Chenang Liu

ADs: Active Data-sharing for Data Quality Assurance in Advanced Manufacturing Systems

Mar 31, 2024

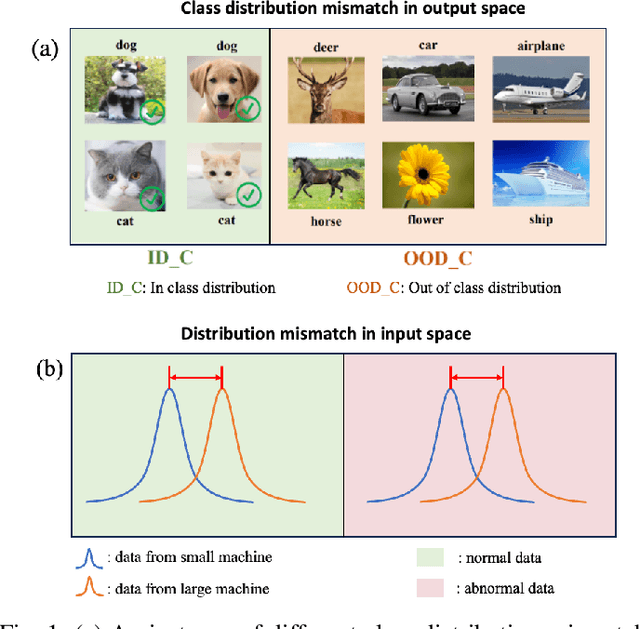

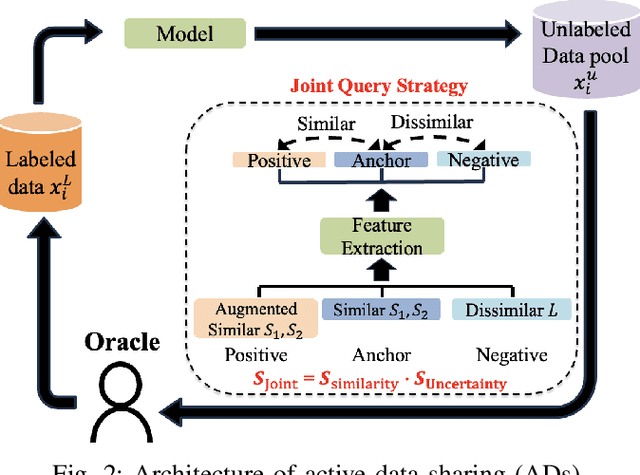

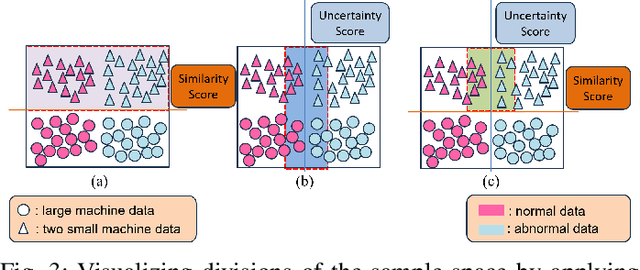

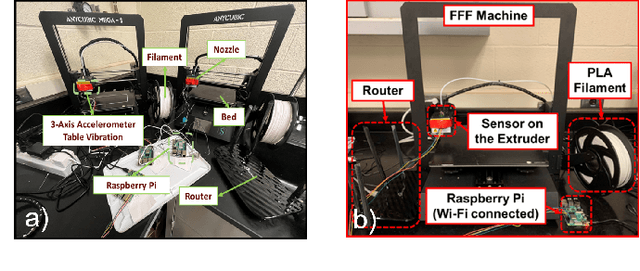

Abstract:Machine learning (ML) methods are widely used in industrial applications, which usually require a large amount of training data. However, data collection needs extensive time costs and investments in the manufacturing system, and data scarcity commonly exists. Therefore, data-sharing is widely enabled among multiple machines with similar functionality to augment the dataset for building ML methods. However, distribution mismatch inevitably exists in their data due to different working conditions, while the ML methods are assumed to be built and tested on the dataset following the same distribution. Thus, an Active Data-sharing (ADs) framework is proposed to ensure the quality of the shared data among multiple machines. It is designed to simultaneously select the most informative data points benefiting the downstream tasks and mitigate the distribution mismatch among all selected data points. The proposed method is validated on anomaly detection on in-situ monitoring data from three additive manufacturing processes.

