Optimal Path Planning for Automated Dimensional Inspection of Free-Form Surfaces

Paper and Code

May 15, 2020

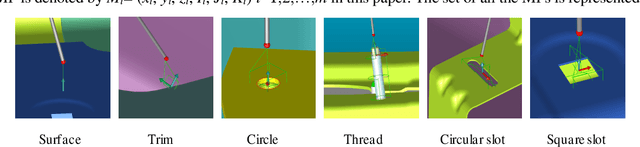

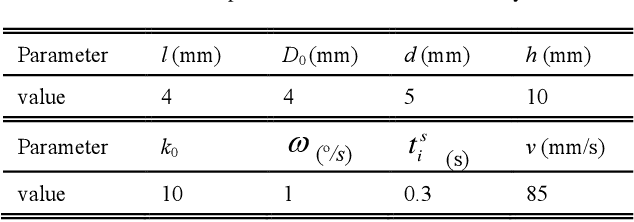

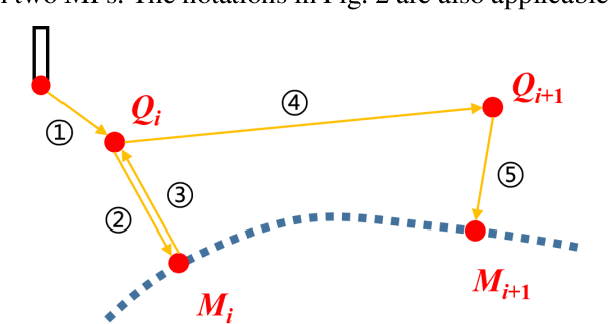

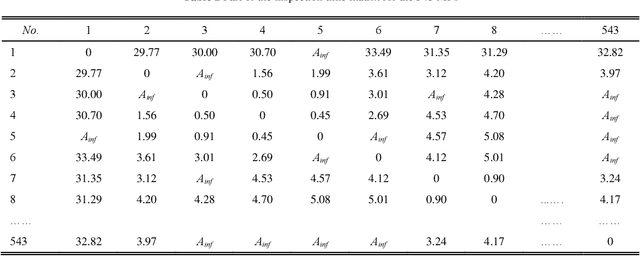

Structural dimensional inspection is vital for the process monitoring, quality control, and fault diagnosis in the mass production of auto bodies. Comparing with the non-contact measurement, the high-precision five-axis measuring machine with the touch-trigger probe is a preferred choice for data collection. It can assist manufacturers in making accurate inspection quickly. As the increase of free-form surfaces and diverse surface orientations in auto body design, existing inspection approaches cannot capture some new critical features in the curvature of auto bodies in an efficient way. Therefore, we need to develop new path planning methods for automated dimensional inspection of free-form surfaces. This paper proposes an optimal path planning system for automated programming of measuring point inspection by incorporating probe rotations and effective collision detection. Specifically, the methodological contributions include: (i) a dynamic searching volume-based algorithm is developed to detect potential collisions in the local path between measurement points; (ii) a local path generation method is proposed with the integration of the probe trajectory and the stylus rotation. Then, the inspection time matrix is proposed to quantify the measuring time of diverse local paths; (iii) an optimization approach of the global inspection path for all critical points on the auto body is developed to minimize the total inspection time. A case study has been conducted on an auto body to verify the performance of the proposed method. Results show that the collision-free path for the free-form auto body could be generated automatically with off-line programming, and the proposed method produces about 40% fewer dummy points and needs 32% less movement time in the auto body inspection process.

Add to Chrome

Add to Chrome Add to Firefox

Add to Firefox Add to Edge

Add to Edge