Maximizing Consistent Force Output for Shape Memory Alloy Artificial Muscles in Soft Robots

Paper and Code

Feb 09, 2024

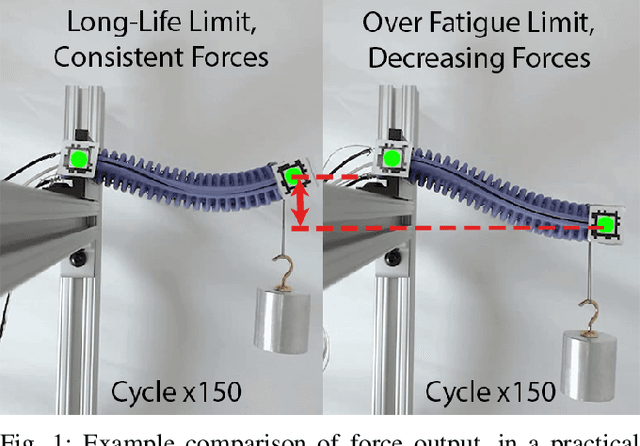

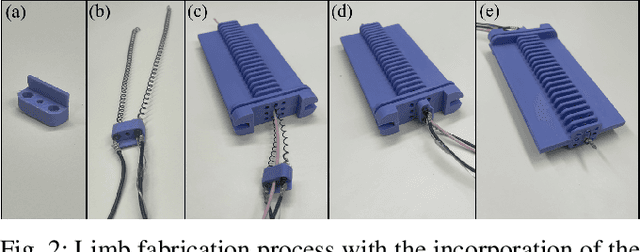

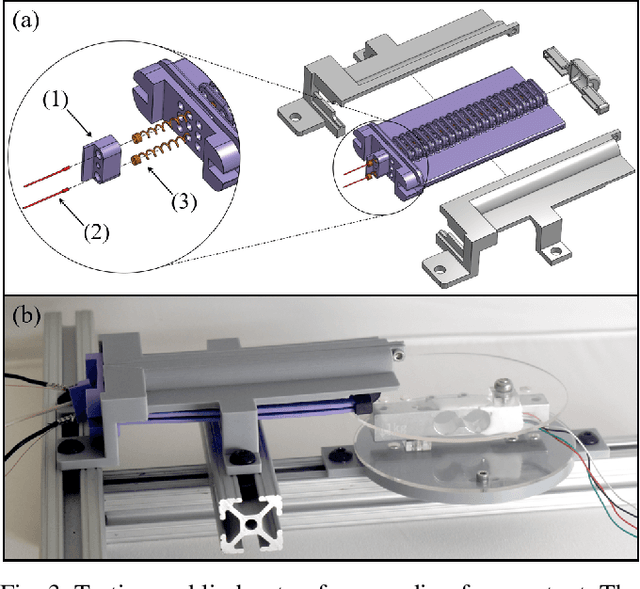

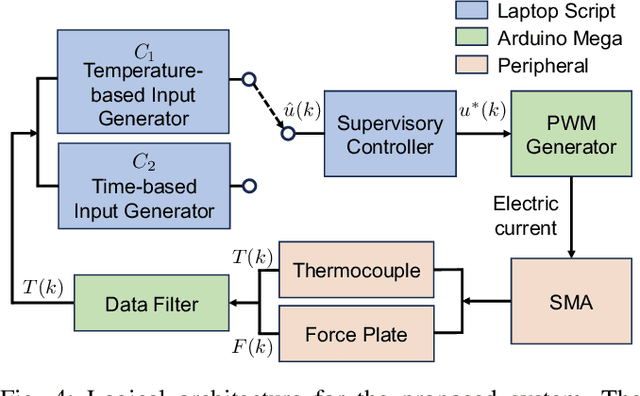

Soft robots have immense potential given their inherent safety and adaptability, but challenges in soft actuator forces and design constraints have limited scaling up soft robots to larger sizes. Electrothermal shape memory alloy (SMA) artificial muscles have the potential to create these large forces and high displacements, but consistently using these muscles under a well-defined model, in-situ in a soft robot, remains an open challenge. This article provides a system for maintaining the highest-possible consistent SMA forces, over long lifetimes, by combining a fatigue testing protocol with a supervisory control system for the muscles' internal temperature state. We propose a design of a soft limb with swap-able SMA muscles, and deploy the limb in a blocked-force test to quantify the relationship between the measured maximum force at different temperatures over different lifetimes. Then, by applying an invariance-based control system to maintain temperatures under our long-life limit, we demonstrate consistent high forces in a practical task over hundreds of cycles. The method we developed allows for practical implementation of SMAs in soft robots through characterizing and controlling their behavior in-situ, and provides a method to impose limits that maximize their consistent, repeatable behavior.

Add to Chrome

Add to Chrome Add to Firefox

Add to Firefox Add to Edge

Add to Edge