A Bimodal Hydrostatic Actuator for Robotic Legs with Compliant Fast Motion and High Lifting Force

Paper and Code

Oct 11, 2022

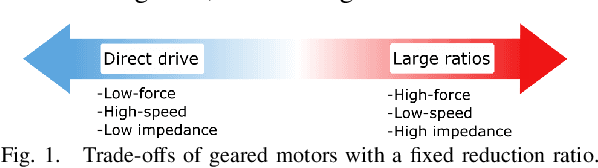

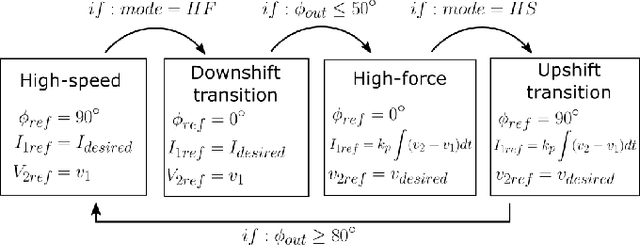

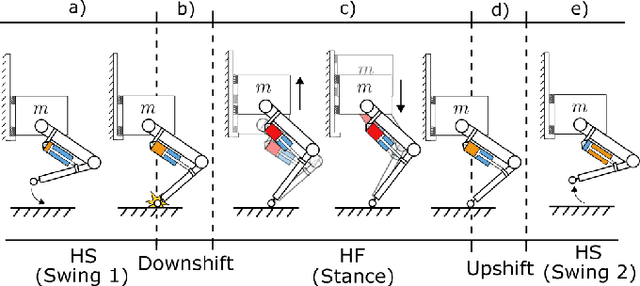

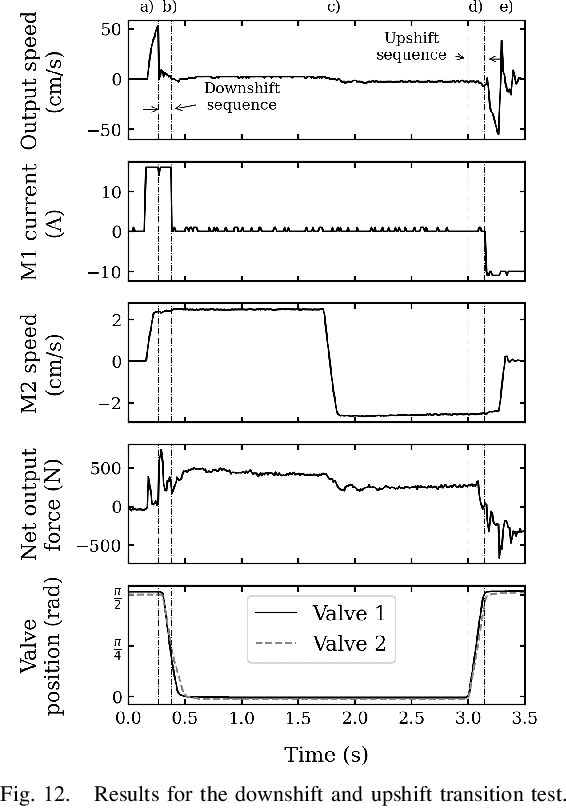

Robotic legs have bimodal operations: swing phases when the leg needs to move quickly in the air (high-speed, low-force) and stance phases when the leg bears the weight of the system (low-speed, high-force). Sizing a traditional single-ratio actuation system for such extremum operations leads to oversized heavy electric motor and poor energy efficiency, which hinder the capability of legged systems that bear the mass of their actuators and energy source. This paper explores an actuation concept where a hydrostatic transmission is dynamically reconfigured using valves to suit the requirements of each phase of a robotic leg. An analysis of the mass-delay-flow trade-off for the switching valve is presented. Then, a custom actuation system is built and integrated on a robotic leg test bench to evaluate the concept. Experimental results show that 1) small motorized ball valves can make fast transitions between operating modes when designed for this task, 2) the proposed operating principle and control schemes allow for seamless transitions, even during an impact with the ground and 3) the actuator characteristics address the needs of a leg bimodal operation in terms of force, speed and compliance.

Add to Chrome

Add to Chrome Add to Firefox

Add to Firefox Add to Edge

Add to Edge