Hongpeng Yin

A Cross-Domain Few-Shot Learning Method Based on Domain Knowledge Mapping

Apr 09, 2025

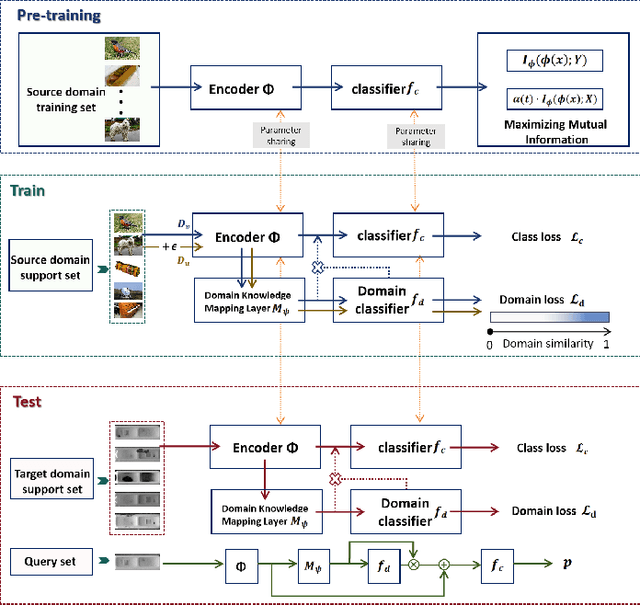

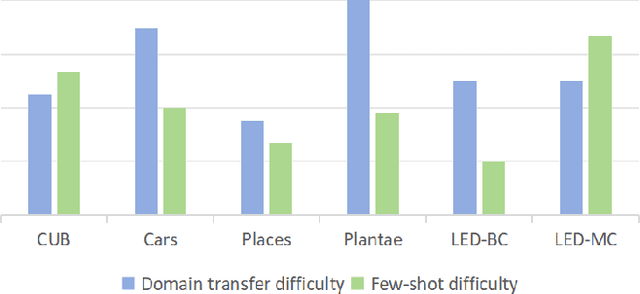

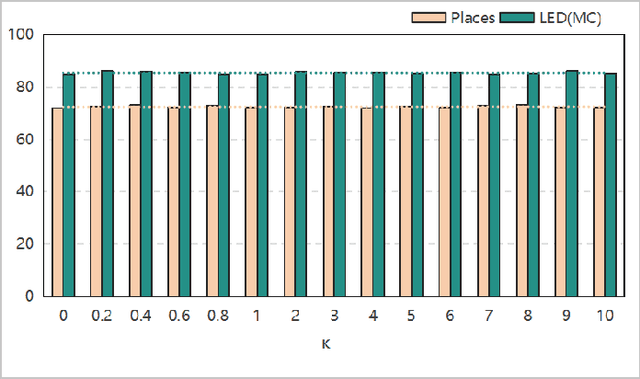

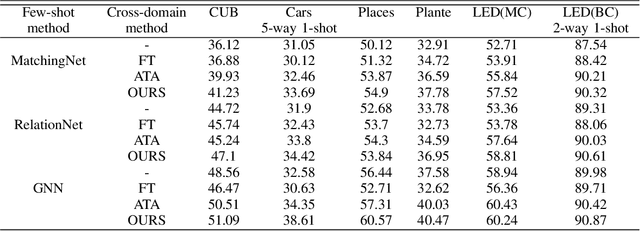

Abstract:In task-based few-shot learning paradigms, it is commonly assumed that different tasks are independently and identically distributed (i.i.d.). However, in real-world scenarios, the distribution encountered in few-shot learning can significantly differ from the distribution of existing data. Thus, how to effectively leverage existing data knowledge to enable models to quickly adapt to class variations under non-i.i.d. assumptions has emerged as a key research challenge. To address this challenge, this paper proposes a new cross-domain few-shot learning approach based on domain knowledge mapping, applied consistently throughout the pre-training, training, and testing phases. In the pre-training phase, our method integrates self-supervised and supervised losses by maximizing mutual information, thereby mitigating mode collapse. During the training phase, the domain knowledge mapping layer collaborates with a domain classifier to learn both domain mapping capabilities and the ability to assess domain adaptation difficulty. Finally, this approach is applied during the testing phase, rapidly adapting to domain variations through meta-training tasks on support sets, consequently enhancing the model's capability to transfer domain knowledge effectively. Experimental validation conducted across six datasets from diverse domains demonstrates the effectiveness of the proposed method.

Robust Unsupervised Fault Diagnosis For High-Dimensional Nonlinear Noisy Data

Mar 11, 2025Abstract:Traditional fault diagnosis methods struggle to handle fault data, with complex data characteristics such as high dimensions and large noise. Deep learning is a promising solution, which typically works well only when labeled fault data are available. To address these problems, a robust unsupervised fault diagnosis using machine learning is proposed in this paper. First, a special dimension reduction method for the high-dimensional fault data is designed. Second, the extracted features are enhanced by incorporating nonlinear information through the learning of a graph structure. Third, to alleviate the problem of reduced fault-diagnosis accuracy attributed to noise and outliers, $l_{2,1}$-norm and typicality-aware constraints are introduced from the perspective of model optimization, respectively. Finally, this paper provides comprehensive theoretical and experimental evidence supporting the effectiveness and robustness of the proposed method. The experiments on both the benchmark Tennessee-Eastman process and a real hot-steel milling process show that the proposed method exhibits better robustness compared to other methods, maintaining high diagnostic accuracy even in the presence of outliers or noise.

SRTFD: Scalable Real-Time Fault Diagnosis through Online Continual Learning

Aug 11, 2024

Abstract:Fault diagnosis (FD) is essential for maintaining operational safety and minimizing economic losses by detecting system abnormalities. Recently, deep learning (DL)-driven FD methods have gained prominence, offering significant improvements in precision and adaptability through the utilization of extensive datasets and advanced DL models. Modern industrial environments, however, demand FD methods that can handle new fault types, dynamic conditions, large-scale data, and provide real-time responses with minimal prior information. Although online continual learning (OCL) demonstrates potential in addressing these requirements by enabling DL models to continuously learn from streaming data, it faces challenges such as data redundancy, imbalance, and limited labeled data. To overcome these limitations, we propose SRTFD, a scalable real-time fault diagnosis framework that enhances OCL with three critical methods: Retrospect Coreset Selection (RCS), which selects the most relevant data to reduce redundant training and improve efficiency; Global Balance Technique (GBT), which ensures balanced coreset selection and robust model performance; and Confidence and Uncertainty-driven Pseudo-label Learning (CUPL), which updates the model using unlabeled data for continuous adaptation. Extensive experiments on a real-world dataset and two public simulated datasets demonstrate SRTFD's effectiveness and potential for providing advanced, scalable, and precise fault diagnosis in modern industrial systems.

Add to Chrome

Add to Chrome Add to Firefox

Add to Firefox Add to Edge

Add to Edge