Yinhua Liu

MRG: A Multi-Robot Manufacturing Digital Scene Generation Method Using Multi-Instance Point Cloud Registration

Jan 03, 2025Abstract:A high-fidelity digital simulation environment is crucial for accurately replicating physical operational processes. However, inconsistencies between simulation and physical environments result in low confidence in simulation outcomes, limiting their effectiveness in guiding real-world production. Unlike the traditional step-by-step point cloud "segmentation-registration" generation method, this paper introduces, for the first time, a novel Multi-Robot Manufacturing Digital Scene Generation (MRG) method that leverages multi-instance point cloud registration, specifically within manufacturing scenes. Tailored to the characteristics of industrial robots and manufacturing settings, an instance-focused transformer module is developed to delineate instance boundaries and capture correlations between local regions. Additionally, a hypothesis generation module is proposed to extract target instances while preserving key features. Finally, an efficient screening and optimization algorithm is designed to refine the final registration results. Experimental evaluations on the Scan2CAD and Welding-Station datasets demonstrate that: (1) the proposed method outperforms existing multi-instance point cloud registration techniques; (2) compared to state-of-the-art methods, the Scan2CAD dataset achieves improvements in MR and MP by 12.15% and 17.79%, respectively; and (3) on the Welding-Station dataset, MR and MP are enhanced by 16.95% and 24.15%, respectively. This work marks the first application of multi-instance point cloud registration in manufacturing scenes, significantly advancing the precision and reliability of digital simulation environments for industrial applications.

Coverage Path Planning for Robotic Quality Inspection with Control on Measurement Uncertainty

