Hannah S. Stuart

Robotically adjustable kinematics in a wrist-driven orthosis eases grasping across tasks

Jul 22, 2024Abstract:Without finger function, people with C5-7 spinal cord injury (SCI) regularly utilize wrist extension to passively close the fingers and thumb together for grasping. Wearable assistive grasping devices often focus on this familiar wrist-driven technique to provide additional support and amplify grasp force. Despite recent research advances in modernizing these tools, people with SCI often abandon such wearable assistive devices in the long term. We suspect that the wrist constraints imposed by such devices generate undesirable reach and grasp kinematics. Here we show that using continuous robotic motor assistance to give users more adaptability in their wrist posture prior to wrist-driven grasping reduces task difficulty and perceived exertion. Our results demonstrate that more free wrist mobility allows users to select comfortable and natural postures depending on task needs, which improves the versatility of the assistive grasping device for easier use across different hand poses in the arm's workspace. This behavior holds the potential to improve ease of use and desirability of future device designs through new modes of combining both body-power and robotic automation.

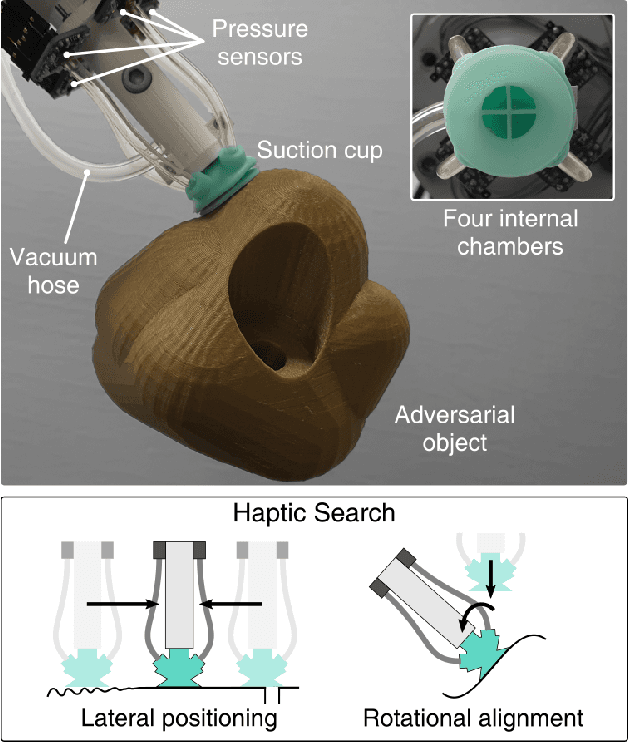

Haptic search with the Smart Suction Cup on adversarial objects

Sep 14, 2023

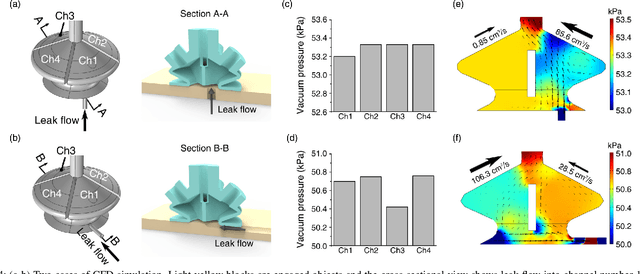

Abstract:Suction cups are an important gripper type in industrial robot applications, and prior literature focuses on using vision-based planners to improve grasping success in these tasks. Vision-based planners can fail due to adversarial objects or lose generalizability for unseen scenarios, without retraining learned algorithms. We propose haptic exploration to improve suction cup grasping when visual grasp planners fail. We present the Smart Suction Cup, an end-effector that utilizes internal flow measurements for tactile sensing. We show that model-based haptic search methods, guided by these flow measurements, improve grasping success by up to 2.5x as compared with using only a vision planner during a bin-picking task. In characterizing the Smart Suction Cup on both geometric edges and curves, we find that flow rate can accurately predict the ideal motion direction even with large postural errors. The Smart Suction Cup includes no electronics on the cup itself, such that the design is easy to fabricate and haptic exploration does not damage the sensor. This work motivates the use of suction cups with autonomous haptic search capabilities in especially adversarial scenarios.

