Jean-Sébastien Plante

Influence Vectors Control for Robots Using Cellular-like Binary Actuators

Jul 25, 2024

Abstract:Robots using cellular-like redundant binary actuators could outmatch electric-gearmotor robotic systems in terms of reliability, force-to-weight ratio and cost. This paper presents a robust fault tolerant control scheme that is designed to meet the control challenges encountered by such robots, i.e., discrete actuator inputs, complex system modeling and cross-coupling between actuators. In the proposed scheme, a desired vectorial system output, such as a position or a force, is commanded by recruiting actuators based on their influence vectors on the output. No analytical model of the system is needed; influence vectors are identified experimentally by sequentially activating each actuator. For position control tasks, the controller uses a probabilistic approach and a genetic algorithm to determine an optimal combination of actuators to recruit. For motion control tasks, the controller uses a sliding mode approach and independent recruiting decision for each actuator. Experimental results on a four degrees of freedom binary manipulator with twenty actuators confirm the method's effectiveness, and its ability to tolerate massive perturbations and numerous actuator failures.

Soft Two-degree-of-freedom Dielectric Elastomer Position Sensor Exhibiting Linear Behavior

May 27, 2024

Abstract:Soft robots could bring robotic systems to new horizons, by enabling safe human-machine interaction. For precise control, these soft structures require high level position feedback that is not easily achieved through conventional one-degree-of-freedom (DOF) sensing apparatus. In this paper, a soft two-DOF dielectric elastomer (DE) sensor is specifically designed to provide accurate position feedback for a soft polymer robotic manipulator. The technology is exemplified on a soft robot intended for MRI-guided prostate interventions. DEs are chosen for their major advantages of softness, high strains, low cost and embedded multiple-DOF sensing capability, providing excellent system integration. A geometrical model of the proposed DE sensor is developed and compared to experimental results in order to understand sensor mechanics. Using a differential measurement approach, a handmade prototype provided linear sensory behavior and 0.2 mm accuracy on two-DOF. This correlates to a 0.7\% error over the sensor's 30 mm x 30 mm planar range, demonstrating the outstanding potential of DE technology for accurate multi-DOF position sensing.

A Bimodal Hydrostatic Actuator for Robotic Legs with Compliant Fast Motion and High Lifting Force

