Mohatashem Reyaz Makhdoomi

Evaluation of Position and Velocity Based Forward Dynamics Compliance Control (FDCC) for Robotic Interactions in Position Controlled Robots

Oct 24, 2022Abstract:In robotic manipulation, end-effector compliance is an essential precondition for performing contact-rich tasks, such as machining, assembly, and human-robot interaction. Most robotic arms are position-controlled stiff systems at a hardware level. Thus, adding compliance becomes essential. Compliance in those systems has been recently achieved using Forward dynamics compliance control (FDCC), which, owing to its virtual forward dynamics model, can be implemented on both position and velocity-controlled robots. This paper evaluates the choice of control interface (and hence the control domain), which, although considered trivial, is essential due to differences in their characteristics. In some cases, the choice is restricted to the available hardware interface. However, given the option to choose, the velocity-based control interface makes a better candidate for compliance control because of smoother compliant behaviour, reduced interaction forces, and work done. To prove these points, in this paper FDCC is evaluated on the UR10e six-DOF manipulator with velocity and position control modes. The evaluation is based on force-control benchmarking metrics using 3D-printed artefacts. Real experiments favour the choice of velocity control over position control.

Emulating On-Orbit Interactions Using Forward Dynamics Based Cartesian Motion

Sep 30, 2022

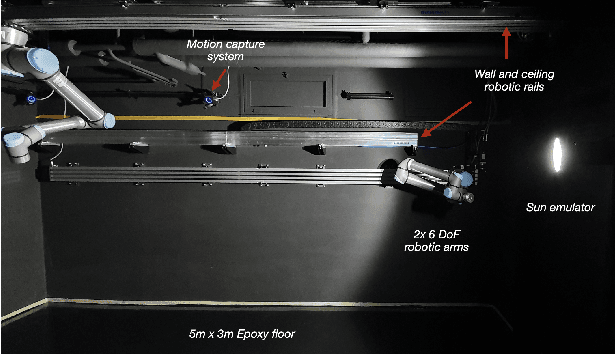

Abstract:The paper presents a novel Hardware-In-the-Loop (HIL) emulation framework of on-orbit interactions using on-ground robotic manipulators. It combines Virtual Forward Dynamic Model (VFDM) for Cartesian motion control of robotic manipulators with an Orbital Dynamics Simulator (ODS) based on the Clohessy Wiltshire (CW) Model. VFDM-based Inverse Kinematics (IK) solver is known to have better motion tracking, path accuracy, and solver convergency than traditional IK solvers. Therefore it provides a stable Cartesian motion for manipulator-based HIL on-orbit emulations. The framework is tested on a ROS-based robotics testbed to emulate two scenarios: free-floating satellite motion and free-floating interaction (collision). Mock-ups of two satellites are mounted at the robots' end-effectors. Forces acting on the mock-ups are measured through an in-built F/T sensor on each robotic arm. During the tests, the relative motion of the mock-ups is expressed with respect to a moving observer rotating at a fixed angular velocity in a circular orbit rather than their motion in the inertial frame. The ODS incorporates the force and torque values on the fly and delivers the corresponding satellite motions to the virtual forward dynamics model as online trajectories. Results are comparable to other free-floating HIL emulators. Fidelity between the simulated motion and robot-mounted mock-up motion is confirmed.