AcousTac: Tactile sensing with acoustic resonance for electronics-free soft skin

Jul 19, 2023

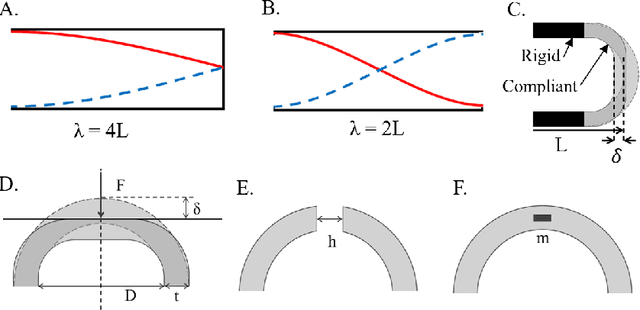

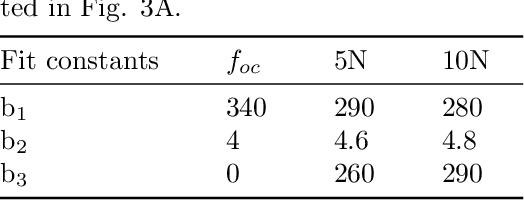

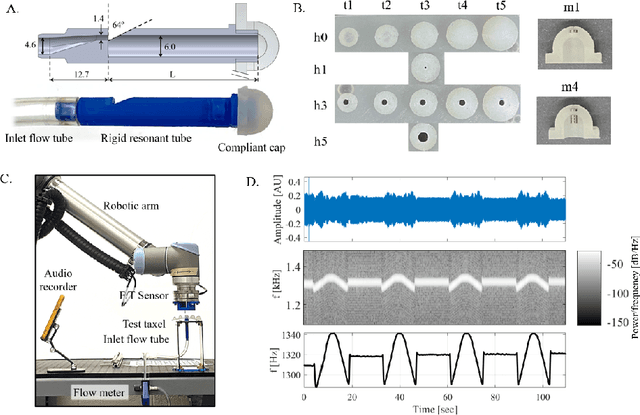

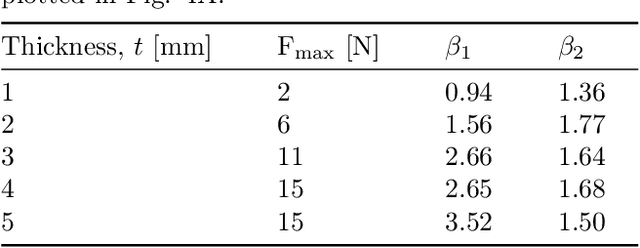

Abstract:Sound is a rich information medium that transmits through air; people communicate through speech and can even discern material through tapping and listening. To capture frequencies in the human hearing range, commercial microphones typically have a sampling rate of over 40kHz. These accessible acoustic technologies are not yet widely adopted for the explicit purpose of giving robots a sense of touch. Some researchers have used sound to sense tactile information, both monitoring ambient soundscape and with embedded speakers and microphones to measure sounds within structures. However, these options commonly do not provide a direct measure of steady state force, or require electronics integrated somewhere near the contact location. In this work, we present AcousTac, an acoustic tactile sensor for electronics-free force sensitive soft skin. Compliant silicone caps and plastic tubes compose the resonant chambers that emit pneumatic-driven sound measurable with a conventional off-board microphone. The resulting frequency changes depend on the external loads on the compliant end caps. We can tune each AcousTac taxel to specific force and frequency ranges, based on geometric parameters, including tube length and end-cap geometry and thus uniquely sense each taxel simultaneously in an array. We demonstrate AcousTac's functionality on two robotic systems: a 4-taxel array and a 3-taxel astrictive gripper. AcousTac is a promising concept for force sensing on soft robotic surfaces, especially in situations where electronics near the contact are not suitable. Equipping robots with tactile sensing and soft skin provides them with a sense of touch and the ability to safely interact with their surroundings.

