Błażej Leporowski

Audio-Visual Dataset and Method for Anomaly Detection in Traffic Videos

May 24, 2023

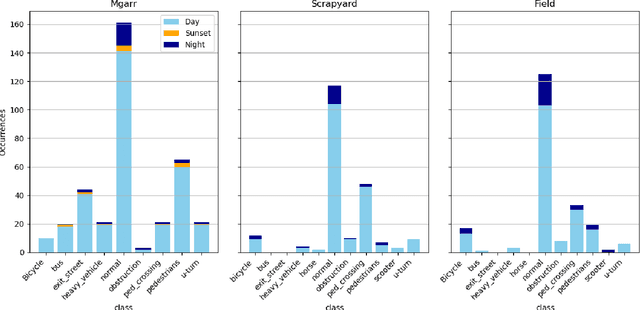

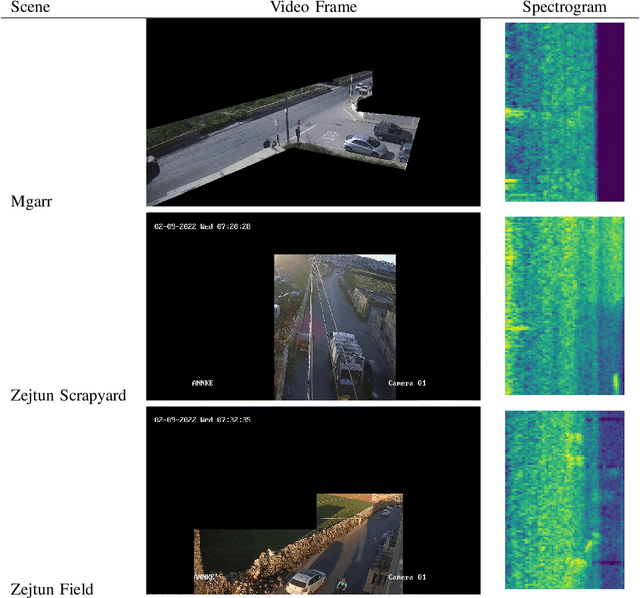

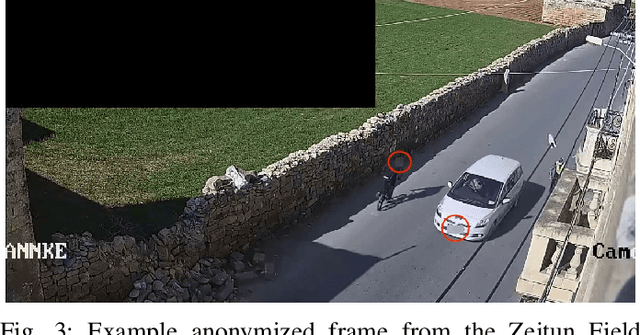

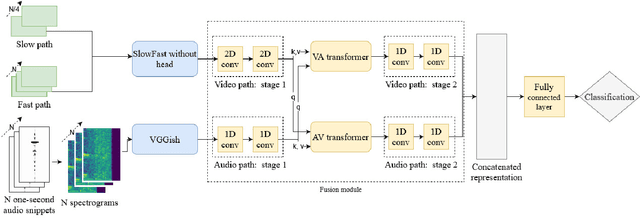

Abstract:We introduce the first audio-visual dataset for traffic anomaly detection taken from real-world scenes, called MAVAD, with a diverse range of weather and illumination conditions. In addition, we propose a novel method named AVACA that combines visual and audio features extracted from video sequences by means of cross-attention to detect anomalies. We demonstrate that the addition of audio improves the performance of AVACA by up to 5.2%. We also evaluate the impact of image anonymization, showing only a minor decrease in performance averaging at 1.7%.

Analysis of the Effect of Low-Overhead Lossy Image Compression on the Performance of Visual Crowd Counting for Smart City Applications

