Meredith L. Anderson

Safe Autonomous Environmental Contact for Soft Robots using Control Barrier Functions

Apr 20, 2025Abstract:Robots built from soft materials will inherently apply lower environmental forces than their rigid counterparts, and therefore may be more suitable in sensitive settings with unintended contact. However, these robots' applied forces result from both their design and their control system in closed-loop, and therefore, ensuring bounds on these forces requires controller synthesis for safety as well. This article introduces the first feedback controller for a soft manipulator that formally meets a safety specification with respect to environmental contact. In our proof-of-concept setting, the robot's environment has known geometry and is deformable with a known elastic modulus. Our approach maps a bound on applied forces to a safe set of positions of the robot's tip via predicted deformations of the environment. Then, a quadratic program with Control Barrier Functions in its constraints is used to supervise a nominal feedback signal, verifiably maintaining the robot's tip within this safe set. Hardware experiments on a multi-segment soft pneumatic robot demonstrate that the proposed framework successfully constrains its environmental contact forces. This framework represents a fundamental shift in perspective on control and safety for soft robots, defining and implementing a formally verifiable logic specification on their pose and contact forces.

Real-Time Trajectory Generation for Soft Robot Manipulators Using Differential Flatness

Dec 11, 2024

Abstract:Soft robots have the potential to interact with sensitive environments and perform complex tasks effectively. However, motion plans and trajectories for soft manipulators are challenging to calculate due to their deformable nature and nonlinear dynamics. This article introduces a fast real-time trajectory generation approach for soft robot manipulators, which creates dynamically-feasible motions for arbitrary kinematically-feasible paths of the robot's end effector. Our insight is that piecewise constant curvature (PCC) dynamics models of soft robots can be differentially flat, therefore control inputs can be calculated algebraically rather than through a nonlinear differential equation. We prove this flatness under certain conditions, with the curvatures of the robot as the flat outputs. Our two-step trajectory generation approach uses an inverse kinematics procedure to calculate a motion plan of robot curvatures per end-effector position, then, our flatness diffeomorphism generates corresponding control inputs that respect velocity. We validate our approach through simulations of our representative soft robot manipulator along three different trajectories, demonstrating a margin of 23x faster than real-time at a frequency of 100 Hz. This approach could allow fast verifiable replanning of soft robots' motions in safety-critical physical environments, crucial for deployment in the real world.

Self-Sensing for Proprioception and Contact Detection in Soft Robots Using Shape Memory Alloy Artificial Muscles

Sep 25, 2024

Abstract:Estimating a soft robot's pose and applied forces, also called proprioception, is crucial for safe interaction of the robot with its environment. However, most solutions for soft robot proprioception use dedicated sensors, particularly for external forces, which introduce design trade-offs, rigidity, and risk of failure. This work presents an approach for pose estimation and contact detection for soft robots actuated by shape memory alloy (SMA) artificial muscles, using no dedicated force sensors. Our framework uses the unique material properties of SMAs to self-sense their internal stress, via offboard measurements of their electrical resistance and in-situ temperature readings, in an existing fully-soft limb design. We demonstrate that a simple polynomial regression model on these measurements is sufficient to predict the robot's pose, under no-contact conditions. Then, we show that if an additional measurement of the true pose is available (e.g. from an already-in-place bending sensor), it is possible to predict a binary contact/no-contact using multiple combinations of self-sensing signals. Our hardware tests verify our hypothesis via a contact detection test with a human operator. This proof-of-concept validates that self-sensing signals in soft SMA-actuated soft robots can be used for proprioception and contact detection, and suggests a direction for integrating proprioception into soft robots without design compromises. Future work could employ machine learning for enhanced accuracy.