The Robustness of Tether Friction in Non-idealized Terrains

Aug 22, 2022

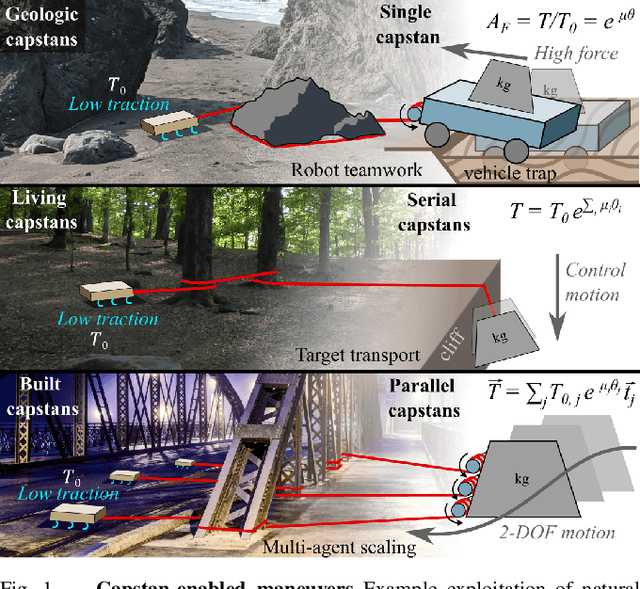

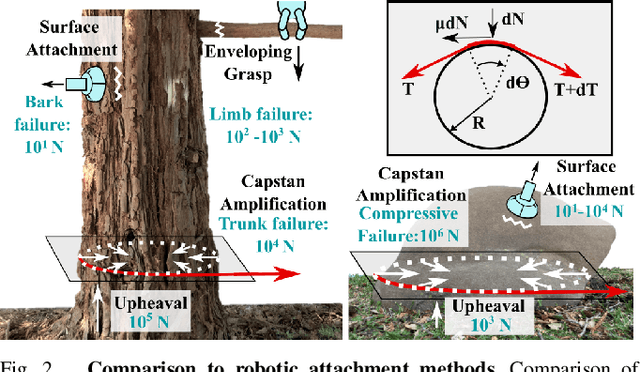

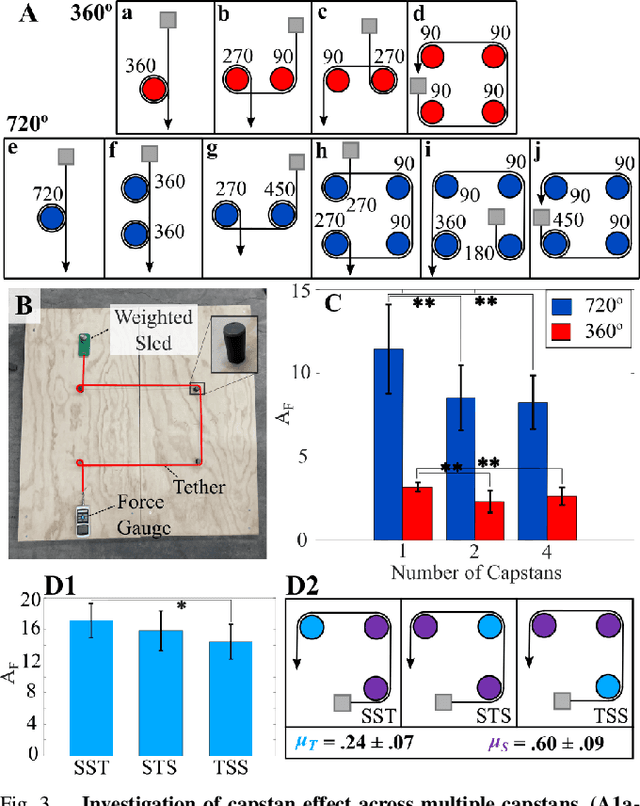

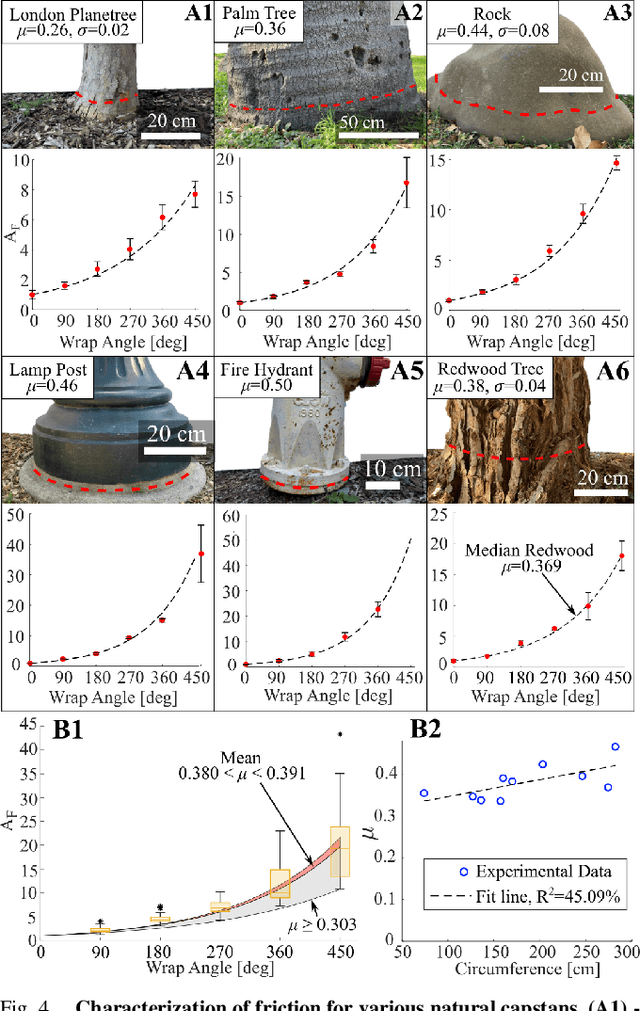

Abstract:Reduced traction limits the ability of mobile robotic systems to resist or apply large external loads, such as tugging a massive payload. One simple and versatile solution is to wrap a tether around naturally occurring objects to leverage the capstan effect and create exponentially-amplified holding forces. Experiments show that an idealized capstan model explains force amplification experienced on common irregular outdoor objects - trees, rocks, posts. Robust to variable environmental conditions, this exponential amplification method can harness single or multiple capstan objects, either in series or in parallel with a team of robots. This adaptability allows for a range of potential configurations especially useful for when objects cannot be fully encircled or gripped. These principles are demonstrated with mobile platforms to (1) control the lowering and arrest of a payload, (2) to achieve planar control of a payload, and (3) to act as an anchor point for a more massive platform to winch towards. We show the simple addition of a tether, wrapped around shallow stones in sand, amplifies holding force of a low-traction platform by up to 774x.