Jul 20, 2022

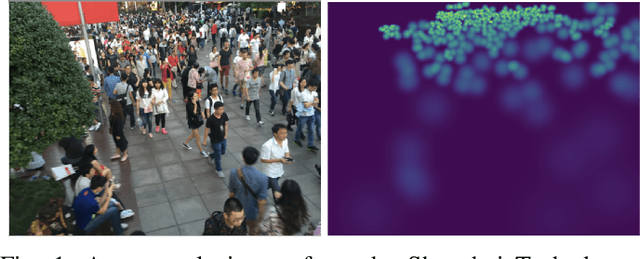

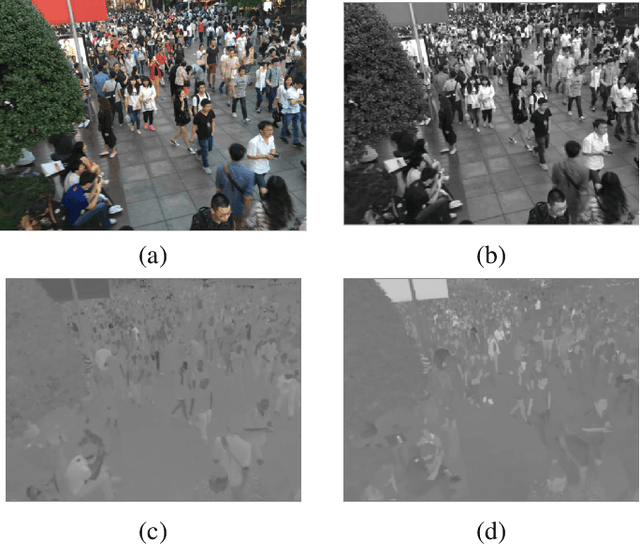

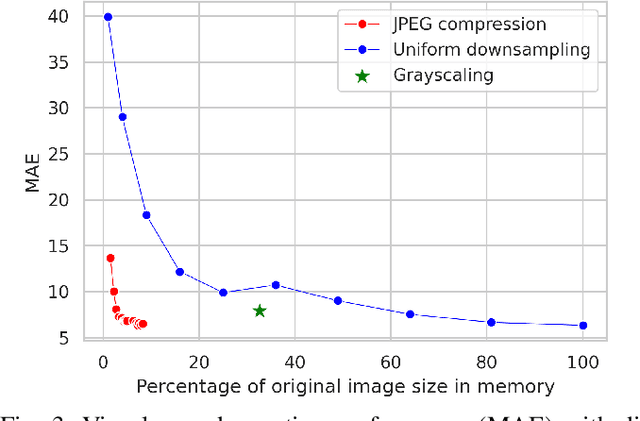

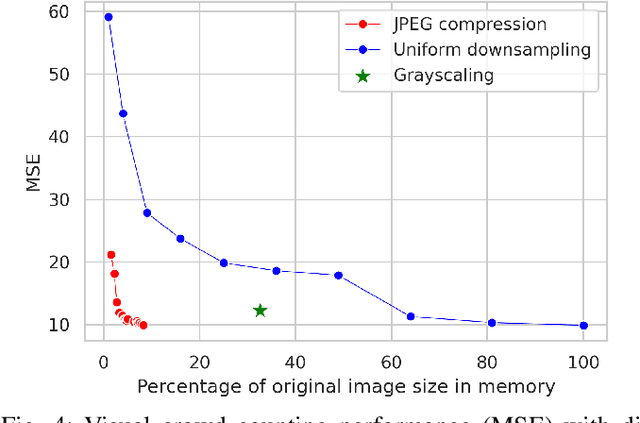

Abstract:Images and video frames captured by cameras placed throughout smart cities are often transmitted over the network to a server to be processed by deep neural networks for various tasks. Transmission of raw images, i.e., without any form of compression, requires high bandwidth and can lead to congestion issues and delays in transmission. The use of lossy image compression techniques can reduce the quality of the images, leading to accuracy degradation. In this paper, we analyze the effect of applying low-overhead lossy image compression methods on the accuracy of visual crowd counting, and measure the trade-off between bandwidth reduction and the obtained accuracy.

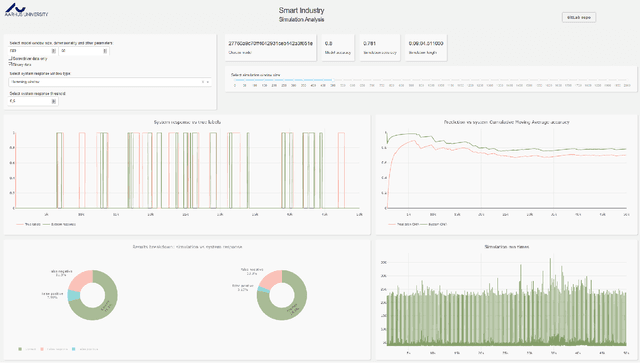

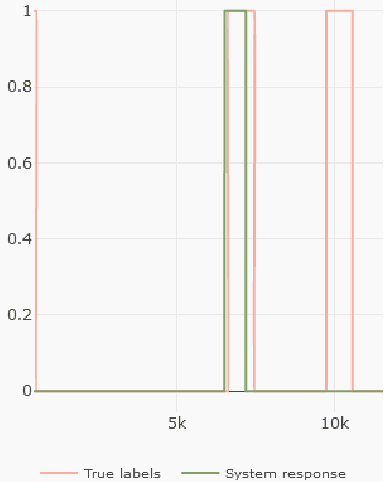

DeepTimeAnomalyViz: A Tool for Visualizing and Post-processing Deep Learning Anomaly Detection Results for Industrial Time-Series