Advancing Additive Manufacturing through Deep Learning: A Comprehensive Review of Current Progress and Future Challenges

Mar 01, 2024

Abstract:Additive manufacturing (AM) has already proved itself to be the potential alternative to widely-used subtractive manufacturing due to its extraordinary capacity of manufacturing highly customized products with minimum material wastage. Nevertheless, it is still not being considered as the primary choice for the industry due to some of its major inherent challenges, including complex and dynamic process interactions, which are sometimes difficult to fully understand even with traditional machine learning because of the involvement of high-dimensional data such as images, point clouds, and voxels. However, the recent emergence of deep learning (DL) is showing great promise in overcoming many of these challenges as DL can automatically capture complex relationships from high-dimensional data without hand-crafted feature extraction. Therefore, the volume of research in the intersection of AM and DL is exponentially growing each year which makes it difficult for the researchers to keep track of the trend and future potential directions. Furthermore, to the best of our knowledge, there is no comprehensive review paper in this research track summarizing the recent studies. Therefore, this paper reviews the recent studies that apply DL for making the AM process better with a high-level summary of their contributions and limitations. Finally, it summarizes the current challenges and recommends some of the promising opportunities in this domain for further investigation with a special focus on generalizing DL models for wide-range of geometry types, managing uncertainties both in AM data and DL models, overcoming limited and noisy AM data issues by incorporating generative models, and unveiling the potential of interpretable DL for AM.

Pseudo Replay-based Class Continual Learning for Online New Category Anomaly Detection in Additive Manufacturing

Dec 05, 2023

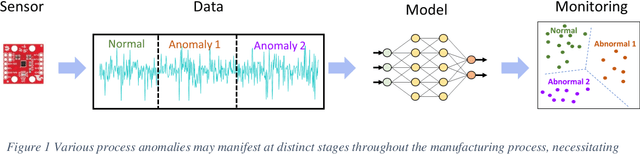

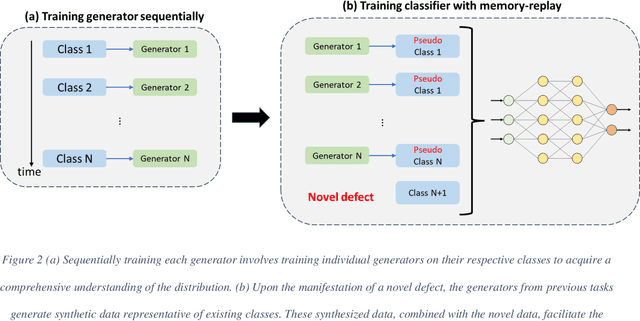

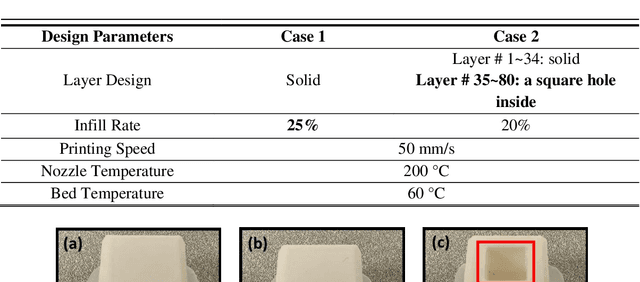

Abstract:The incorporation of advanced sensors and machine learning techniques has enabled modern manufacturing enterprises to perform data-driven in-situ quality monitoring based on the sensor data collected in manufacturing processes. However, one critical challenge is that newly presented defect category may manifest as the manufacturing process continues, resulting in monitoring performance deterioration of previously trained machine learning models. Hence, there is an increasing need for empowering machine learning model to learn continually. Among all continual learning methods, memory-based continual learning has the best performance but faces the constraints of data storage capacity. To address this issue, this paper develops a novel pseudo replay-based continual learning by integrating class incremental learning and oversampling-based data generation. Without storing all the data, the developed framework could generate high-quality data representing previous classes to train machine learning model incrementally when new category anomaly occurs. In addition, it could even enhance the monitoring performance since it also effectively improves the data quality. The effectiveness of the proposed framework is validated in an additive manufacturing process, which leverages supervised classification problem for anomaly detection. The experimental results show that the developed method is very promising in detecting novel anomaly while maintaining a good performance on the previous task and brings up more flexibility in model architecture.

Attention-stacked Generative Adversarial Network (AS-GAN)-empowered Sensor Data Augmentation for Online Monitoring of Manufacturing System

