Joseph A. Libera

A framework for fully autonomous design of materials via multiobjective optimization and active learning: challenges and next steps

Apr 15, 2023Abstract:In order to deploy machine learning in a real-world self-driving laboratory where data acquisition is costly and there are multiple competing design criteria, systems need to be able to intelligently sample while balancing performance trade-offs and constraints. For these reasons, we present an active learning process based on multiobjective black-box optimization with continuously updated machine learning models. This workflow is built on open-source technologies for real-time data streaming and modular multiobjective optimization software development. We demonstrate a proof of concept for this workflow through the autonomous operation of a continuous-flow chemistry laboratory, which identifies ideal manufacturing conditions for the electrolyte 2,2,2-trifluoroethyl methyl carbonate.

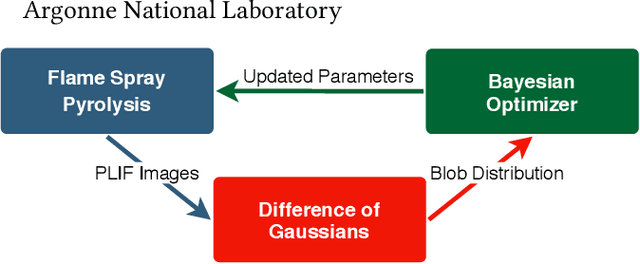

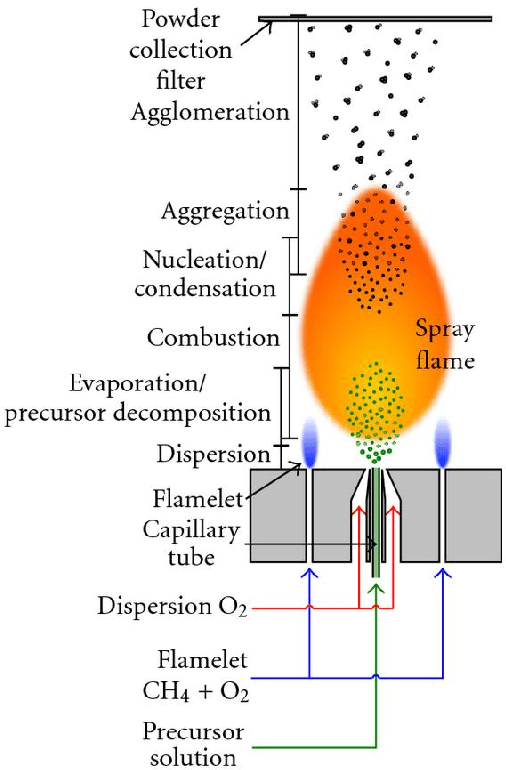

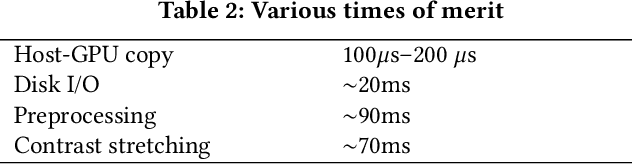

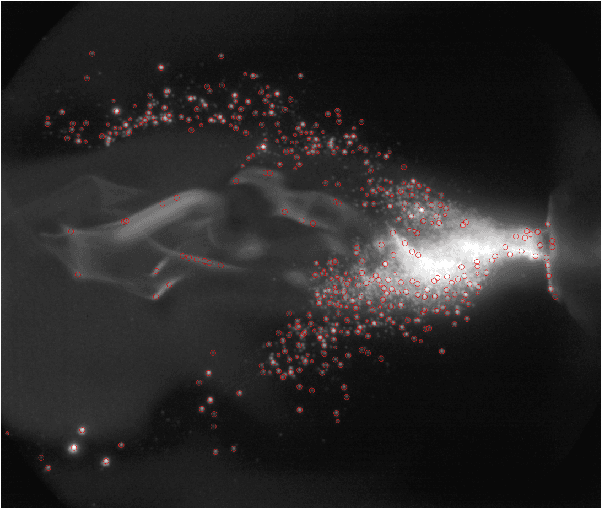

Towards Online Steering of Flame Spray Pyrolysis Nanoparticle Synthesis

Oct 16, 2020

Abstract:Flame Spray Pyrolysis (FSP) is a manufacturing technique to mass produce engineered nanoparticles for applications in catalysis, energy materials, composites, and more. FSP instruments are highly dependent on a number of adjustable parameters, including fuel injection rate, fuel-oxygen mixtures, and temperature, which can greatly affect the quality, quantity, and properties of the yielded nanoparticles. Optimizing FSP synthesis requires monitoring, analyzing, characterizing, and modifying experimental conditions.Here, we propose a hybrid CPU-GPU Difference of Gaussians (DoG)method for characterizing the volume distribution of unburnt solution, so as to enable near-real-time optimization and steering of FSP experiments. Comparisons against standard implementations show our method to be an order of magnitude more efficient. This surrogate signal can be deployed as a component of an online end-to-end pipeline that maximizes the synthesis yield.

Add to Chrome

Add to Chrome Add to Firefox

Add to Firefox Add to Edge

Add to Edge