Sep 21, 2021

Abstract:Industrial processes are monitored by a large number of various sensors that produce time-series data. Deep Learning offers a possibility to create anomaly detection methods that can aid in preventing malfunctions and increasing efficiency. But creating such a solution can be a complicated task, with factors such as inference speed, amount of available data, number of sensors, and many more, influencing the feasibility of such implementation. We introduce the DeTAVIZ interface, which is a web browser based visualization tool for quick exploration and assessment of feasibility of DL based anomaly detection in a given problem. Provided with a pool of pretrained models and simulation results, DeTAVIZ allows the user to easily and quickly iterate through multiple post processing options and compare different models, and allows for manual optimisation towards a chosen metric.

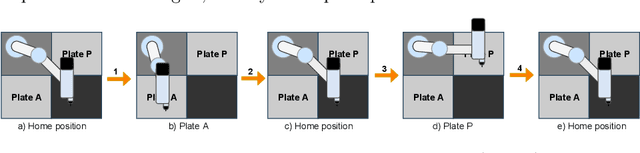

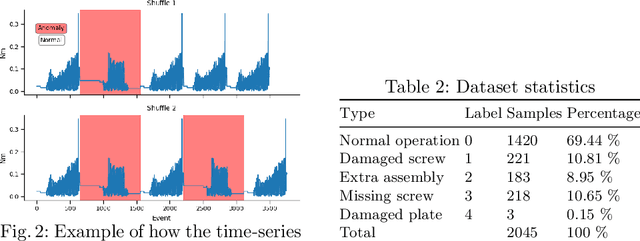

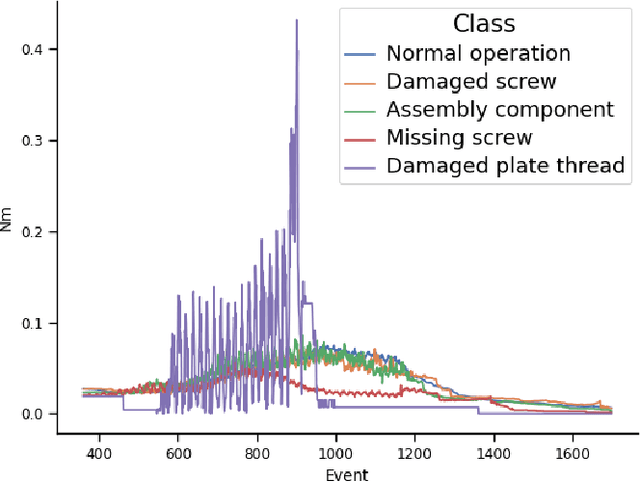

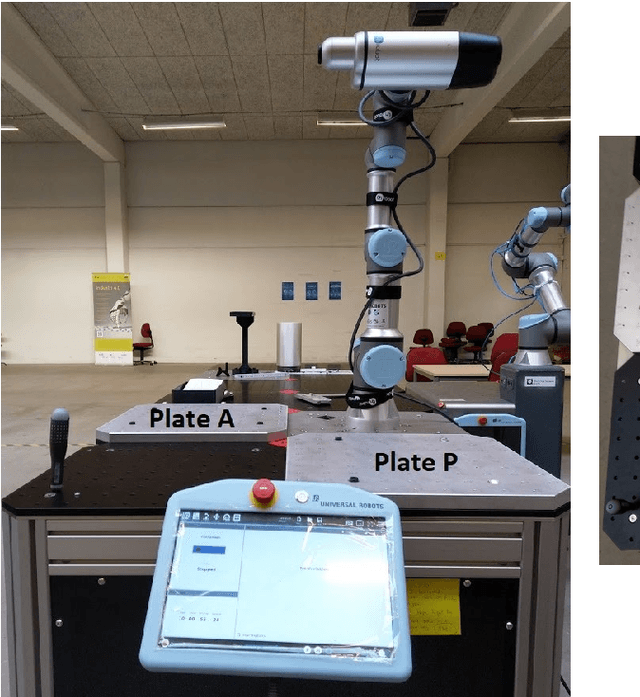

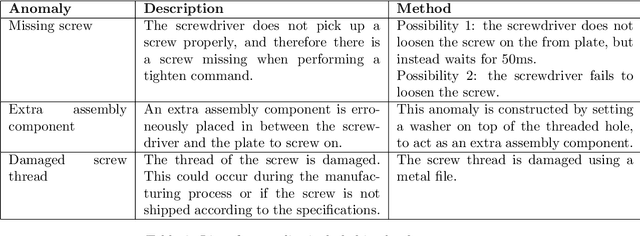

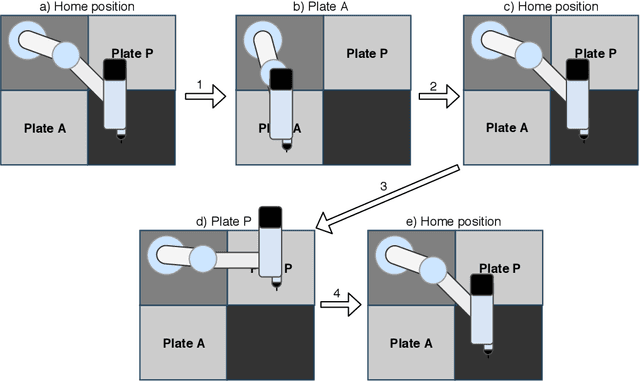

Detecting Faults during Automatic Screwdriving: A Dataset and Use Case of Anomaly Detection for Automatic Screwdriving

Jul 05, 2021

Abstract:Detecting faults in manufacturing applications can be difficult, especially if each fault model is to be engineered by hand. Data-driven approaches, using Machine Learning (ML) for detecting faults have recently gained increasing interest, where a ML model can be trained on a set of data from a manufacturing process. In this paper, we present a use case of using ML models for detecting faults during automated screwdriving operations, and introduce a new dataset containing fully monitored and registered data from a Universal Robot and OnRobot screwdriver during both normal and anomalous operations. We illustrate, with the use of two time-series ML models, how to detect faults in an automated screwdriving application.

Visualising Deep Network's Time-Series Representations

Mar 12, 2021