Maximizing Consistent Force Output for Shape Memory Alloy Artificial Muscles in Soft Robots

Feb 09, 2024

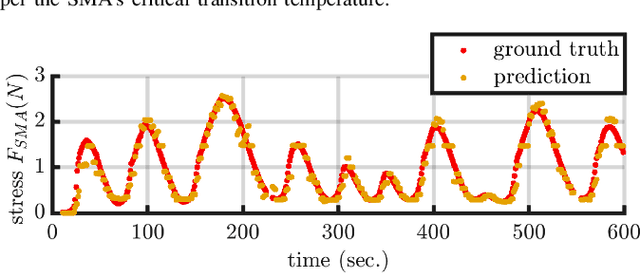

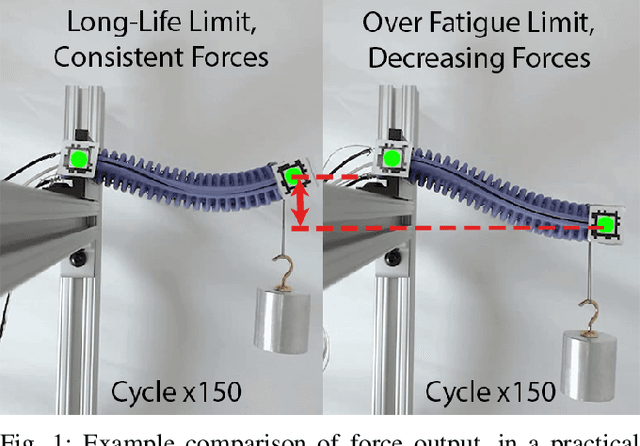

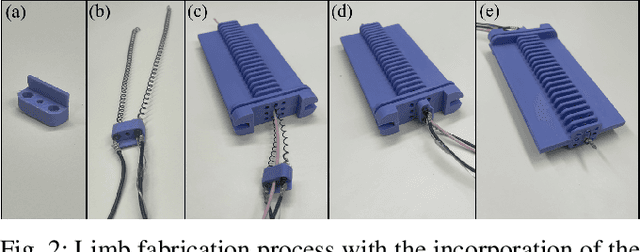

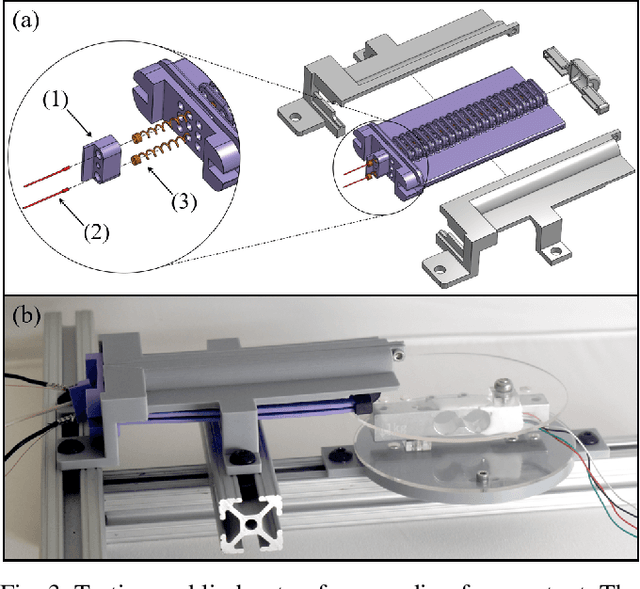

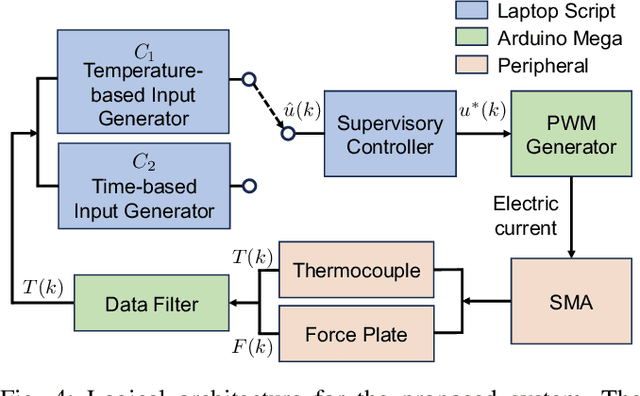

Abstract:Soft robots have immense potential given their inherent safety and adaptability, but challenges in soft actuator forces and design constraints have limited scaling up soft robots to larger sizes. Electrothermal shape memory alloy (SMA) artificial muscles have the potential to create these large forces and high displacements, but consistently using these muscles under a well-defined model, in-situ in a soft robot, remains an open challenge. This article provides a system for maintaining the highest-possible consistent SMA forces, over long lifetimes, by combining a fatigue testing protocol with a supervisory control system for the muscles' internal temperature state. We propose a design of a soft limb with swap-able SMA muscles, and deploy the limb in a blocked-force test to quantify the relationship between the measured maximum force at different temperatures over different lifetimes. Then, by applying an invariance-based control system to maintain temperatures under our long-life limit, we demonstrate consistent high forces in a practical task over hundreds of cycles. The method we developed allows for practical implementation of SMAs in soft robots through characterizing and controlling their behavior in-situ, and provides a method to impose limits that maximize their consistent, repeatable behavior.