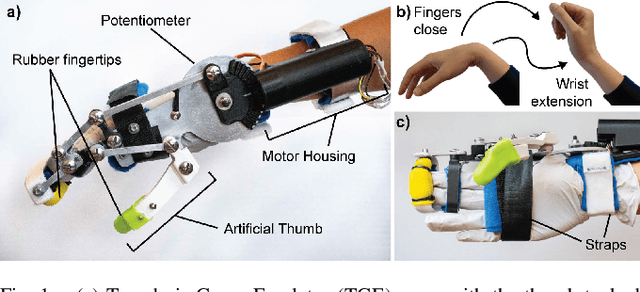

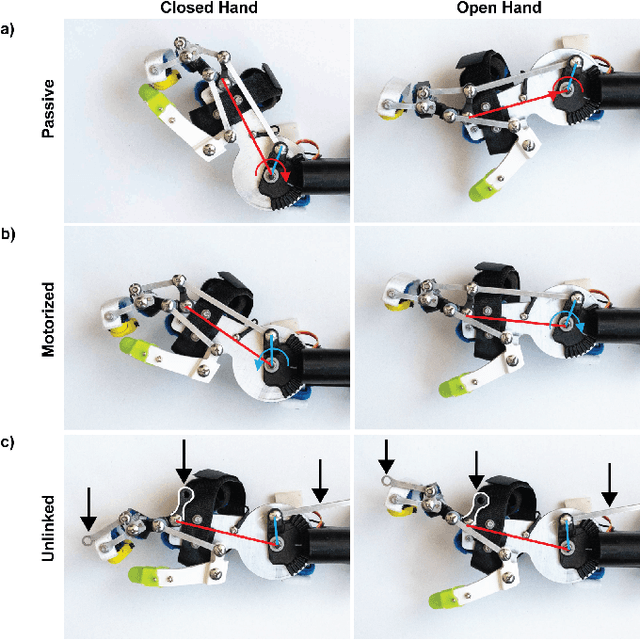

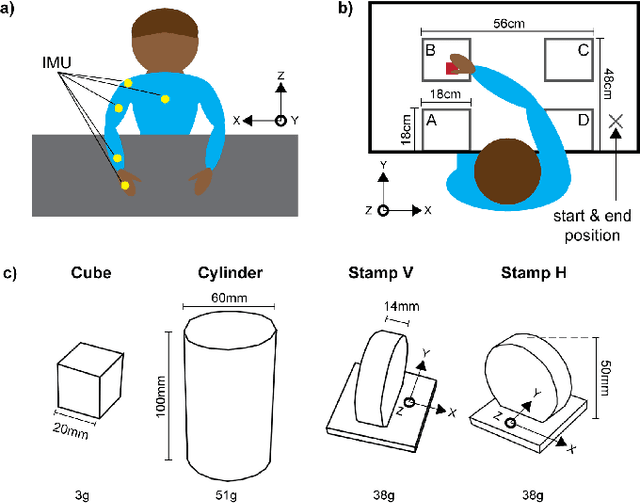

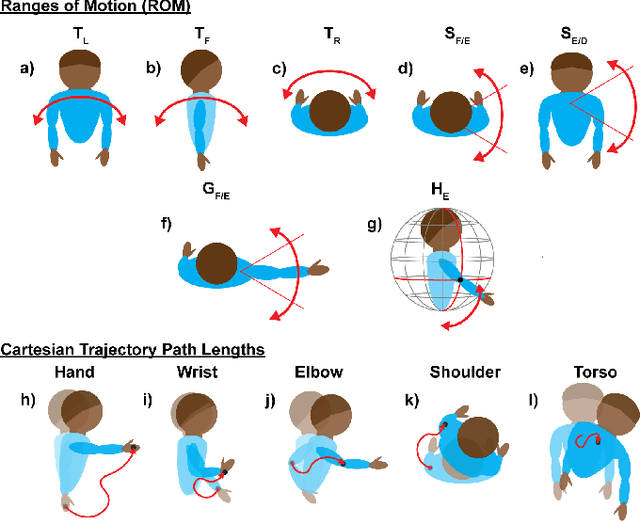

Tenodesis Grasp Emulator: Kinematic Assessment of Wrist-Driven Orthotic Control

Nov 22, 2021

Abstract:Wrist-driven orthotics have been designed to assist people with C6-7 spinal cord injury, however, the kinematic constraint imposed by such a control strategy can impede mobility and lead to abnormal body motion. This study characterizes body compensation using the novel Tenodesis Grasp Emulator, an adaptor orthotic that allows for the investigation of tenodesis grasping in subjects with unimpaired hand function. Subjects perform a series of grasp-and-release tasks in order to compare normal (test control) and constrained wrist-driven modes, showing significant compensation as a result of the constraint. A motor-augmented mode is also compared against traditional wrist-driven operation, to explore the potential role of hybrid human-robot control. We find that both the passive wrist-driven and motor-augmented modes fulfill different roles throughout various tasks tested. Thus, we conclude that a flexible control scheme that can alter intervention based on the task at hand holds the potential to reduce compensation in future work.

