Kartik Suryavanshi

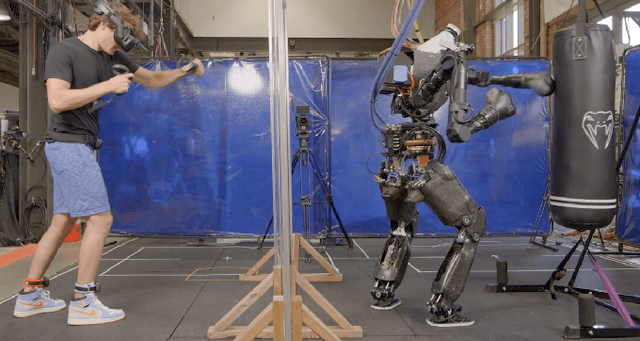

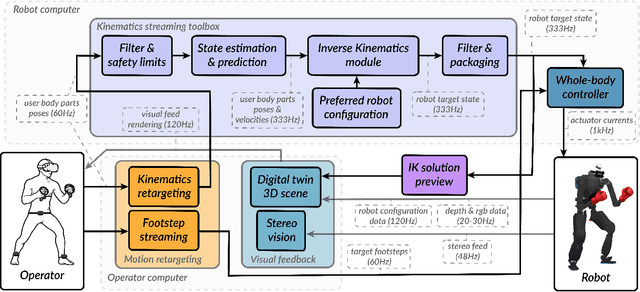

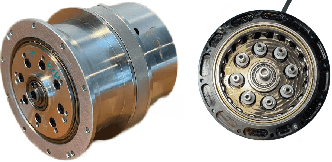

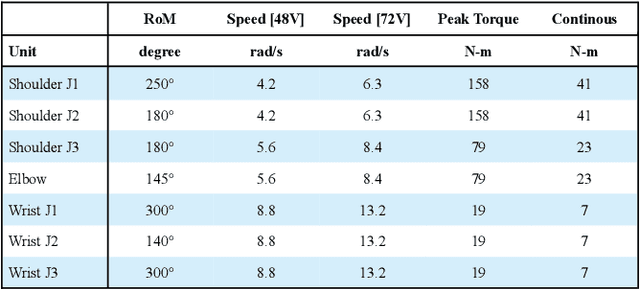

High-Speed and Impact Resilient Teleoperation of Humanoid Robots

Sep 06, 2024

Abstract:Teleoperation of humanoid robots has long been a challenging domain, necessitating advances in both hardware and software to achieve seamless and intuitive control. This paper presents an integrated solution based on several elements: calibration-free motion capture and retargeting, low-latency fast whole-body kinematics streaming toolbox and high-bandwidth cycloidal actuators. Our motion retargeting approach stands out for its simplicity, requiring only 7 IMUs to generate full-body references for the robot. The kinematics streaming toolbox, ensures real-time, responsive control of the robot's movements, significantly reducing latency and enhancing operational efficiency. Additionally, the use of cycloidal actuators makes it possible to withstand high speeds and impacts with the environment. Together, these approaches contribute to a teleoperation framework that offers unprecedented performance. Experimental results on the humanoid robot Nadia demonstrate the effectiveness of the integrated system.