Safe Balancing Control of a Soft Legged Robot

Sep 27, 2022

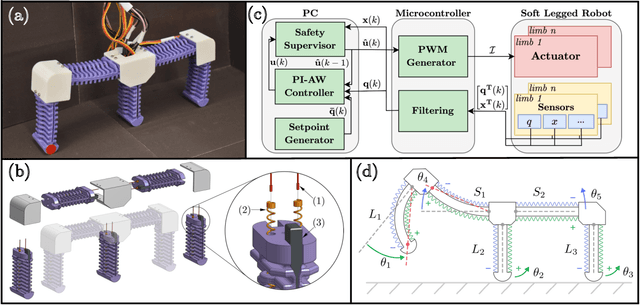

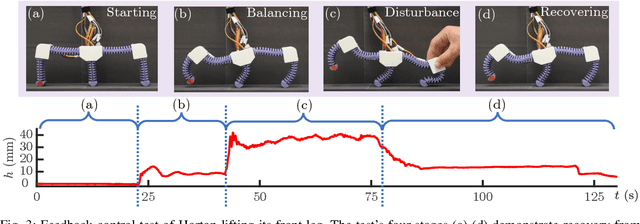

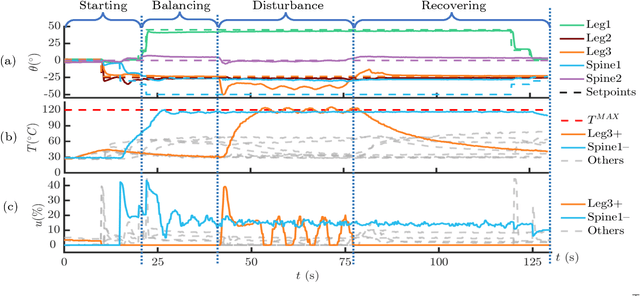

Abstract:Legged robots constructed from soft materials are commonly claimed to demonstrate safer, more robust environmental interactions than their rigid counterparts. However, this motivating feature of soft robots requires more rigorous development for comparison to rigid locomotion. This article presents a soft legged robot platform, Horton, and a feedback control system with safety guarantees on some aspects of its operation. The robot is constructed using a series of soft limbs, actuated by thermal shape memory alloy (SMA) wire muscles, with sensors for its position and its actuator temperatures. A supervisory control scheme maintains safe actuator states during the operation of a separate controller for the robot's pose. Experiments demonstrate that Horton can lift its leg and maintain a balancing stance, a precursor to locomotion. The supervisor is verified in hardware via a human interaction test during balancing, keeping all SMA muscles below a temperature threshold. This work represents the first demonstration of a safety-verified feedback system on any soft legged robot.

Add to Chrome

Add to Chrome Add to Firefox

Add to Firefox Add to Edge

Add to Edge