Jan 12, 2022

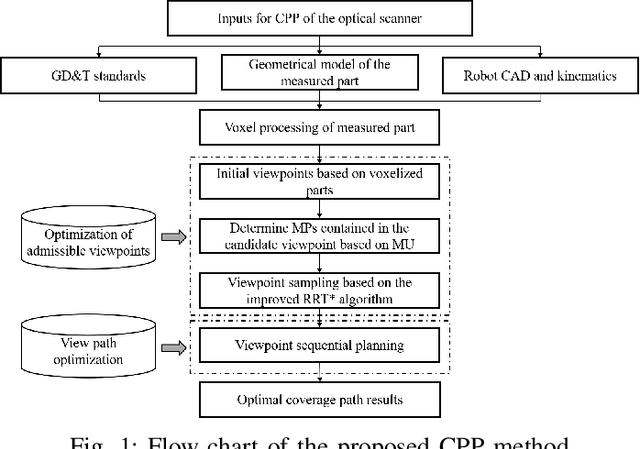

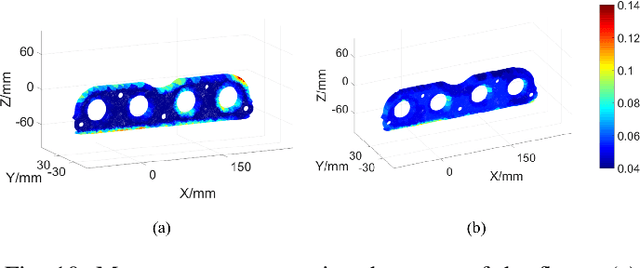

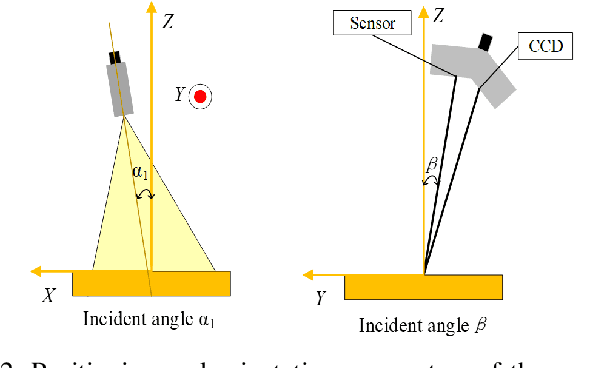

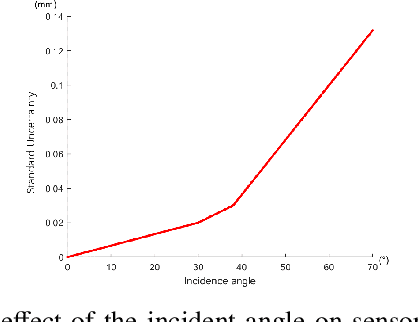

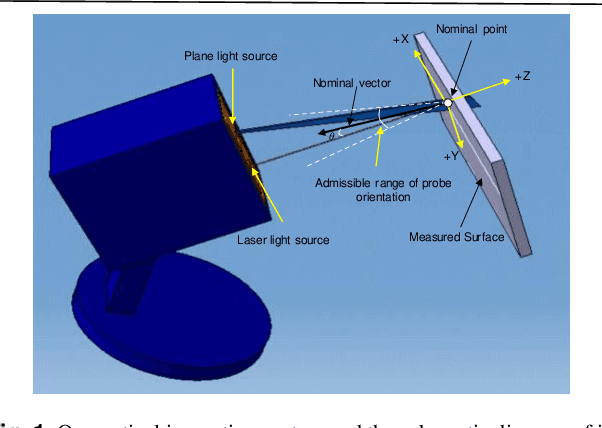

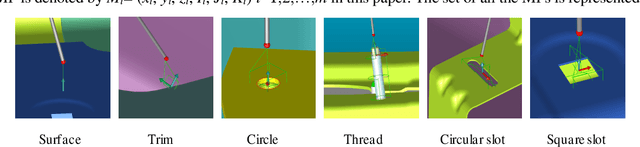

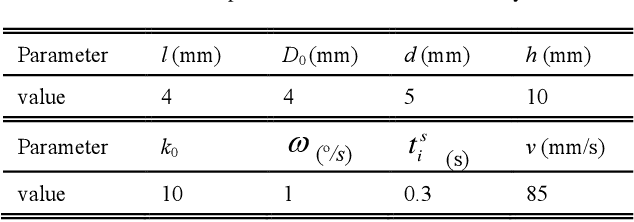

Abstract:The optical scanning gauges mounted on the robots are commonly used in quality inspection, such as verifying the dimensional specification of sheet structures. Coverage path planning (CPP) significantly influences the accuracy and efficiency of robotic quality inspection. Traditional CPP strategies focus on minimizing the number of viewpoints or traveling distance of robots under the condition of full coverage inspection. The measurement uncertainty when collecting the scanning data is less considered in the free-form surface inspection. To address this problem, a novel CPP method with the optimal viewpoint sampling strategy is proposed to incorporate the measurement uncertainty of key measurement points (MPs) into free-form surface inspection. At first, the feasible ranges of measurement uncertainty are calculated based on the tolerance specifications of the MPs. The initial feasible viewpoint set is generated considering the measurement uncertainty and the visibility of MPs. Then, the inspection cost function is built to evaluate the number of selected viewpoints and the average measurement uncertainty in the field of views (FOVs) of all the selected viewpoints. Afterward, an enhanced rapidly-exploring random tree (RRT*) algorithm is proposed for viewpoint sampling using the inspection cost function and CPP optimization. Case studies, including simulation tests and inspection experiments, have been conducted to evaluate the effectiveness of the proposed method. Results show that the scanning precision of key MPs is significantly improved compared with the benchmark method.