Abstract:Despite the popularisation of the machine learning models, more often than not they still operate as black boxes with no insight into what is happening inside the model. There exist a few methods that allow to visualise and explain why the model has made a certain prediction. Those methods, however, allow viewing the causal link between the input and output of the model without presenting how the model learns to represent the data. In this paper, a method that addresses that issue is proposed, with a focus on visualising multi-dimensional time-series data. Experiments on a high-frequency stock market dataset show that the method provides fast and discernible visualisations. Large datasets can be visualised quickly and on one plot, which makes it easy for a user to compare the learned representations of the data. The developed method successfully combines known and proven techniques to provide novel insight into the inner workings of time-series classifier models.

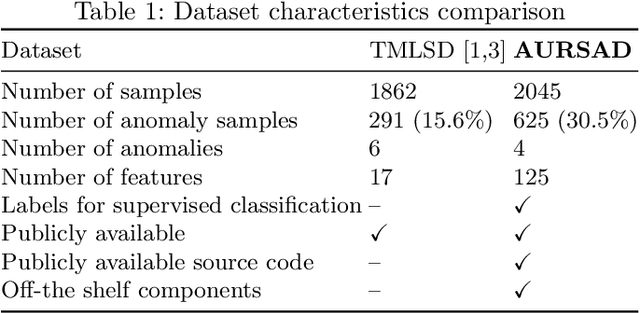

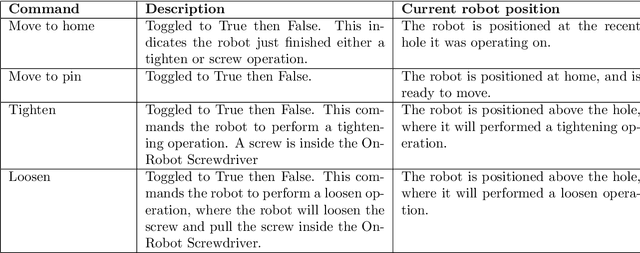

AURSAD: Universal Robot Screwdriving Anomaly Detection Dataset

Feb 06, 2021

Abstract:Screwdriving is one of the most popular industrial processes. As such, it is increasingly common to automate that procedure by using various robots. Even though the automation increases the efficiency of the screwdriving process, if the process is not monitored correctly, faults may occur during operation, which can impact the effectiveness and quality of assembly. Machine Learning (ML) has the potential to detect those undesirable events and limit their impact. In order to do so, first a dataset that fully describes the operation of an industrial robot performing automated screwdriving must be available. This report describes a dataset created using a UR3e series robot and OnRobot Screwdriver. We create different scenarios and introduce 4 types of anomalies to the process while all available robot and screwdriver sensors are continuously recorded. The resulting data contains 2042 samples of normal and anomalous robot operation. Brief ML benchmarks using this data are also provided, showcasing the data's suitability and potential for further analysis and experimentation.

Add to Chrome

Add to Chrome Add to Firefox

Add to Firefox Add to Edge

Add to Edge