Sergio Aguilera Marinovic

Honda Research Institute USA

Diffusing Trajectory Optimization Problems for Recovery During Multi-Finger Manipulation

Oct 08, 2025Abstract:Multi-fingered hands are emerging as powerful platforms for performing fine manipulation tasks, including tool use. However, environmental perturbations or execution errors can impede task performance, motivating the use of recovery behaviors that enable normal task execution to resume. In this work, we take advantage of recent advances in diffusion models to construct a framework that autonomously identifies when recovery is necessary and optimizes contact-rich trajectories to recover. We use a diffusion model trained on the task to estimate when states are not conducive to task execution, framed as an out-of-distribution detection problem. We then use diffusion sampling to project these states in-distribution and use trajectory optimization to plan contact-rich recovery trajectories. We also propose a novel diffusion-based approach that distills this process to efficiently diffuse the full parameterization, including constraints, goal state, and initialization, of the recovery trajectory optimization problem, saving time during online execution. We compare our method to a reinforcement learning baseline and other methods that do not explicitly plan contact interactions, including on a hardware screwdriver-turning task where we show that recovering using our method improves task performance by 96% and that ours is the only method evaluated that can attempt recovery without causing catastrophic task failure. Videos can be found at https://dtourrecovery.github.io/.

GeoDEx: A Unified Geometric Framework for Tactile Dexterous and Extrinsic Manipulation under Force Uncertainty

May 01, 2025Abstract:Sense of touch that allows robots to detect contact and measure interaction forces enables them to perform challenging tasks such as grasping fragile objects or using tools. Tactile sensors in theory can equip the robots with such capabilities. However, accuracy of the measured forces is not on a par with those of the force sensors due to the potential calibration challenges and noise. This has limited the values these sensors can offer in manipulation applications that require force control. In this paper, we introduce GeoDEx, a unified estimation, planning, and control framework using geometric primitives such as plane, cone and ellipsoid, which enables dexterous as well as extrinsic manipulation in the presence of uncertain force readings. Through various experimental results, we show that while relying on direct inaccurate and noisy force readings from tactile sensors results in unstable or failed manipulation, our method enables successful grasping and extrinsic manipulation of different objects. Additionally, compared to directly running optimization using SOCP (Second Order Cone Programming), planning and force estimation using our framework achieves a 14x speed-up.

Diffusion-Informed Probabilistic Contact Search for Multi-Finger Manipulation

Oct 01, 2024

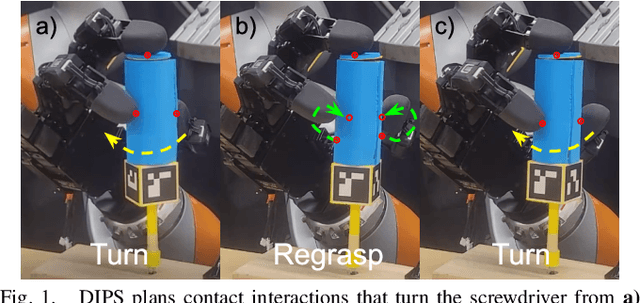

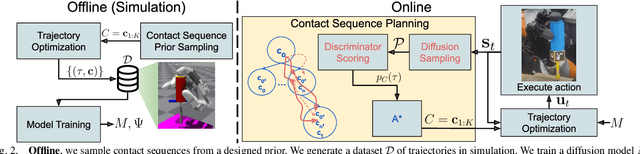

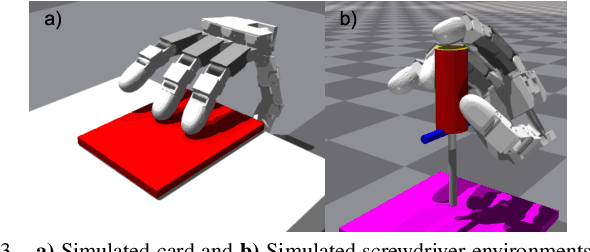

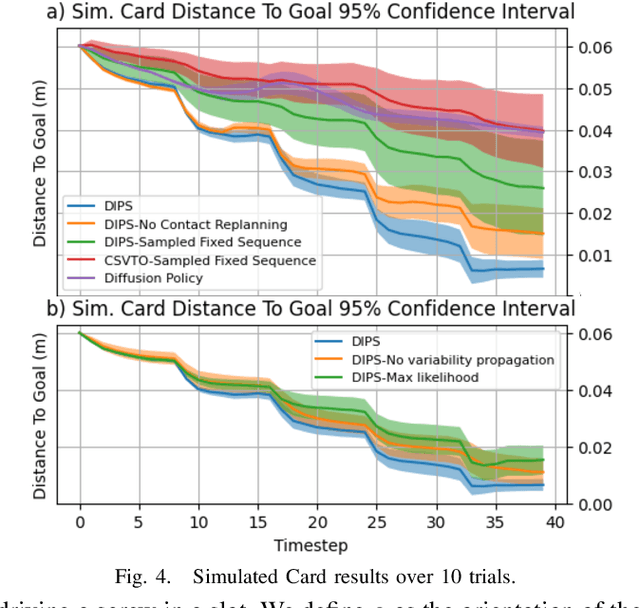

Abstract:Planning contact-rich interactions for multi-finger manipulation is challenging due to the high-dimensionality and hybrid nature of dynamics. Recent advances in data-driven methods have shown promise, but are sensitive to the quality of training data. Combining learning with classical methods like trajectory optimization and search adds additional structure to the problem and domain knowledge in the form of constraints, which can lead to outperforming the data on which models are trained. We present Diffusion-Informed Probabilistic Contact Search (DIPS), which uses an A* search to plan a sequence of contact modes informed by a diffusion model. We train the diffusion model on a dataset of demonstrations consisting of contact modes and trajectories generated by a trajectory optimizer given those modes. In addition, we use a particle filter-inspired method to reason about variability in diffusion sampling arising from model error, estimating likelihoods of trajectories using a learned discriminator. We show that our method outperforms ablations that do not reason about variability and can plan contact sequences that outperform those found in training data across multiple tasks. We evaluate on simulated tabletop card sliding and screwdriver turning tasks, as well as the screwdriver task in hardware to show that our combined learning and planning approach transfers to the real world.

Multi-finger Manipulation via Trajectory Optimization with Differentiable Rolling and Geometric Constraints

Aug 23, 2024Abstract:Parameterizing finger rolling and finger-object contacts in a differentiable manner is important for formulating dexterous manipulation as a trajectory optimization problem. In contrast to previous methods which often assume simplified geometries of the robot and object or do not explicitly model finger rolling, we propose a method to further extend the capabilities of dexterous manipulation by accounting for non-trivial geometries of both the robot and the object. By integrating the object's Signed Distance Field (SDF) with a sampling method, our method estimates contact and rolling-related variables and includes those in a trajectory optimization framework. This formulation naturally allows for the emergence of finger-rolling behaviors, enabling the robot to locally adjust the contact points. Our method is tested in a peg alignment task and a screwdriver turning task, where it outperforms the baselines in terms of achieving desired object configurations and avoiding dropping the object. We also successfully apply our method to a real-world screwdriver turning task, demonstrating its robustness to the sim2real gap.

Add to Chrome

Add to Chrome Add to Firefox

Add to Firefox Add to Edge

Add to Edge