Chee Khiang Pang

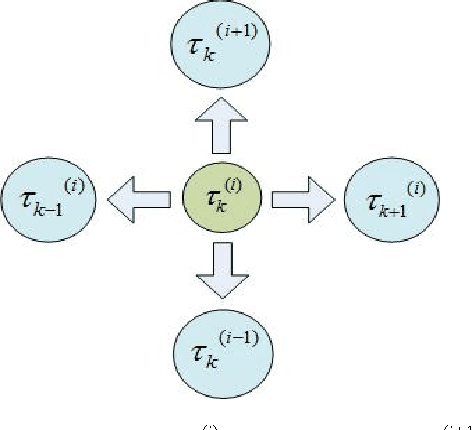

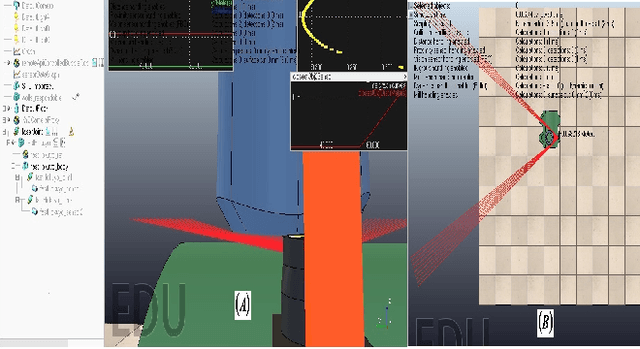

Object Detection and Motion Planning for Automated Welding of Tubular Joints

Sep 27, 2018

Abstract:Automatic welding of tubular TKY joints is an important and challenging task for the marine and offshore industry. In this paper, a framework for tubular joint detection and motion planning is proposed. The pose of the real tubular joint is detected using RGB-D sensors, which is used to obtain a real-to-virtual mapping for positioning the workpiece in a virtual environment. For motion planning, a Bi-directional Transition based Rapidly exploring Random Tree (BiTRRT) algorithm is used to generate trajectories for reaching the desired goals. The complete framework is verified with experiments, and the results show that the robot welding torch is able to transit without collision to desired goals which are close to the tubular joint.

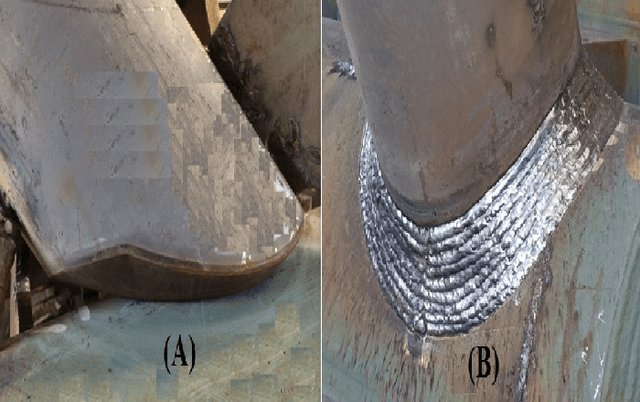

Model-Free 3D Reconstruction of Weld Joint Using Laser Scanning

Jul 08, 2015

Abstract:This article presents a novel utilization of the concept of entropy in information theory to model-free 3D reconstruction of weld joint in presence of noise. We show that our formulation attains its global minimum at the upper edge of this joint. This property significantly simplifies the extraction of this welding joint. Furthermore, we present an approach to compute the volume of this extracted space to facilitate the monitoring of the progress of the welding task. Moreover, we provide a preliminary analysis of the effect of variation of the noise on the extraction process of this space to realize the impact of this noise on the computation of its area and volume.

Application of Deep Neural Network in Estimation of the Weld Bead Parameters

Jul 08, 2015

Abstract:We present a deep learning approach to estimation of the bead parameters in welding tasks. Our model is based on a four-hidden-layer neural network architecture. More specifically, the first three hidden layers of this architecture utilize Sigmoid function to produce their respective intermediate outputs. On the other hand, the last hidden layer uses a linear transformation to generate the final output of this architecture. This transforms our deep network architecture from a classifier to a non-linear regression model. We compare the performance of our deep network with a selected number of results in the literature to show a considerable improvement in reducing the errors in estimation of these values. Furthermore, we show its scalability on estimating the weld bead parameters with same level of accuracy on combination of datasets that pertain to different welding techniques. This is a nontrivial result that is counter-intuitive to the general belief in this field of research.

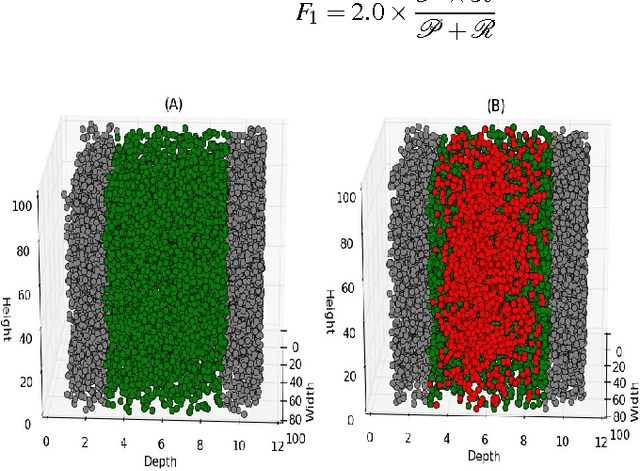

An Adaptive Sampling Approach to 3D Reconstruction of Weld Joint

Jul 08, 2015

Abstract:We present an adaptive sampling approach to 3D reconstruction of the welding joint using the point cloud that is generated by a laser sensor. We start with a randomized strategy to approximate the surface of the volume of interest through selection of a number of pivotal candidates. Furthermore, we introduce three proposal distributions over the neighborhood of each of these pivots to adaptively sample from their neighbors to refine the original randomized approximation to incrementally reconstruct this welding space. We prevent our algorithm from being trapped in a neighborhood via permanently labeling the visited samples. In addition, we accumulate the accepted candidates along with their selected neighbors in a queue structure to allow every selected sample to contribute to the evolution of the reconstructed welding space as the algorithm progresses. We analyze the performance of our adaptive sampling algorithm in contrast to the random sampling, with and without replacement, to show a significant improvement in total number of samples that are drawn to identify the region of interest, thereby expanding upon neighboring samples to extract the entire region in a fewer iterations and a shorter computation time.

Add to Chrome

Add to Chrome Add to Firefox

Add to Firefox Add to Edge

Add to Edge