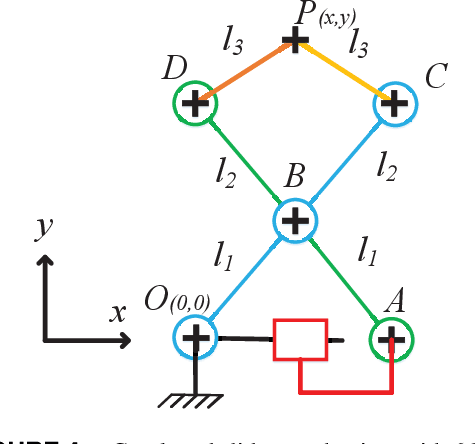

Abstract:This paper addresses the dimensional synthesis of an adaptive mechanism of contact points ie a leg mechanism of a piping inspection robot operating in an irradiated area as a nuclear power plant. This studied mechanism is the leading part of the robot sub-system responsible of the locomotion. Firstly, three architectures are chosen from the literature and their properties are described. Then, a method using a multi-objective optimization is proposed to determine the best architecture and the optimal geometric parameters of a leg taking into account environmental and design constraints. In this context, the objective functions are the minimization of the mechanism size and the maximization of the transmission force factor. Representations of the Pareto front versus the objective functions and the design parameters are given. Finally, the CAD model of several solutions located on the Pareto front are presented and discussed.

Singularity Analysis of Lower-Mobility Parallel Manipulators Using Grassmann-Cayley Algebra

Oct 21, 2009

Abstract:This paper introduces a methodology to analyze geometrically the singularities of manipulators, of which legs apply both actuation forces and constraint moments to their moving platform. Lower-mobility parallel manipulators and parallel manipulators, of which some legs do not have any spherical joint, are such manipulators. The geometric conditions associated with the dependency of six Pl\"ucker vectors of finite lines or lines at infinity constituting the rows of the inverse Jacobian matrix are formulated using Grassmann-Cayley Algebra. Accordingly, the singularity conditions are obtained in vector form. This study is illustrated with the singularity analysis of four manipulators.

Kinematic Analysis of a Serial - Parallel Machine Tool: the VERNE machine

Nov 28, 2008

Abstract:The paper derives the inverse and the forward kinematic equations of a serial - parallel 5-axis machine tool: the VERNE machine. This machine is composed of a three-degree-of-freedom (DOF) parallel module and a two-DOF serial tilting table. The parallel module consists of a moving platform that is connected to a fixed base by three non-identical legs. These legs are connected in a way that the combined effects of the three legs lead to an over-constrained mechanism with complex motion. This motion is defined as a simultaneous combination of rotation and translation. In this paper we propose symbolical methods that able to calculate all kinematic solutions and identify the acceptable one by adding analytical constraint on the disposition of legs of the parallel module.

Singularity Analysis of Limited-dof Parallel Manipulators using Grassmann-Cayley Algebra

Sep 18, 2008

Abstract:This paper characterizes geometrically the singularities of limited DOF parallel manipulators. The geometric conditions associated with the dependency of six Pl\"ucker vector of lines (finite and infinite) constituting the rows of the inverse Jacobian matrix are formulated using Grassmann-Cayley algebra. Manipulators under consideration do not need to have a passive spherical joint somewhere in each leg. This study is illustrated with three example robots

Workspace and Kinematic Analysis of the VERNE machine

Jul 24, 2007

Abstract:This paper describes the workspace and the inverse and direct kinematic analysis of the VERNE machine, a serial/parallel 5-axis machine tool designed by Fatronik for IRCCyN. This machine is composed of a three-degree-of-freedom (DOF) parallel module and a two-DOF serial tilting table. The parallel module consists of a moving platform that is connected to a fixed base by three non-identical legs. This feature involves (i) a simultaneous combination of rotation and translation for the moving platform, which is balanced by the tilting table and (ii) workspace whose shape and volume vary as a function of the tool length. This paper summarizes results obtained in the context of the European projects NEXT ("Next Generation of Productions Systems").

Workspace Analysis of the Parallel Module of the VERNE Machine

Jul 05, 2007

Abstract:The paper addresses geometric aspects of a spatial three-degree-of-freedom parallel module, which is the parallel module of a hybrid serial-parallel 5-axis machine tool. This parallel module consists of a moving platform that is connected to a fixed base by three non-identical legs. Each leg is made up of one prismatic and two pairs of spherical joint, which are connected in a way that the combined effects of the three legs lead to an over-constrained mechanism with complex motion. This motion is defined as a simultaneous combination of rotation and translation. A method for computing the complete workspace of the VERNE parallel module for various tool lengths is presented. An algorithm describing this method is also introduced.

Kinematics analysis of the parallel module of the VERNE machine

May 10, 2007

Abstract:The paper derives the inverse and forward kinematic equations of a spatial three-degree-of-freedom parallel mechanism, which is the parallel module of a hybrid serial-parallel 5-axis machine tool. This parallel mechanism consists of a moving platform that is connected to a fixed base by three non-identical legs. Each leg is made up of one prismatic and two pair spherical joint, which are connected in a way that the combined effects of the three legs lead to an over-constrained mechanism with complex motion. This motion is defined as a simultaneous combination of rotation and translation.

Add to Chrome

Add to Chrome Add to Firefox

Add to Firefox Add to Edge

Add to Edge