Performance, Successes and Limitations of Deep Learning Semantic Segmentation of Multiple Defects in Transmission Electron Micrographs

Paper and Code

Oct 15, 2021

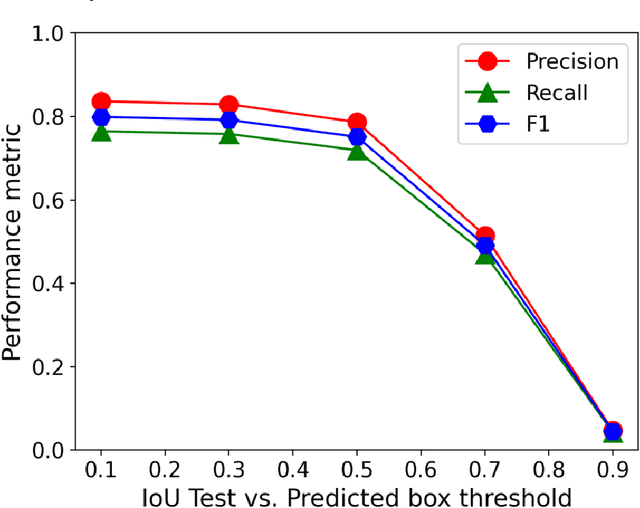

In this work, we perform semantic segmentation of multiple defect types in electron microscopy images of irradiated FeCrAl alloys using a deep learning Mask Regional Convolutional Neural Network (Mask R-CNN) model. We conduct an in-depth analysis of key model performance statistics, with a focus on quantities such as predicted distributions of defect shapes, defect sizes, and defect areal densities relevant to informing modeling and understanding of irradiated Fe-based materials properties. To better understand the performance and present limitations of the model, we provide examples of useful evaluation tests which include a suite of random splits, and dataset size-dependent and domain-targeted cross validation tests. Overall, we find that the current model is a fast, effective tool for automatically characterizing and quantifying multiple defect types in microscopy images, with a level of accuracy on par with human domain expert labelers. More specifically, the model can achieve average defect identification F1 scores as high as 0.8, and, based on random cross validation, have low overall average (+/- standard deviation) defect size and density percentage errors of 7.3 (+/- 3.8)% and 12.7 (+/- 5.3)%, respectively. Further, our model predicts the expected material hardening to within 10-20 MPa (about 10% of total hardening), which is about the same error level as experiments. Our targeted evaluation tests also suggest the best path toward improving future models is not expanding existing databases with more labeled images but instead data additions that target weak points of the model domain, such as images from different microscopes, imaging conditions, irradiation environments, and alloy types. Finally, we discuss the first phase of an effort to provide an easy-to-use, open-source object detection tool to the broader community for identifying defects in new images.

Add to Chrome

Add to Chrome Add to Firefox

Add to Firefox Add to Edge

Add to Edge