Johannes Ringwald

Identification and validation of the dynamic model of a tendon-driven anthropomorphic finger

Aug 23, 2024

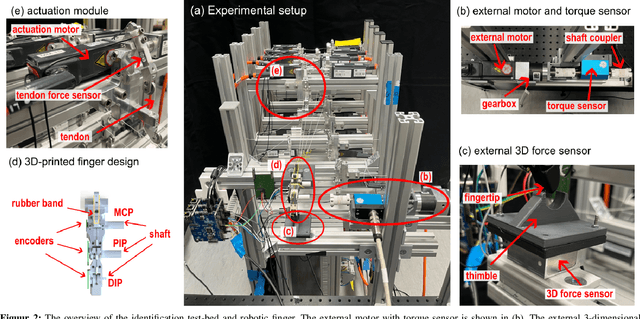

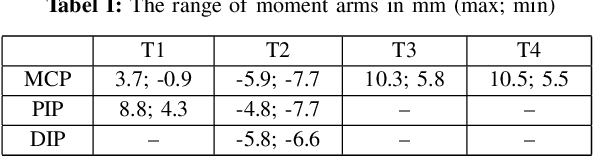

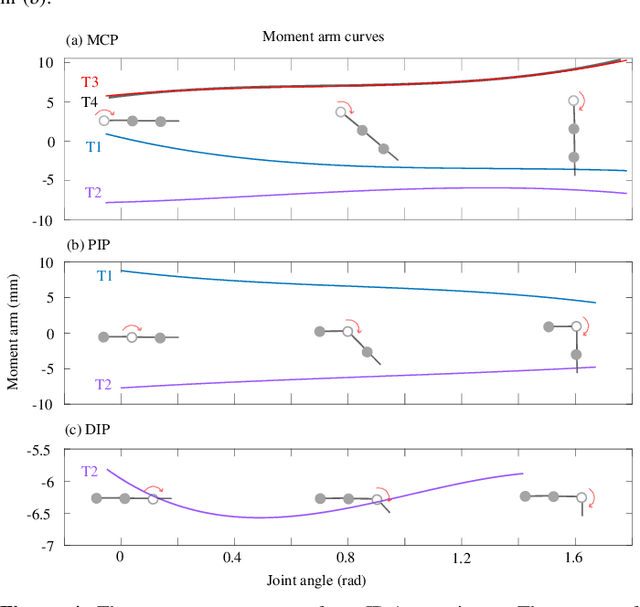

Abstract:This study addresses the absence of an identification framework to quantify a comprehensive dynamic model of human and anthropomorphic tendon-driven fingers, which is necessary to investigate the physiological properties of human fingers and improve the control of robotic hands. First, a generalized dynamic model was formulated, which takes into account the inherent properties of such a mechanical system. This includes rigid-body dynamics, coupling matrix, joint viscoelasticity, and tendon friction. Then, we propose a methodology comprising a series of experiments, for step-wise identification and validation of this dynamic model. Moreover, an experimental setup was designed and constructed that features actuation modules and peripheral sensors to facilitate the identification process. To verify the proposed methodology, a 3D-printed robotic finger based on the index finger design of the Dexmart hand was developed, and the proposed experiments were executed to identify and validate its dynamic model. This study could be extended to explore the identification of cadaver hands, aiming for a consistent dataset from a single cadaver specimen to improve the development of musculoskeletal hand models.

Towards Task-Specific Modular Gripper Fingers: Automatic Production of Fingertip Mechanics

Oct 18, 2022

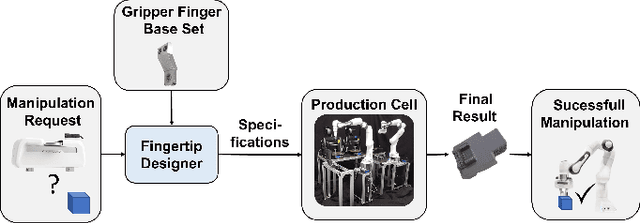

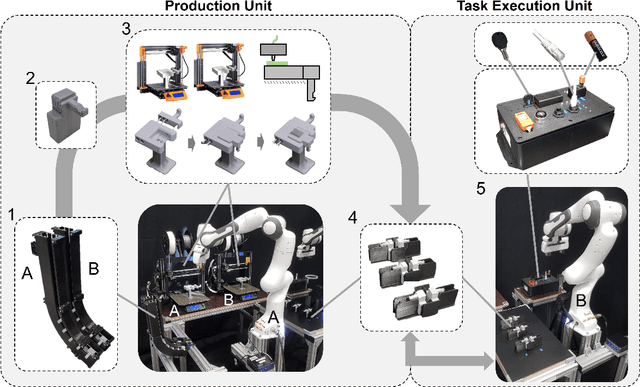

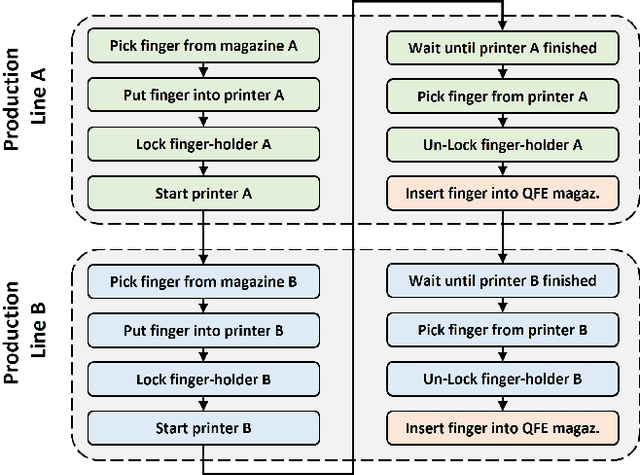

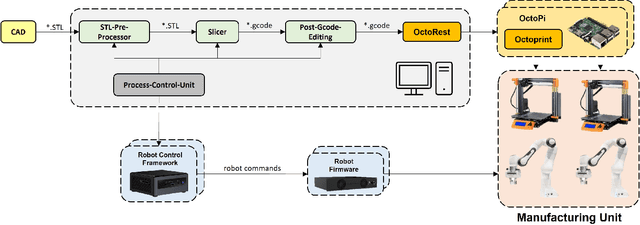

Abstract:The number of sequential tasks a single gripper can perform is significantly limited by its design. In many cases, changing the gripper fingers is required to successfully conduct multiple consecutive tasks. For this reason, several robotic tool change systems have been introduced that allow an automatic changing of the entire end-effector. However, many situations require only the modification or the change of the fingertip, making the exchange of the entire gripper uneconomic. In this paper, we introduce a paradigm for automatic task-specific fingertip production. The setup used in the proposed framework consists of a production and task execution unit, containing a robotic manipulator, and two 3D printers - autonomously producing the gripper fingers. It also consists of a second manipulator that uses a quick-exchange mechanism to pick up the printed fingertips and evaluates gripping performance. The setup is experimentally validated by conducting automatic production of three different fingertips and executing graspstability tests as well as multiple pick- and insertion tasks, with and without position offsets - using these fingertips. The proposed paradigm, indeed, goes beyond fingertip production and serves as a foundation for a fully automatic fingertip design, production and application pipeline - potentially improving manufacturing flexibility and representing a new production paradigm: tactile 3D manufacturing.

Add to Chrome

Add to Chrome Add to Firefox

Add to Firefox Add to Edge

Add to Edge