Daniella Tola

Enabling Digitalization in Modular Robotic Systems Integration

Jan 04, 2024Abstract:Integrating robot systems into manufacturing lines is a time-consuming process. In the era of digitalization, the research and development of new technologies is crucial for improving integration processes. Numerous challenges, including the lack of standardization, as well as intricate stakeholder relationships, complicate the process of robotic systems integration. This process typically consists of acquisition, integration, and deployment of the robot systems. This thesis focuses on three areas that help automate and simplify robotic systems integration. In the first area, related to acquisition, a constraint-based configurator is demonstrated that resolves compatibility challenges between robot devices, and automates the configuration process. This reduces the risk of integrating incompatible devices and decreases the need for experts during the configuration phase. In the second area, related to integration, the interoperable modeling format, Unified Robot Description Format (URDF), is investigated, where a detailed analysis is performed, revealing significant inconsistencies and critical improvements. This format is widely used for kinematic modeling and 3D visualization of robots, and its models can be reused across simulation tools. Improving this format benefits a wide range of users, including robotics engineers, researchers, and students. In the third area, related to deployment, Digital Twins (DTs) for robot systems are explored, as these improve efficiency and reduce downtime. A comprehensive literature review of DTs is conducted, and a case study of modular robot systems is developed. This research can accelerate the adoption of DTs in the robotics industry. These insights and approaches improve the process of robotic systems integration, offering valuable contributions that future research can build upon, ultimately driving efficiency, and reducing costs.

Understanding URDF: A Dataset and Analysis

Aug 01, 2023

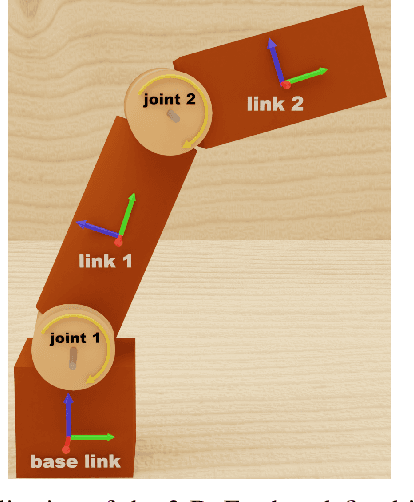

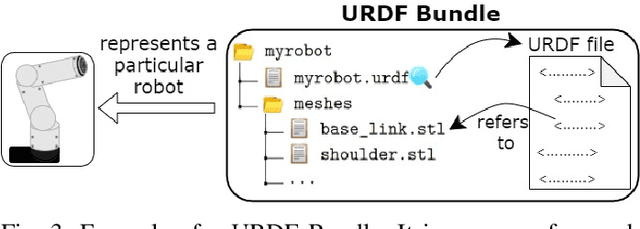

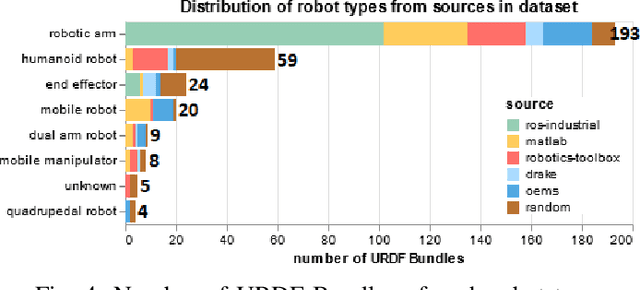

Abstract:As the complexity of robot systems increases, it becomes more effective to simulate them before deployment. To do this, a model of the robot's kinematics or dynamics is required, and the most commonly used format is the Unified Robot Description Format (URDF). This article presents, to our knowledge, the first dataset of URDF files from various industrial and research organizations, with metadata describing each robot, its type, manufacturer, and the source of the model. The dataset contains 322 URDF files of which 195 are unique robot models, meaning the excess URDFs are either of a robot that is multiply defined across sources or URDF variants of the same robot. We analyze the files in the dataset, where we, among other things, provide information on how they were generated, which mesh file types are most commonly used, and compare models of multiply defined robots. The intention of this article is to build a foundation of knowledge on URDF and how it is used based on publicly available URDF files. Publishing the dataset, analysis, and the scripts and tools used enables others using, researching or developing URDFs to easily access this data and use it in their own work.