Lessons from a Space Lab -- An Image Acquisition Perspective

Aug 18, 2022

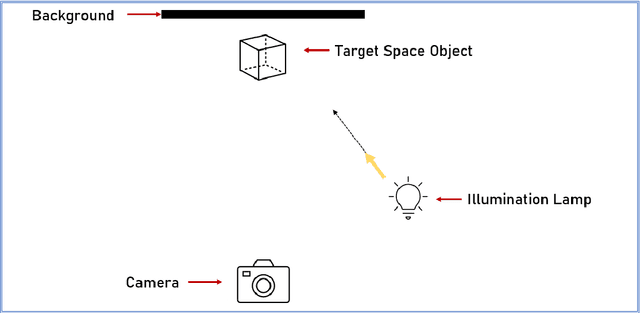

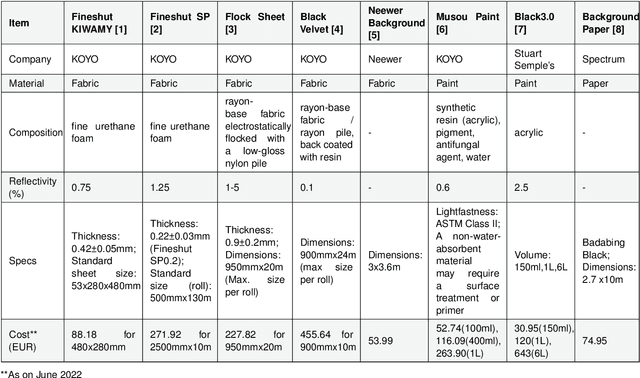

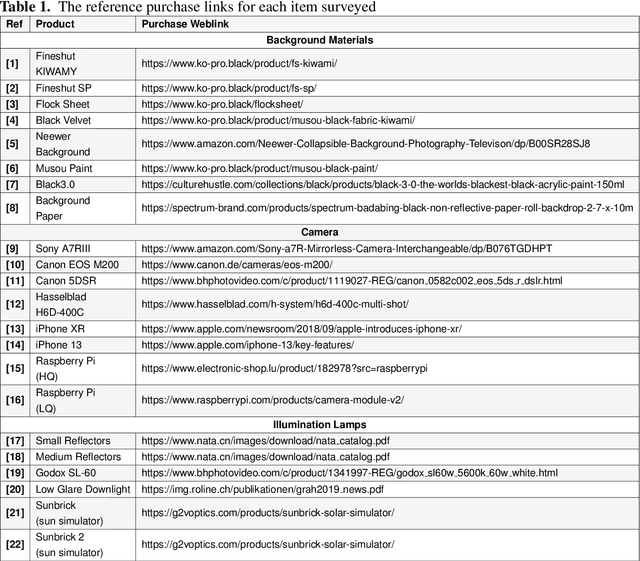

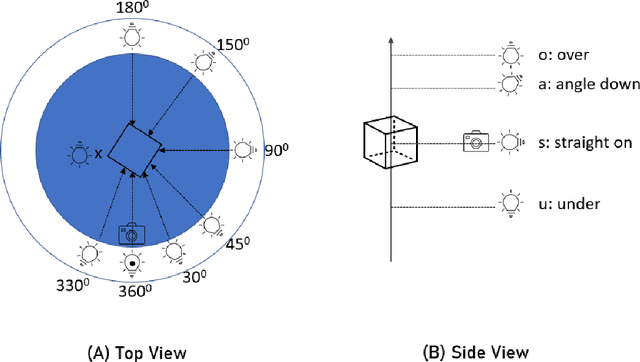

Abstract:The use of Deep Learning (DL) algorithms has improved the performance of vision-based space applications in recent years. However, generating large amounts of annotated data for training these DL algorithms has proven challenging. While synthetically generated images can be used, the DL models trained on synthetic data are often susceptible to performance degradation, when tested in real-world environments. In this context, the Interdisciplinary Center of Security, Reliability and Trust (SnT) at the University of Luxembourg has developed the 'SnT Zero-G Lab', for training and validating vision-based space algorithms in conditions emulating real-world space environments. An important aspect of the SnT Zero-G Lab development was the equipment selection. From the lessons learned during the lab development, this article presents a systematic approach combining market survey and experimental analyses for equipment selection. In particular, the article focus on the image acquisition equipment in a space lab: background materials, cameras and illumination lamps. The results from the experiment analyses show that the market survey complimented by experimental analyses is required for effective equipment selection in a space lab development project.

Add to Chrome

Add to Chrome Add to Firefox

Add to Firefox Add to Edge

Add to Edge