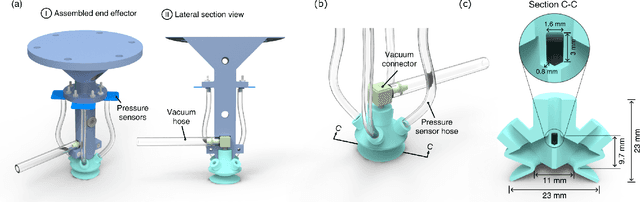

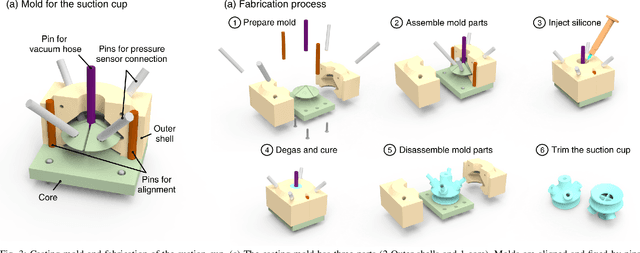

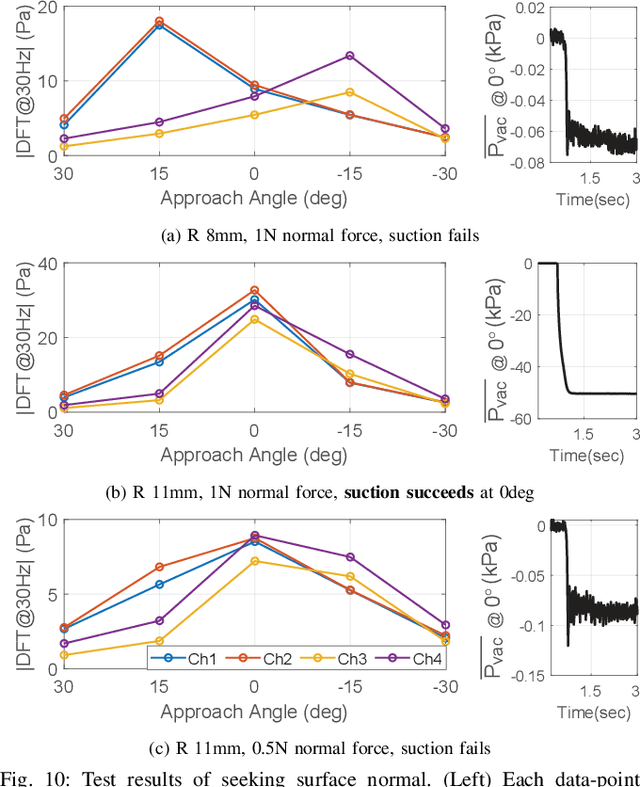

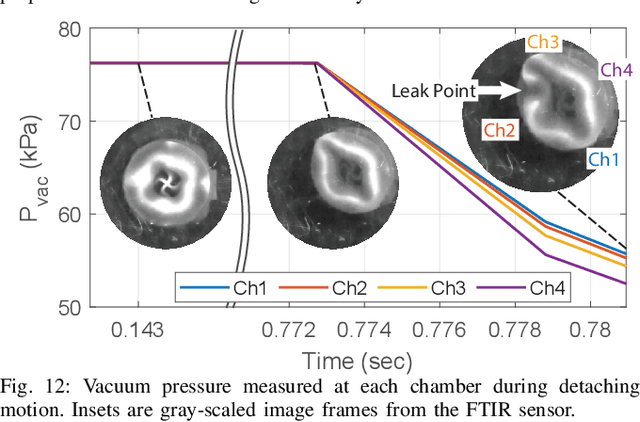

A Multi-Chamber Smart Suction Cup for Adaptive Gripping and Haptic Exploration

May 05, 2021

Abstract:We present a novel robot end-effector for gripping and haptic exploration. Tactile sensing through suction flow monitoring is applied to a new suction cup design that contains multiple chambers for air flow. Each chamber connects with its own remote pressure transducer, which enables both absolute and differential pressure measures between chambers. By changing the overall vacuum applied to this smart suction cup, it can perform different functions such as gentle haptic exploration (low pressure) and monitoring breaks in the seal during strong astrictive gripping (high pressure). Haptic exploration of surfaces through sliding and palpation can guide the selection of suction grasp locations and help to identify the local surface geometry. During suction gripping, this design localizes breaks in the suction seal between four quadrants with up to 97% accuracy and detects breaks in the suction seal early enough to avoid total grasp failure.

Add to Chrome

Add to Chrome Add to Firefox

Add to Firefox Add to Edge

Add to Edge