Understanding URDF: A Survey Based on User Experience

Mar 12, 2023

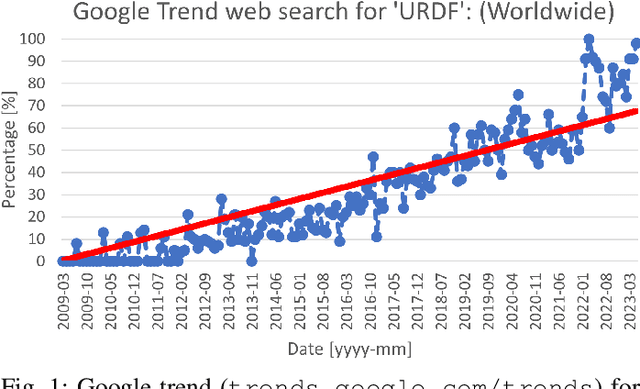

Abstract:With the increasing complexity of robot systems, it is necessary to simulate them before deployment. To do this, a model of the robot's kinematics or dynamics is required. One of the most commonly used formats for modeling robots is the Unified Robot Description Format (URDF). The goal of this article is to understand how URDF is currently used, what challenges people face when working with it, and how the community sees the future of URDF. The outcome can potentially be used to guide future research. This article presents the results from a survey based on 510 anonymous responses from robotic developers of different backgrounds and levels of experience. We find that 96.8% of the participants have simulated robots before, and of them 95.5% had used URDF. We identify a number of challenges and limitations that complicate the use of URDF, such as the inability to model parallel linkages and closed-chain systems, no real standard, lack of documentation, and a limited number of dynamic parameters to model the robot. Future perspectives for URDF are also determined, where 53.5% believe URDF will be more commonly used in the future, 12.2% believe other standards or tools will make URDF obsolete, and 34.4% are not sure what the future of URDF will be. Most participants agree that there is a need for better tooling to ensure URDF's future use.

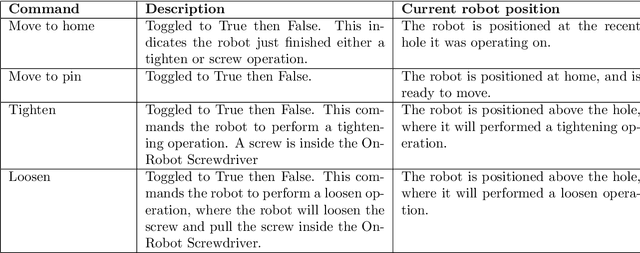

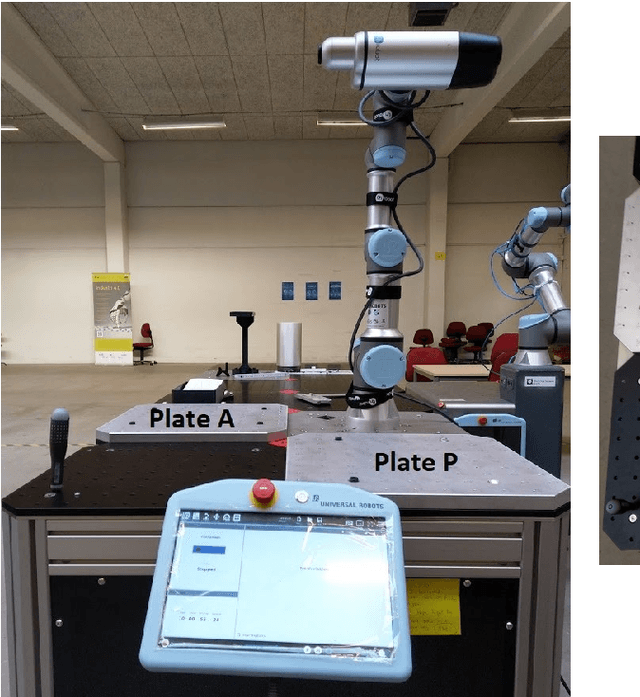

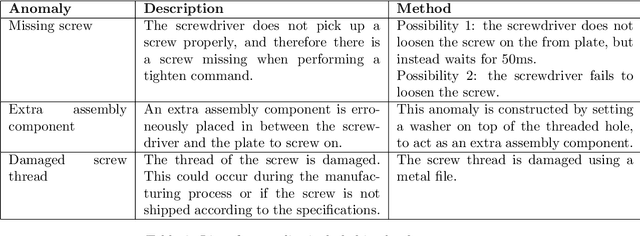

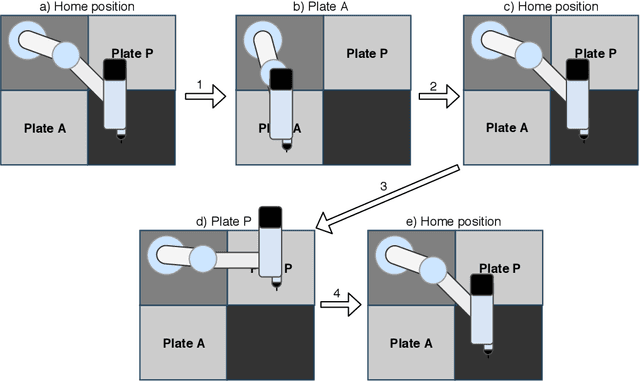

Detecting Faults during Automatic Screwdriving: A Dataset and Use Case of Anomaly Detection for Automatic Screwdriving