Oct 11, 2022

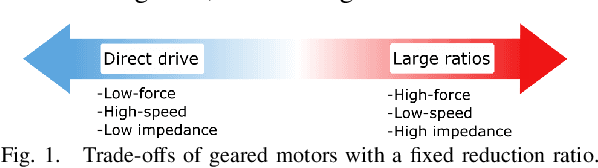

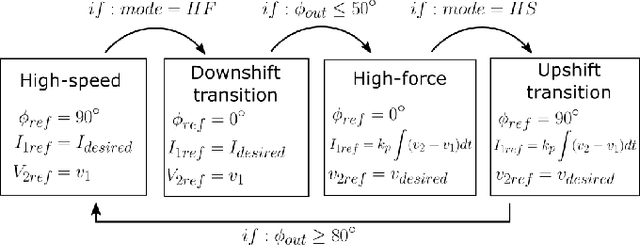

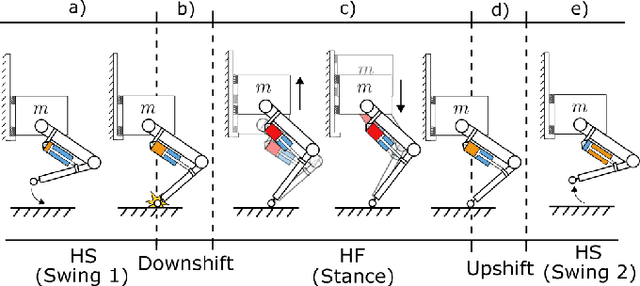

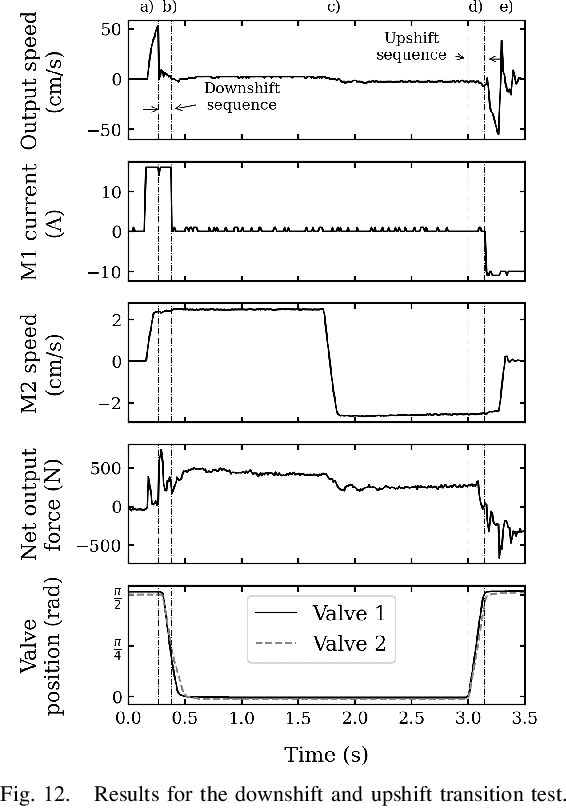

Abstract:Robotic legs have bimodal operations: swing phases when the leg needs to move quickly in the air (high-speed, low-force) and stance phases when the leg bears the weight of the system (low-speed, high-force). Sizing a traditional single-ratio actuation system for such extremum operations leads to oversized heavy electric motor and poor energy efficiency, which hinder the capability of legged systems that bear the mass of their actuators and energy source. This paper explores an actuation concept where a hydrostatic transmission is dynamically reconfigured using valves to suit the requirements of each phase of a robotic leg. An analysis of the mass-delay-flow trade-off for the switching valve is presented. Then, a custom actuation system is built and integrated on a robotic leg test bench to evaluate the concept. Experimental results show that 1) small motorized ball valves can make fast transitions between operating modes when designed for this task, 2) the proposed operating principle and control schemes allow for seamless transitions, even during an impact with the ground and 3) the actuator characteristics address the needs of a leg bimodal operation in terms of force, speed and compliance.

A Lightweight Force-Controllable Wearable Arm Based on Magnetorheological-Hydrostatic Actuators

Jun 27, 2022

Abstract:Supernumerary Robotic Limbs (SRLs) are wearable robots augmenting human capabilities by acting as a co-worker, reaching objects, support human arms, etc. However, existing SRLs lack the mechanical backdrivability and bandwidth required for tasks where the interaction forces must be controllable such as painting, manipulating fragile objects, etc. Being highly backdrivable with a high bandwidth while minimizing weight presents a major technological challenge imposed by the limited performances of conventional electromagnetic actuators. This paper studies the feasibility of using magnetorheological (MR) clutches coupled to a low-friction hydrostatic transmission to provide a highly capable, but yet lightweight, force-controllable SRL. A 2.7 kg 2-DOFs wearable robotic arm is designed and built. Shoulder and elbow joints are designed to deliver 39 and 25 Nm, with 115 and 180{\deg} of range of motion. Experimental studies conducted on a one-DOF test bench and validated analytically demonstrate a high force bandwidth (>25 Hz) and a good ability to control interaction forces even when interacting with an external impedance. Furthermore, three force-control approaches are studied and demonstrated experimentally: open-loop, closed-loop on force, and closed-loop on pressure. All three methods are shown to be effective. Overall, the proposed MR-Hydrostatic actuation system is well-suited for a lightweight SRL interacting with both human and environment that add unpredictable disturbances.

Performance Study of Low Inertia Magnetorheological Actuators for Kinesthetic Haptic Devices

Jun 01, 2022

Abstract:A challenge to high quality virtual reality (VR) simulations is the development of high-fidelity haptic devices that can render a wide range of impedances at both low and high frequencies. To this end, a thorough analytical and experimental assessment of the performance of magnetorheological (MR) actuators is performed and compared to electric motor (EM) actuation. A 2 degrees-of-freedom dynamic model of a kinesthetic haptic device is used to conduct the analytical study comparing the rendering area, rendering bandwidth, gearing and scaling of both technologies. Simulation predictions are corroborated by experimental validation over a wide range of operating conditions. Results show that, for a same output force, MR actuators can render a bandwidth over 52.9% higher than electric motors due to their low inertia. Unlike electric motors, the performance of MR actuators for use in haptic devices are not limited by their output inertia but by their viscous damping, which must be carefully addressed at the design stage.

Add to Chrome

Add to Chrome Add to Firefox

Add to Firefox Add to Edge

Add to Edge