Yuanyuan Ding

RICO: Regularizing the Unobservable for Indoor Compositional Reconstruction

Mar 15, 2023

Abstract:Recently, neural implicit surfaces have become popular for multi-view reconstruction. To facilitate practical applications like scene editing and manipulation, some works extend the framework with semantic masks input for the object-compositional reconstruction rather than the holistic perspective. Though achieving plausible disentanglement, the performance drops significantly when processing the indoor scenes where objects are usually partially observed. We propose RICO to address this by regularizing the unobservable regions for indoor compositional reconstruction. Our key idea is to first regularize the smoothness of the occluded background, which then in turn guides the foreground object reconstruction in unobservable regions based on the object-background relationship. Particularly, we regularize the geometry smoothness of occluded background patches. With the improved background surface, the signed distance function and the reversedly rendered depth of objects can be optimized to bound them within the background range. Extensive experiments show our method outperforms other methods on synthetic and real-world indoor scenes and prove the effectiveness of proposed regularizations.

Cognitive Visual Inspection Service for LCD Manufacturing Industry

Jan 11, 2021

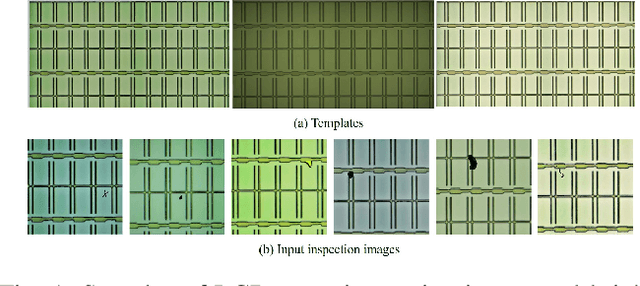

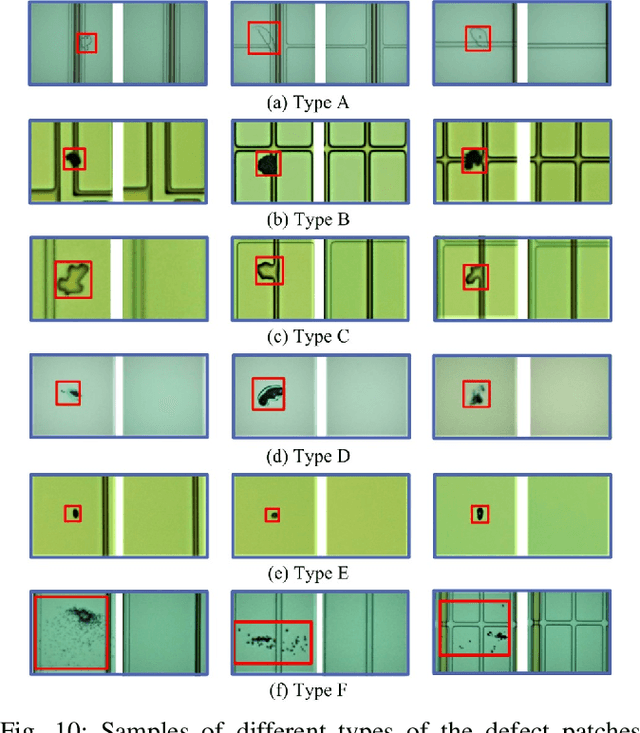

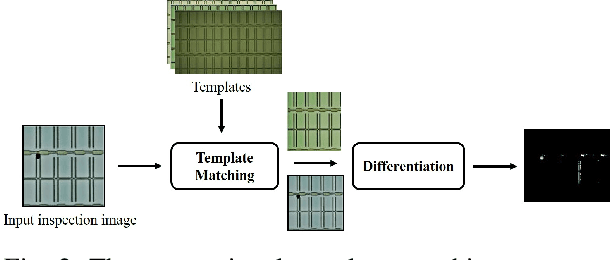

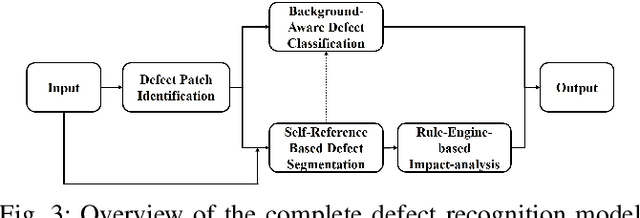

Abstract:With the rapid growth of display devices, quality inspection via machine vision technology has become increasingly important for flat-panel displays (FPD) industry. This paper discloses a novel visual inspection system for liquid crystal display (LCD), which is currently a dominant type in the FPD industry. The system is based on two cornerstones: robust/high-performance defect recognition model and cognitive visual inspection service architecture. A hybrid application of conventional computer vision technique and the latest deep convolutional neural network (DCNN) leads to an integrated defect detection, classfication and impact evaluation model that can be economically trained with only image-level class annotations to achieve a high inspection accuracy. In addition, the properly trained model is robust to the variation of the image qulity, significantly alleviating the dependency between the model prediction performance and the image aquisition environment. This in turn justifies the decoupling of the defect recognition functions from the front-end device to the back-end serivce, motivating the design and realization of the cognitive visual inspection service architecture. Empirical case study is performed on a large-scale real-world LCD dataset from a manufacturing line with different layers and products, which shows the promising utility of our system, which has been deployed in a real-world LCD manufacturing line from a major player in the world.

Add to Chrome

Add to Chrome Add to Firefox

Add to Firefox Add to Edge

Add to Edge