Jul 05, 2021

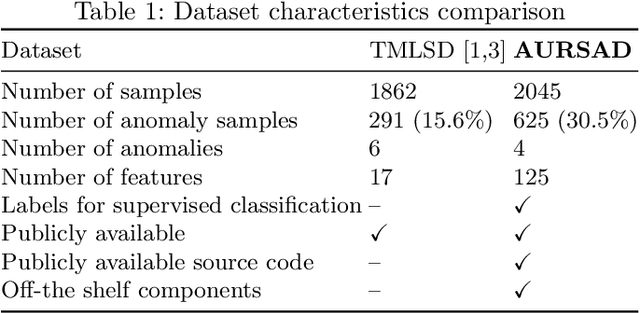

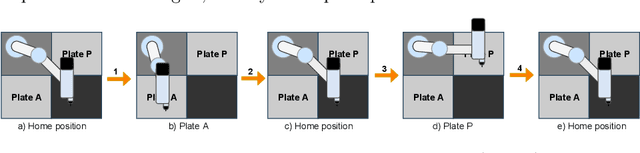

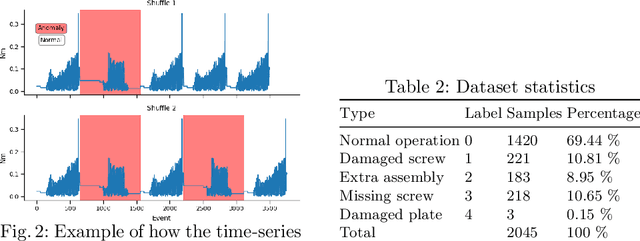

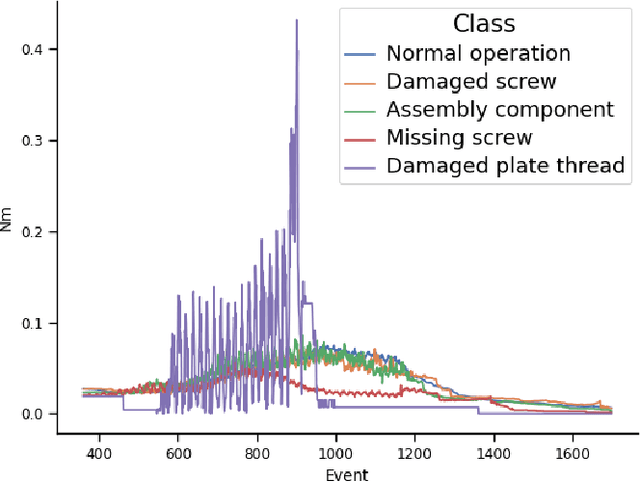

Abstract:Detecting faults in manufacturing applications can be difficult, especially if each fault model is to be engineered by hand. Data-driven approaches, using Machine Learning (ML) for detecting faults have recently gained increasing interest, where a ML model can be trained on a set of data from a manufacturing process. In this paper, we present a use case of using ML models for detecting faults during automated screwdriving operations, and introduce a new dataset containing fully monitored and registered data from a Universal Robot and OnRobot screwdriver during both normal and anomalous operations. We illustrate, with the use of two time-series ML models, how to detect faults in an automated screwdriving application.

AURSAD: Universal Robot Screwdriving Anomaly Detection Dataset

Feb 06, 2021

Abstract:Screwdriving is one of the most popular industrial processes. As such, it is increasingly common to automate that procedure by using various robots. Even though the automation increases the efficiency of the screwdriving process, if the process is not monitored correctly, faults may occur during operation, which can impact the effectiveness and quality of assembly. Machine Learning (ML) has the potential to detect those undesirable events and limit their impact. In order to do so, first a dataset that fully describes the operation of an industrial robot performing automated screwdriving must be available. This report describes a dataset created using a UR3e series robot and OnRobot Screwdriver. We create different scenarios and introduce 4 types of anomalies to the process while all available robot and screwdriver sensors are continuously recorded. The resulting data contains 2042 samples of normal and anomalous robot operation. Brief ML benchmarks using this data are also provided, showcasing the data's suitability and potential for further analysis and experimentation.

Add to Chrome

Add to Chrome Add to Firefox

Add to Firefox Add to Edge

Add to Edge