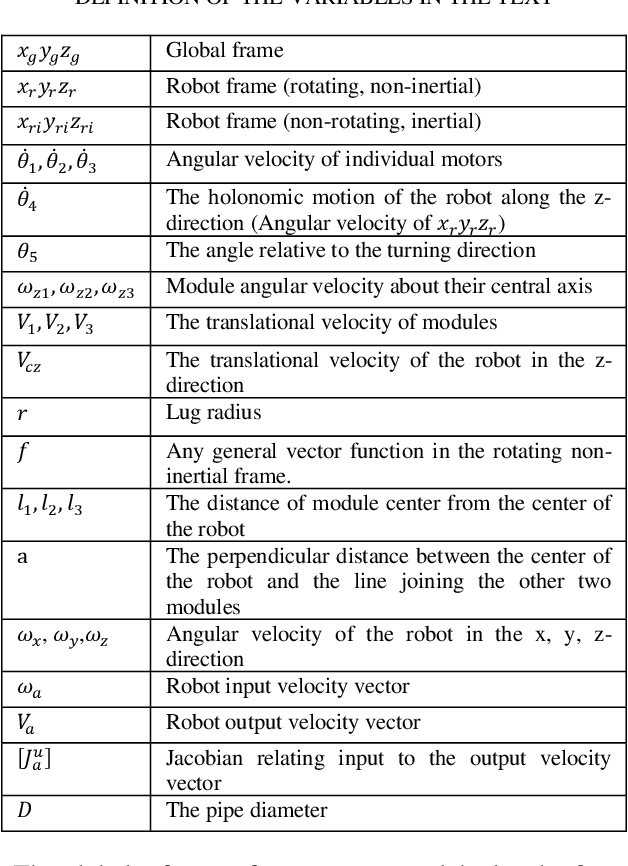

Omnidirectional Three Module Robot Design and Simulation

Feb 19, 2020

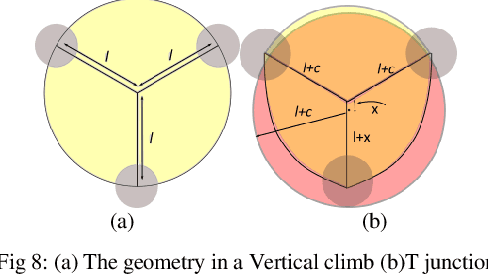

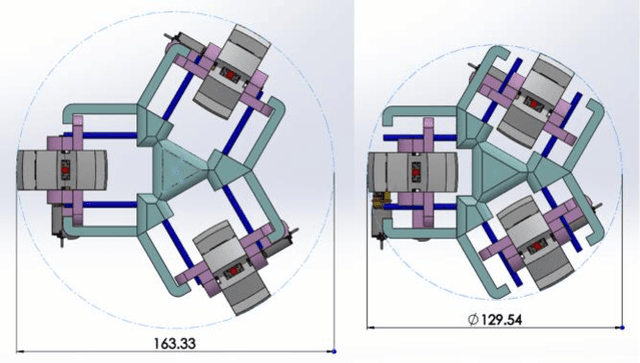

Abstract:This paper introduces the Omnidirectional Tractable Three Module Robot for traversing inside complex pipe networks. The robot consists of three omnidirectional modules fixed 120{\deg} apart circumferentially which can rotate about their axis allowing holonomic motion of the robot. Holonomic motion enables the robot to overcome motion singularity when negotiating T-junctions and further allows the robot to arrive in a preferred orientation while taking turns inside a pipe. The singularity region while negotiating T-junctions is analyzed to formulate the geometry of the region. The design and motion capabilities are validated by conducting simulations in MSC ADAMS on a simplified lumped-model of the robot.

Omnidirectional Tractable Three Module Robot

Sep 23, 2019

Abstract:This paper introduces the Omnidirectional Tractable Three Module Robot for traversing inside complex pipe networks. The robot consists of three omnidirectional modules fixed 120{\deg} apart circumferentially which can rotate about their own axis allowing holonomic motion of the robot. The holonomic motion enables the robot to overcome motion singularity when negotiating T-junctions and further allows the robot to arrive in a preferred orientation while taking turns inside a pipe. We have developed a closed-form kinematic model for the robot in the paper and propose the Motion Singularity Region that the robot needs to avoid while negotiating T-junction. The design and motion capabilities of the robot are demonstrated both by conducting simulations in MSC ADAMS on a simplified lumped-model of the robot and with experiments on its physical embodiment.

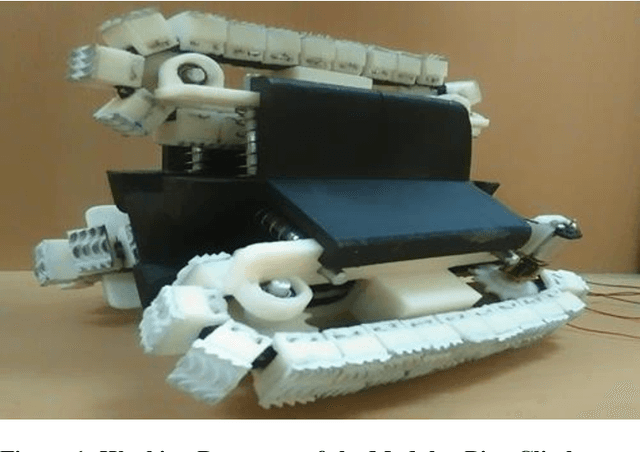

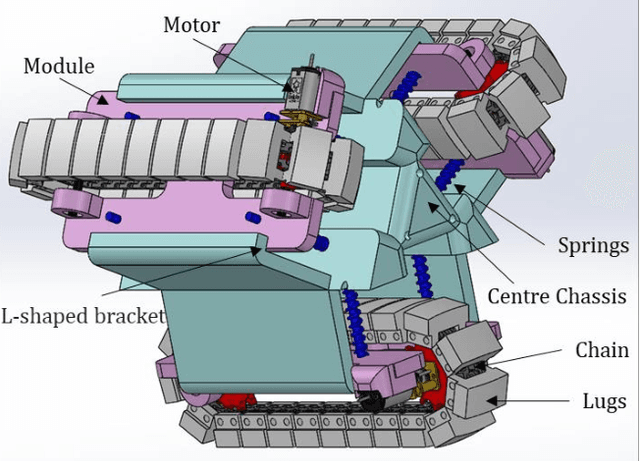

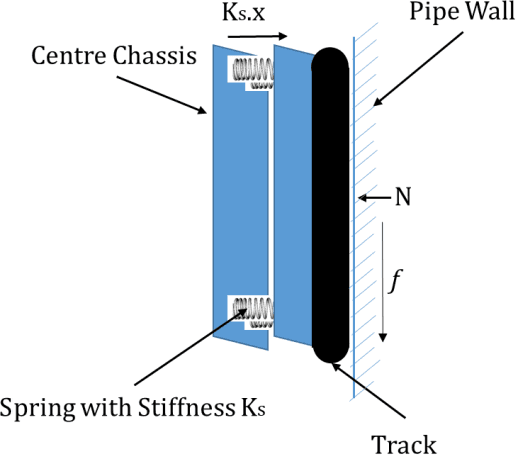

Modular Pipe Climber

Sep 23, 2019

Abstract:This paper discusses the design and implementation of the Modular Pipe Climber inside ASTM D1785 - 15e1 standard pipes [1]. The robot has three tracks which operate independently and are mounted on three modules which are oriented at 120{\deg} to each other. The tracks provide for greater surface traction compared to wheels [2]. The tracks are pushed onto the inner wall of the pipe by passive springs which help in maintaining the contact with the pipe during vertical climb and while turning in bends. The modules have the provision to compress asymmetrically, which helps the robot to take turns in bends in all directions. The motor torque required by the robot and the desired spring stiffness are calculated at quasistatic and static equilibriums when the pipe climber is in a vertical climb. The springs were further simulated and analyzed in ADAMS MSC. The prototype built based on these obtained values was experimented on, in complex pipe networks. Differential speed is employed when turning in bends to improve the efficiency and reduce the stresses experienced by the robot.

Add to Chrome

Add to Chrome Add to Firefox

Add to Firefox Add to Edge

Add to Edge