Yi-Shiuan Tung

Workspace Optimization Techniques to Improve Prediction of Human Motion During Human-Robot Collaboration

Jan 23, 2024

Abstract:Understanding human intentions is critical for safe and effective human-robot collaboration. While state of the art methods for human goal prediction utilize learned models to account for the uncertainty of human motion data, that data is inherently stochastic and high variance, hindering those models' utility for interactions requiring coordination, including safety-critical or close-proximity tasks. Our key insight is that robot teammates can deliberately configure shared workspaces prior to interaction in order to reduce the variance in human motion, realizing classifier-agnostic improvements in goal prediction. In this work, we present an algorithmic approach for a robot to arrange physical objects and project "virtual obstacles" using augmented reality in shared human-robot workspaces, optimizing for human legibility over a given set of tasks. We compare our approach against other workspace arrangement strategies using two human-subjects studies, one in a virtual 2D navigation domain and the other in a live tabletop manipulation domain involving a robotic manipulator arm. We evaluate the accuracy of human motion prediction models learned from each condition, demonstrating that our workspace optimization technique with virtual obstacles leads to higher robot prediction accuracy using less training data.

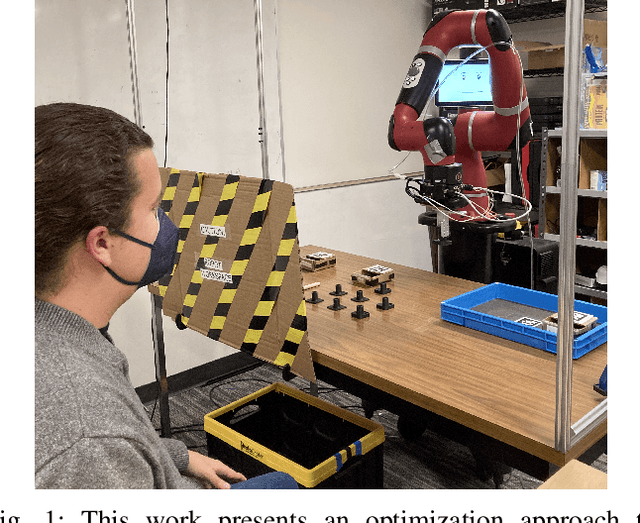

Improving Human Legibility in Collaborative Robot Tasks through Augmented Reality and Workspace Preparation

Nov 09, 2023

Abstract:Understanding the intentions of human teammates is critical for safe and effective human-robot interaction. The canonical approach for human-aware robot motion planning is to first predict the human's goal or path, and then construct a robot plan that avoids collision with the human. This method can generate unsafe interactions if the human model and subsequent predictions are inaccurate. In this work, we present an algorithmic approach for both arranging the configuration of objects in a shared human-robot workspace, and projecting ``virtual obstacles'' in augmented reality, optimizing for legibility in a given task. These changes to the workspace result in more legible human behavior, improving robot predictions of human goals, thereby improving task fluency and safety. To evaluate our approach, we propose two user studies involving a collaborative tabletop task with a manipulator robot, and a warehouse navigation task with a mobile robot.

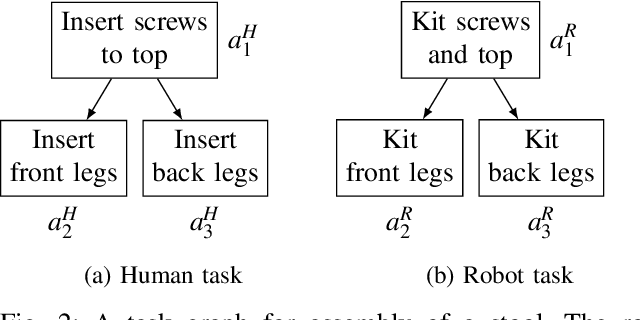

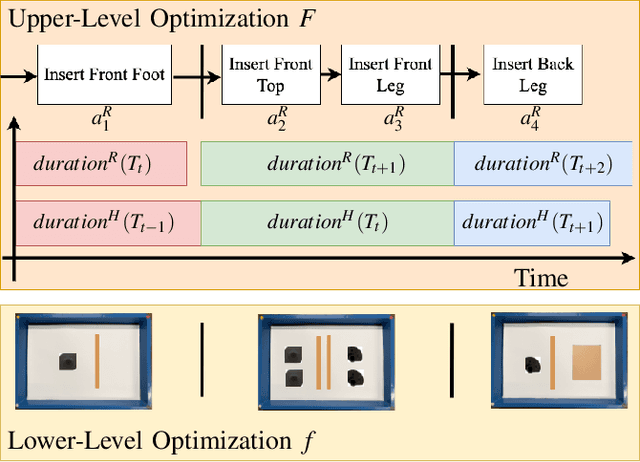

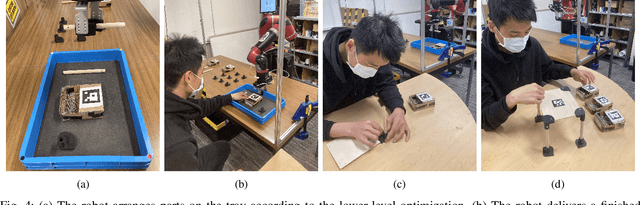

Bilevel Optimization for Just-in-Time Robotic Kitting and Delivery via Adaptive Task Segmentation and Scheduling

