Alexander C. Ogren

Phononic materials with effectively scale-separated hierarchical features using interpretable machine learning

Aug 15, 2024Abstract:Manipulating the dispersive characteristics of vibrational waves is beneficial for many applications, e.g., high-precision instruments. architected hierarchical phononic materials have sparked promise tunability of elastodynamic waves and vibrations over multiple frequency ranges. In this article, hierarchical unit-cells are obtained, where features at each length scale result in a band gap within a targeted frequency range. Our novel approach, the ``hierarchical unit-cell template method,'' is an interpretable machine-learning approach that uncovers global unit-cell shape/topology patterns corresponding to predefined band-gap objectives. A scale-separation effect is observed where the coarse-scale band-gap objective is mostly unaffected by the fine-scale features despite the closeness of their length scales, thus enabling an efficient hierarchical algorithm. Moreover, the hierarchical patterns revealed are not predefined or self-similar hierarchies as common in current hierarchical phononic materials. Thus, our approach offers a flexible and efficient method for the exploration of new regions in the hierarchical design space, extracting minimal effective patterns for inverse design in applications targeting multiple frequency ranges.

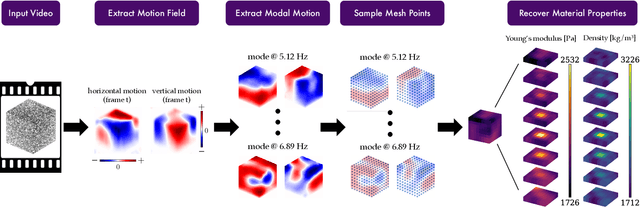

Visual Vibration Tomography: Estimating Interior Material Properties from Monocular Video

Apr 06, 2021

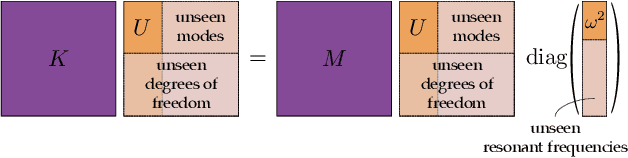

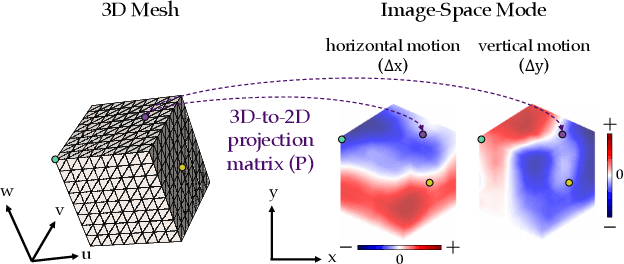

Abstract:An object's interior material properties, while invisible to the human eye, determine motion observed on its surface. We propose an approach that estimates heterogeneous material properties of an object directly from a monocular video of its surface vibrations. Specifically, we estimate Young's modulus and density throughout a 3D object with known geometry. Knowledge of how these values change across the object is useful for characterizing defects and simulating how the object will interact with different environments. Traditional non-destructive testing approaches, which generally estimate homogenized material properties or the presence of defects, are expensive and use specialized instruments. We propose an approach that leverages monocular video to (1) measure and object's sub-pixel motion and decompose this motion into image-space modes, and (2) directly infer spatially-varying Young's modulus and density values from the observed image-space modes. On both simulated and real videos, we demonstrate that our approach is able to image material properties simply by analyzing surface motion. In particular, our method allows us to identify unseen defects on a 2D drum head from real, high-speed video.

Add to Chrome

Add to Chrome Add to Firefox

Add to Firefox Add to Edge

Add to Edge