Tomáš Rybecký

Human Intention Recognition for Human Aware Planning in Integrated Warehouse Systems

May 22, 2020

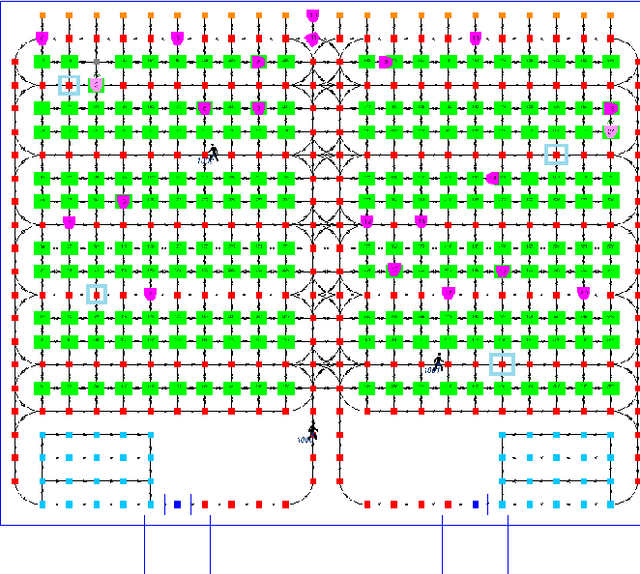

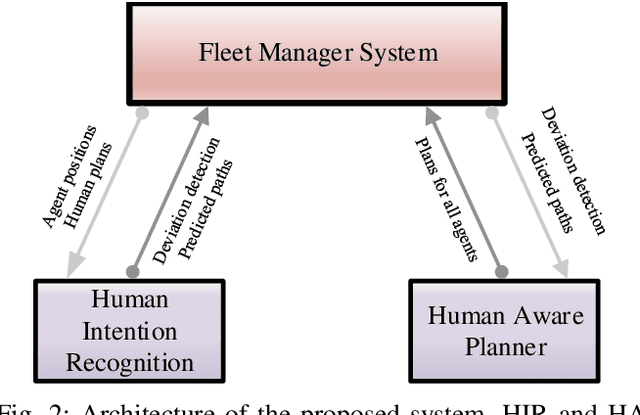

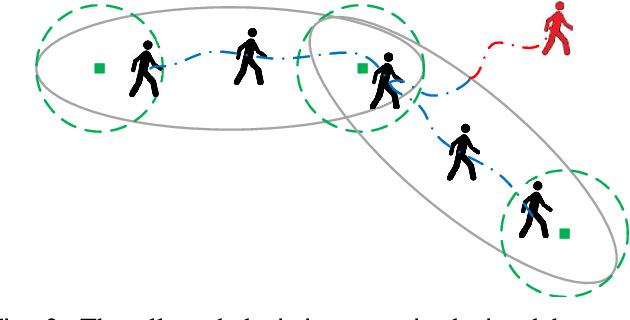

Abstract:With the substantial growth of logistics businesses the need for larger and more automated warehouses increases, thus giving rise to fully robotized shop-floors with mobile robots in charge of transporting and distributing goods. However, even in fully automatized warehouse systems the need for human intervention frequently arises, whether because of maintenance or because of fulfilling specific orders, thus bringing mobile robots and humans ever closer in an integrated warehouse environment. In order to ensure smooth and efficient operation of such a warehouse, paths of both robots and humans need to be carefully planned; however, due to the possibility of humans deviating from the assigned path, this becomes an even more challenging task. Given that, the supervising system should be able to recognize human intentions and its alternative paths in real-time. In this paper, we propose a framework for human deviation detection and intention recognition which outputs the most probable paths of the humans workers and the planner that acts accordingly by replanning for robots to move out of the human's path. Experimental results demonstrate that the proposed framework increases total number of deliveries, especially human deliveries, and reduces human-robot encounters.