Sep 17, 2022

Abstract:Kitting refers to the task of preparing and grouping necessary parts and tools (or "kits") for assembly in a manufacturing environment. Automating this process simplifies the assembly task for human workers and improves efficiency. Existing automated kitting systems adhere to scripted instructions and predefined heuristics. However, given variability in the availability of parts and logistic delays, the inflexibility of existing systems can limit the overall efficiency of an assembly line. In this paper, we propose a bilevel optimization framework to enable a robot to perform task segmentation-based part selection, kit arrangement, and delivery scheduling to provide custom-tailored kits just in time - i.e., right when they are needed. We evaluate the proposed approach both through a human subjects study (n=18) involving the construction of a flat-pack furniture table and shop-flow simulation based on the data from the study. Our results show that the just-in-time kitting system is objectively more efficient, resilient to upstream shop flow delays, and subjectively more preferable as compared to baseline approaches of using kits defined by rigid task segmentation boundaries defined by the task graph itself or a single kit that includes all parts necessary to assemble a single unit.

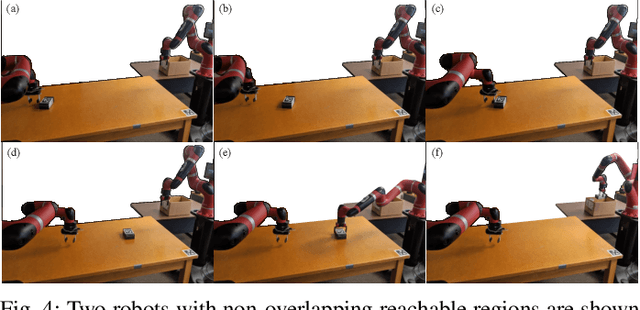

PokeRRT: A Kinodynamic Planning Approach for Poking Manipulation

Feb 09, 2022

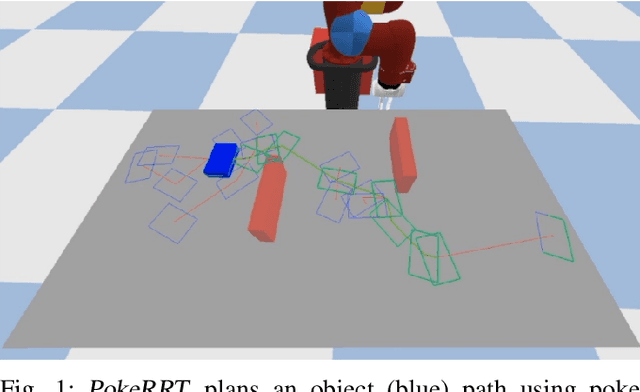

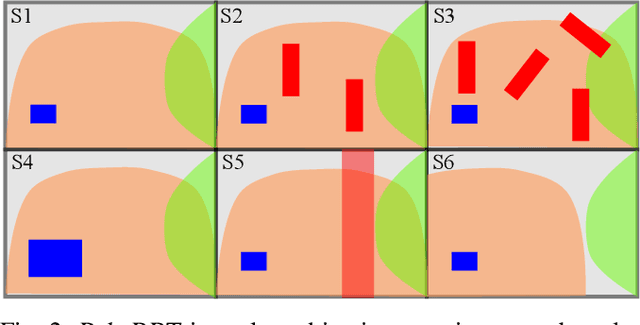

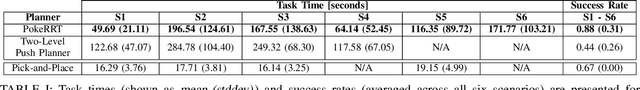

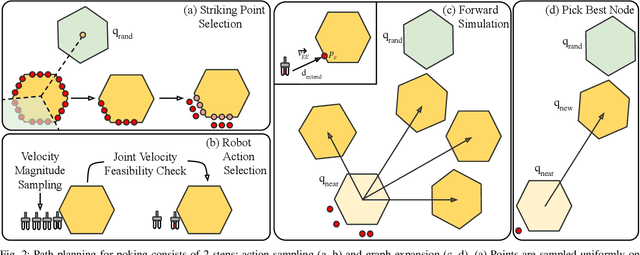

Abstract:This work introduces PokeRRT, a novel motion planning algorithm that demonstrates poking as an effective non-prehensile manipulation skill to enable fast manipulation of objects and increase the size of a robot's reachable workspace. Our qualitative and quantitative results demonstrate the advantages of poking over pushing and grasping in planning object trajectories through uncluttered and cluttered environments.

PokeRRT: Poking as a Skill and Failure Recovery Tactic for Planar Non-Prehensile Manipulation

Jan 31, 2022

Abstract:In this work, we introduce PokeRRT, a novel motion planning algorithm that demonstrates poking as an effective non-prehensile manipulation skill to enable fast manipulation of objects and increase the size of a robot's reachable workspace. We showcase poking as a failure recovery tactic used synergistically with pick-and-place for resiliency in cases where pick-and-place initially fails or is unachievable. Our experiments demonstrate the efficiency of the proposed framework in planning object trajectories using poking manipulation in uncluttered and cluttered environments. In addition to quantitatively and qualitatively demonstrating the adaptability of PokeRRT to different scenarios in both simulation and real-world settings, our results show the advantages of poking over pushing and grasping in terms of success rate and task time.

Add to Chrome

Add to Chrome Add to Firefox

Add to Firefox Add to Edge

Add to Edge