Jun 09, 2023

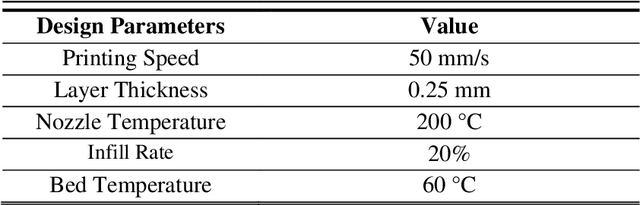

Abstract:Machine learning (ML) has been extensively adopted for the online sensing-based monitoring in advanced manufacturing systems. However, the sensor data collected under abnormal states are usually insufficient, leading to significant data imbalanced issue for supervised machine learning. A common solution for this issue is to incorporate data augmentation technique, i.e., augmenting the available abnormal states data (i.e., minority samples) via synthetic generation. To generate the high-quality minority samples effectively, it is vital to learn the underlying distribution of the abnormal states data. In recent years, the generative adversarial network (GAN)-based approaches become popular to learn data distribution as well as perform data augmentation. However, in practice, the quality of generated samples from GAN-based data augmentation may vary drastically. In addition, the sensor signals are collected sequentially by time from the manufacturing systems, which means the consideration of sequential information is also very important in data augmentation. To address these limitations, inspired by the multi-head attention mechanism, this paper proposed an attention-stacked GAN (AS-GAN) architecture for the sensor data augmentation of online monitoring in advanced manufacturing. In this proposed AS-GAN, a new attention-stacked framework is incorporated to strengthen the generator in GAN with the learning capability of considering sequential information. Furthermore, the developed attention-stacked framework also greatly helps to improve the quality of generated sensor signals. The case studies conducted in additive manufacturing also successfully validate the effectiveness of AS-GAN to augment high-quality artificial multi-channel sensor signals for online monitoring of manufacturing systems.

Knowledge Distillation-based Information Sharing for Online Process Monitoring in Decentralized Manufacturing System

Feb 08, 2023Abstract:In advanced manufacturing, the incorporation of sensing technology provides an opportunity to achieve efficient in-situ process monitoring using machine learning methods. Meanwhile, the advances of information technologies also enable a connected and decentralized environment for manufacturing systems, making different manufacturing units in the system collaborate more closely. In a decentralized manufacturing system, the involved units may fabricate same or similar products and deploy their own machine learning model for online process monitoring. However, due to the possible inconsistency of task progress during the operation, it is also common that some units are data-rich while some are data-poor. Thus, the learning progress of the machine learning-based process monitoring model for each unit may vary. Therefore, it is highly valuable to achieve efficient and secured knowledge sharing among the units in a decentralized manufacturing system. To realize this goal, this paper proposes a knowledge distillation-based information sharing (KD-IS) framework, which could distill informative knowledge from data-rich unit to improve the monitoring performance of data-poor unit. To validate the effectiveness of this method, a real-world case study is conducted in a connected fused filament fabrication (FFF)-based additive manufacturing (AM) platform. The experimental results show that the developed method is efficient in improving model monitoring performance at data-poor unit, with solid protection on potential data privacy.

Model-Informed Generative Adversarial Network (MI-GAN) for Learning Optimal Power Flow