Context-Aware Route Planning for Automated Warehouses

Jan 22, 2019

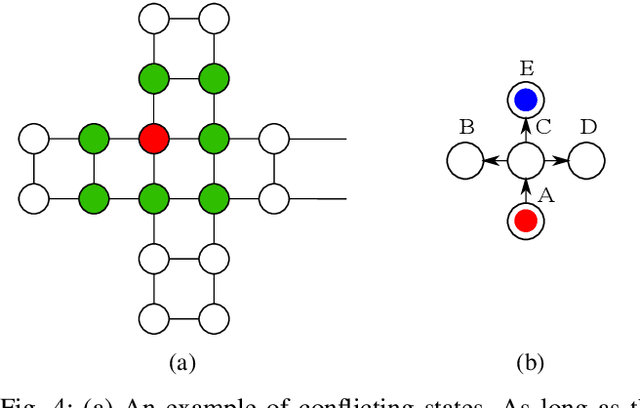

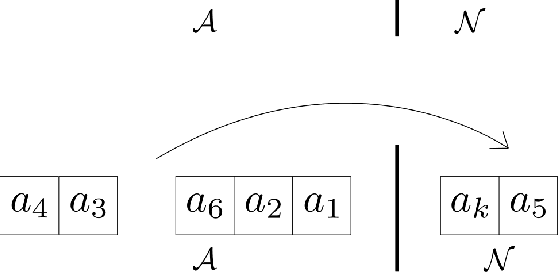

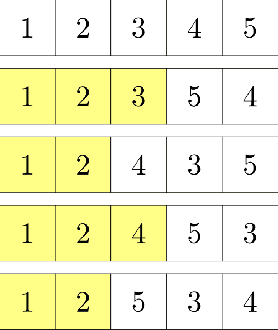

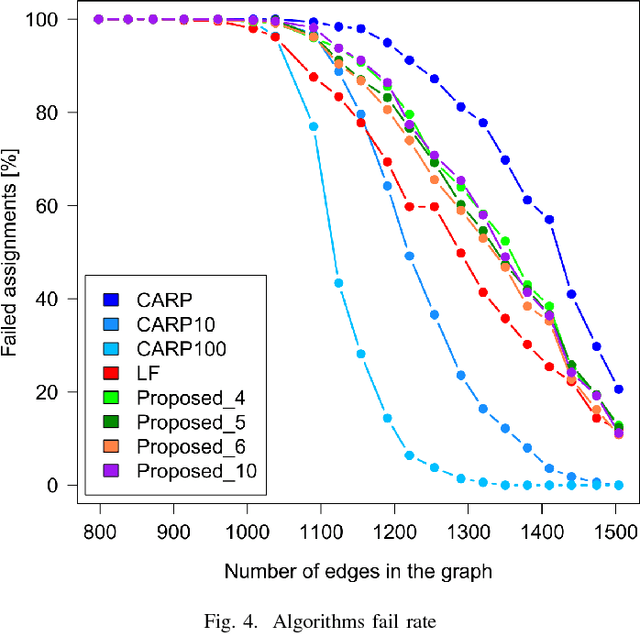

Abstract:In order to ensure efficient flow of goods in an automated warehouse and to guarantee its continuous distribution to/from picking stations in an effective way, decisions about which goods will be delivered to which particular picking station by which robot and by which path and in which time have to be made based on the current state of the warehouse. This task involves solution of two suproblems: (1) task allocation in which an assignment of robots to goods they have to deliver at a particular time is found and (2) planning of collision-free trajectories for particular robots (given their actual and goal positions). The trajectory planning problem is addressed in this paper taking into account specifics of automated warehouses. First, assignments of all robots are not known in advance, they are instead presented to the algorithm gradually one by one. Moreover, we do not optimize a makespan, but a throughput - the sum of individual robot plan costs. We introduce a novel approach to this problem which is based on the context-aware route planning algorithm [1]. The performed experimental results show that the proposed approach has a lower fail rate and produces results of higher quality than the original algorithm. This is redeemed by higher computational complexity which is nevertheless low enough for real-time planning.

Add to Chrome

Add to Chrome Add to Firefox

Add to Firefox Add to Edge

Add to Edge