David May

Hybrid machine learning based scale bridging framework for permeability prediction of fibrous structures

Feb 07, 2025Abstract:This study introduces a hybrid machine learning-based scale-bridging framework for predicting the permeability of fibrous textile structures. By addressing the computational challenges inherent to multiscale modeling, the proposed approach evaluates the efficiency and accuracy of different scale-bridging methodologies combining traditional surrogate models and even integrating physics-informed neural networks (PINNs) with numerical solvers, enabling accurate permeability predictions across micro- and mesoscales. Four methodologies were evaluated: Single Scale Method (SSM), Simple Upscaling Method (SUM), Scale-Bridging Method (SBM), and Fully Resolved Model (FRM). SSM, the simplest method, neglects microscale permeability and exhibited permeability values deviating by up to 150\% of the FRM model, which was taken as ground truth at an equivalent lower fiber volume content. SUM improved predictions by considering uniform microscale permeability, yielding closer values under similar conditions, but still lacked structural variability. The SBM method, incorporating segment-based microscale permeability assignments, showed significant enhancements, achieving almost equivalent values while maintaining computational efficiency and modeling runtimes of ~45 minutes per simulation. In contrast, FRM, which provides the highest fidelity by fully resolving microscale and mesoscale geometries, required up to 270 times more computational time than SSM, with model files exceeding 300 GB. Additionally, a hybrid dual-scale solver incorporating PINNs has been developed and shows the potential to overcome generalization errors and the problem of data scarcity of the data-driven surrogate approaches. The hybrid framework advances permeability modelling by balancing computational cost and prediction reliability, laying the foundation for further applications in fibrous composite manufacturing.

The Role of Cross-Silo Federated Learning in Facilitating Data Sharing in the Agri-Food Sector

Apr 14, 2021

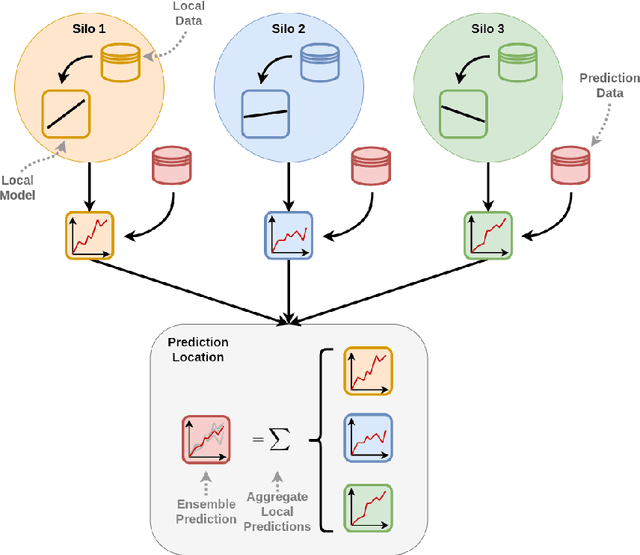

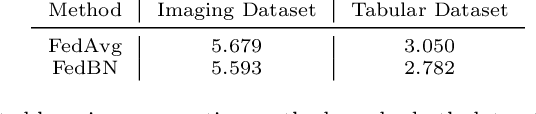

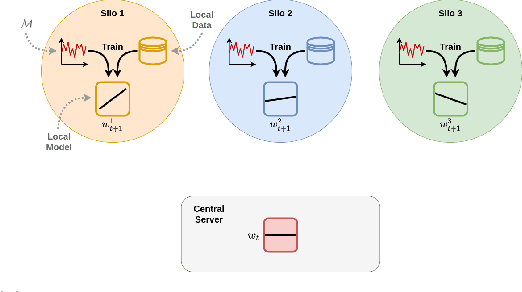

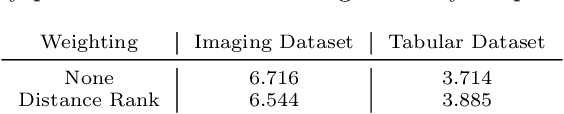

Abstract:Data sharing remains a major hindering factor when it comes to adopting emerging AI technologies in general, but particularly in the agri-food sector. Protectiveness of data is natural in this setting; data is a precious commodity for data owners, which if used properly can provide them with useful insights on operations and processes leading to a competitive advantage. Unfortunately, novel AI technologies often require large amounts of training data in order to perform well, something that in many scenarios is unrealistic. However, recent machine learning advances, e.g. federated learning and privacy-preserving technologies, can offer a solution to this issue via providing the infrastructure and underpinning technologies needed to use data from various sources to train models without ever sharing the raw data themselves. In this paper, we propose a technical solution based on federated learning that uses decentralized data, (i.e. data that are not exchanged or shared but remain with the owners) to develop a cross-silo machine learning model that facilitates data sharing across supply chains. We focus our data sharing proposition on improving production optimization through soybean yield prediction, and provide potential use-cases that such methods can assist in other problem settings. Our results demonstrate that our approach not only performs better than each of the models trained on an individual data source, but also that data sharing in the agri-food sector can be enabled via alternatives to data exchange, whilst also helping to adopt emerging machine learning technologies to boost productivity.

Add to Chrome

Add to Chrome Add to Firefox

Add to Firefox Add to Edge

Add to Edge