An Encoder-Decoder Based Approach for Anomaly Detection with Application in Additive Manufacturing

Paper and Code

Jul 26, 2019

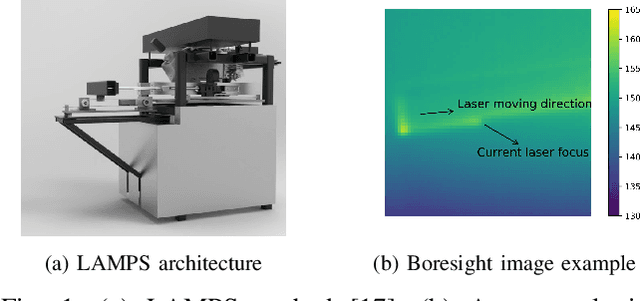

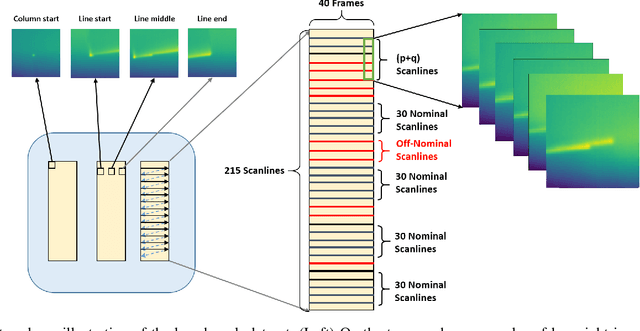

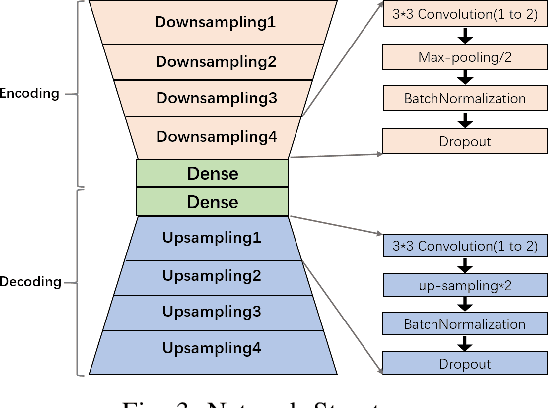

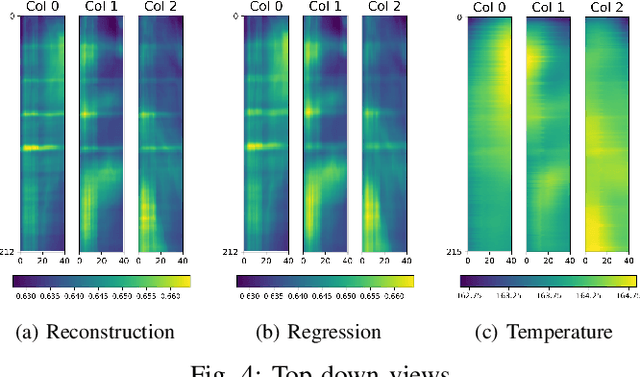

We present a novel unsupervised deep learning approach that utilizes the encoder-decoder architecture for detecting anomalies in sequential sensor data collected during industrial manufacturing. Our approach is designed not only to detect whether there exists an anomaly at a given time step, but also to predict what will happen next in the (sequential) process. We demonstrate our approach on a dataset collected from a real-world testbed. The dataset contains images collected under both normal conditions and synthetic anomalies. We show that the encoder-decoder model is able to identify the injected anomalies in a modern manufacturing process in an unsupervised fashion. In addition, it also gives hints about the temperature non-uniformity of the testbed during manufacturing, which is what we are not aware of before doing the experiment.

Add to Chrome

Add to Chrome Add to Firefox

Add to Firefox Add to Edge

Add to Edge