Jun 04, 2022

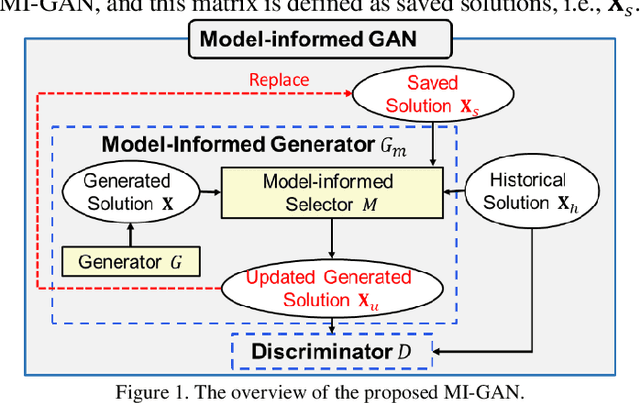

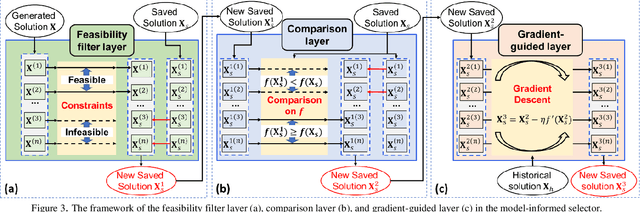

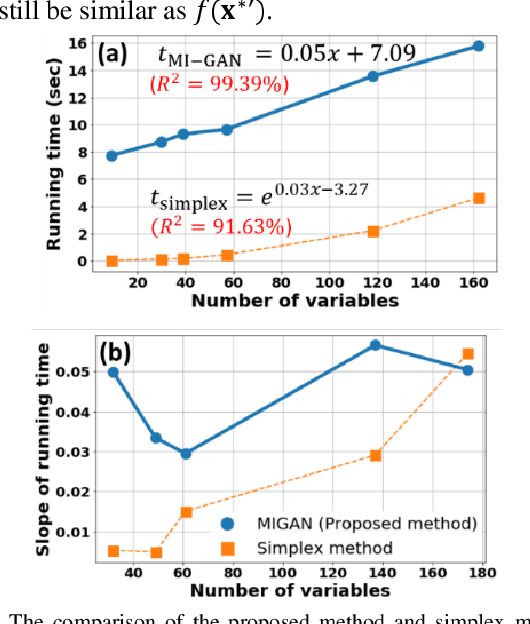

Abstract:The optimal power flow (OPF) problem, as a critical component of power system operations, becomes increasingly difficult to solve due to the variability, intermittency, and unpredictability of renewable energy brought to the power system. Although traditional optimization techniques, such as stochastic and robust optimization approaches, could be used to address the OPF problem in the face of renewable energy uncertainty, their effectiveness in dealing with large-scale problems remains limited. As a result, deep learning techniques, such as neural networks, have recently been developed to improve computational efficiency in solving large-scale OPF problems. However, the feasibility and optimality of the solution may not be guaranteed. In this paper, we propose an optimization model-informed generative adversarial network (MI-GAN) framework to solve OPF under uncertainty. The main contributions are summarized into three aspects: (1) to ensure feasibility and improve optimality of generated solutions, three important layers are proposed: feasibility filter layer, comparison layer, and gradient-guided layer; (2) in the GAN-based framework, an efficient model-informed selector incorporating these three new layers is established; and (3) a new recursive iteration algorithm is also proposed to improve solution optimality. The numerical results on IEEE test systems show that the proposed method is very effective and promising.

A Generative Adversarial Network-based Selective Ensemble Characteristic-to-Expression Synthesis (SE-CTES) Approach and Its Applications in Healthcare

May 29, 2022

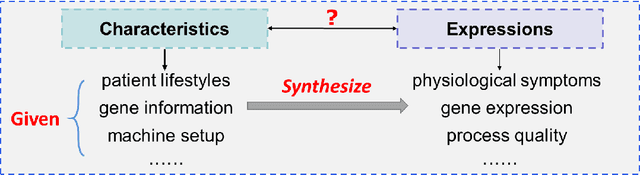

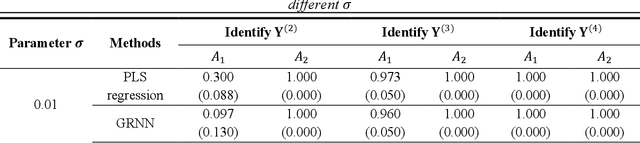

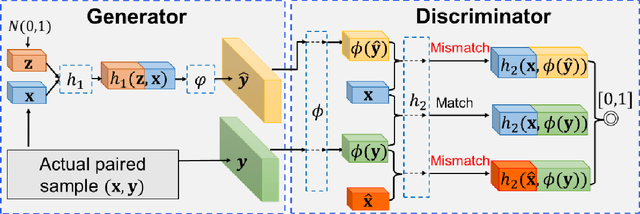

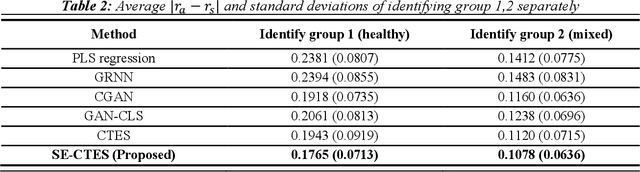

Abstract:Investigating the causal relationships between characteristics and expressions plays a critical role in healthcare analytics. Effective synthesis for expressions using given characteristics can make great contributions to health risk management and medical decision-making. For example, predicting the resulting physiological symptoms on patients from given treatment characteristics is helpful for the disease prevention and personalized treatment strategy design. Therefore, the objective of this study is to effectively synthesize the expressions based on given characteristics. However, the mapping from characteristics to expressions is usually from a relatively low dimension space to a high dimension space, but most of the existing methods such as regression models could not effectively handle such mapping. Besides, the relationship between characteristics and expressions may contain not only deterministic patterns, but also stochastic patterns. To address these challenges, this paper proposed a novel selective ensemble characteristic-to-expression synthesis (SE-CTES) approach inspired by generative adversarial network (GAN). The novelty of the proposed method can be summarized into three aspects: (1) GAN-based architecture for deep neural networks are incorporated to learn the relatively low dimensional mapping to high dimensional mapping containing both deterministic and stochastic patterns; (2) the weights of the two mismatching errors in the GAN-based architecture are proposed to be different to reduce the learning bias in the training process; and (3) a selective ensemble learning framework is proposed to reduce the prediction bias and improve the synthesis stability. To validate the effectiveness of the proposed approach, extensive numerical simulation studies and a real-world healthcare case study were applied and the results demonstrated that the proposed method is very promising.

Add to Chrome

Add to Chrome Add to Firefox

Add to Firefox Add to Edge

Add to Edge