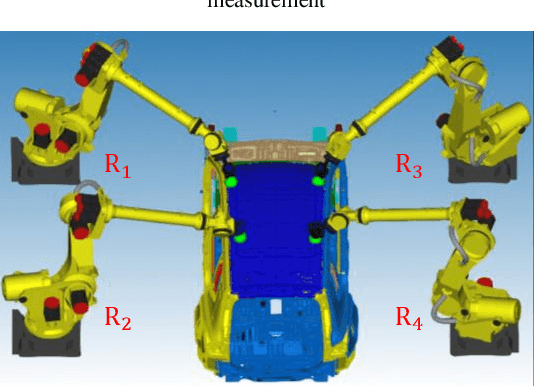

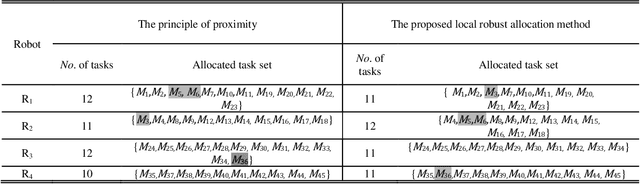

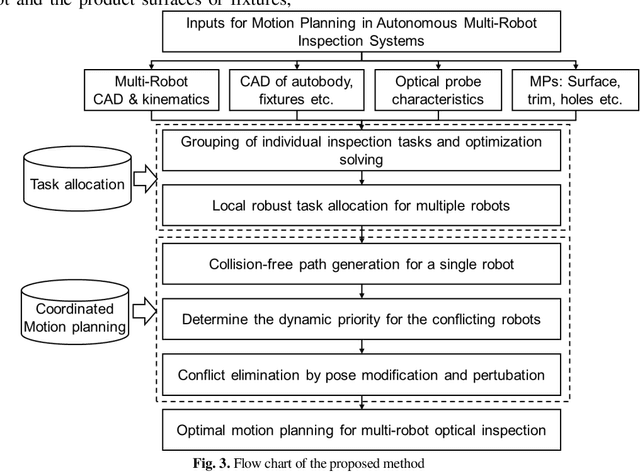

Task Allocation and Coordinated Motion Planning for Autonomous Multi-Robot Optical Inspection Systems

Jun 15, 2021

Abstract:Autonomous multi-robot optical inspection systems are increasingly applied for obtaining inline measurements in process monitoring and quality control. Numerous methods for path planning and robotic coordination have been developed for static and dynamic environments and applied to different fields. However, these approaches may not work for the autonomous multi-robot optical inspection system due to fast computation requirements of inline optimization, unique characteristics on robotic end-effector orientations, and complex large-scale free-form product surfaces. This paper proposes a novel task allocation methodology for coordinated motion planning of multi-robot inspection. Specifically, (1) a local robust inspection task allocation is proposed to achieve efficient and well-balanced measurement assignment among robots; (2) collision-free path planning and coordinated motion planning are developed via dynamic searching in robotic coordinate space and perturbation of probe poses or local paths in the conflicting robots. A case study shows that the proposed approach can mitigate the risk of collisions between robots and environments, resolve conflicts among robots, and reduce the inspection cycle time significantly and consistently.

Optimal Path Planning for Automated Dimensional Inspection of Free-Form Surfaces

May 15, 2020

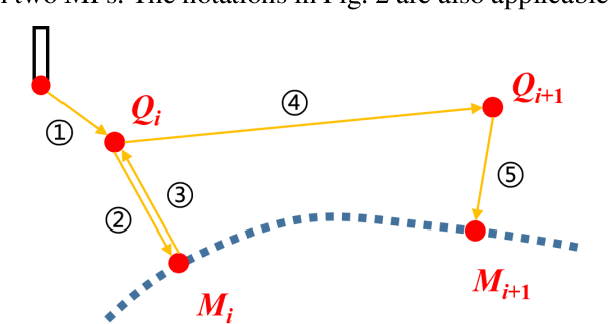

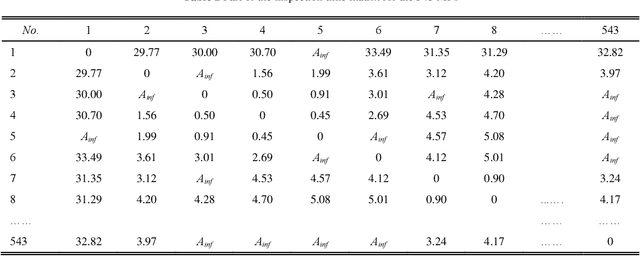

Abstract:Structural dimensional inspection is vital for the process monitoring, quality control, and fault diagnosis in the mass production of auto bodies. Comparing with the non-contact measurement, the high-precision five-axis measuring machine with the touch-trigger probe is a preferred choice for data collection. It can assist manufacturers in making accurate inspection quickly. As the increase of free-form surfaces and diverse surface orientations in auto body design, existing inspection approaches cannot capture some new critical features in the curvature of auto bodies in an efficient way. Therefore, we need to develop new path planning methods for automated dimensional inspection of free-form surfaces. This paper proposes an optimal path planning system for automated programming of measuring point inspection by incorporating probe rotations and effective collision detection. Specifically, the methodological contributions include: (i) a dynamic searching volume-based algorithm is developed to detect potential collisions in the local path between measurement points; (ii) a local path generation method is proposed with the integration of the probe trajectory and the stylus rotation. Then, the inspection time matrix is proposed to quantify the measuring time of diverse local paths; (iii) an optimization approach of the global inspection path for all critical points on the auto body is developed to minimize the total inspection time. A case study has been conducted on an auto body to verify the performance of the proposed method. Results show that the collision-free path for the free-form auto body could be generated automatically with off-line programming, and the proposed method produces about 40% fewer dummy points and needs 32% less movement time in the auto body inspection process.

Add to Chrome

Add to Chrome Add to Firefox

Add to Firefox Add to Edge

Add to Edge