Vitaliy Pozdnyakov

Binary Cumulative Encoding meets Time Series Forecasting

May 30, 2025Abstract:Recent studies in time series forecasting have explored formulating regression via classification task. By discretizing the continuous target space into bins and predicting over a fixed set of classes, these approaches benefit from stable training, robust uncertainty modeling, and compatibility with modern deep learning architectures. However, most existing methods rely on one-hot encoding that ignores the inherent ordinal structure of the underlying values. As a result, they fail to provide information about the relative distance between predicted and true values during training. In this paper, we propose to address this limitation by introducing binary cumulative encoding (BCE), that represents scalar targets into monotonic binary vectors. This encoding implicitly preserves order and magnitude information, allowing the model to learn distance-aware representations while still operating within a classification framework. We propose a convolutional neural network architecture specifically designed for BCE, incorporating residual and dilated convolutions to enable fast and expressive temporal modeling. Through extensive experiments on benchmark forecasting datasets, we show that our approach outperforms widely used methods in both point and probabilistic forecasting, while requiring fewer parameters and enabling faster training.

Adversarial Attacks and Defenses in Automated Control Systems: A Comprehensive Benchmark

Mar 21, 2024Abstract:Integrating machine learning into Automated Control Systems (ACS) enhances decision-making in industrial process management. One of the limitations to the widespread adoption of these technologies in industry is the vulnerability of neural networks to adversarial attacks. This study explores the threats in deploying deep learning models for fault diagnosis in ACS using the Tennessee Eastman Process dataset. By evaluating three neural networks with different architectures, we subject them to six types of adversarial attacks and explore five different defense methods. Our results highlight the strong vulnerability of models to adversarial samples and the varying effectiveness of defense strategies. We also propose a novel protection approach by combining multiple defense methods and demonstrate it's efficacy. This research contributes several insights into securing machine learning within ACS, ensuring robust fault diagnosis in industrial processes.

Graph Neural Networks with Trainable Adjacency Matrices for Fault Diagnosis on Multivariate Sensor Data

Oct 20, 2022

Abstract:Timely detected anomalies in the chemical technological processes, as well as the earliest detection of the cause of the fault, significantly reduce the production cost in the industrial factories. Data on the state of the technological process and the operation of production equipment are received by a large number of different sensors. To better predict the behavior of the process and equipment, it is necessary not only to consider the behavior of the signals in each sensor separately, but also to take into account their correlation and hidden relationships with each other. Graph-based data representation helps with this. The graph nodes can be represented as data from the different sensors, and the edges can display the influence of these data on each other. In this work, the possibility of applying graph neural networks to the problem of fault diagnosis in a chemical process is studied. It was proposed to construct a graph during the training of graph neural network. This allows to train models on data where the dependencies between the sensors are not known in advance. In this work, several methods for obtaining adjacency matrices were considered, as well as their quality was studied. It has also been proposed to use multiple adjacency matrices in one model. We showed state-of-the-art performance on the fault diagnosis task with the Tennessee Eastman Process dataset. The proposed graph neural networks outperformed the results of recurrent neural networks.

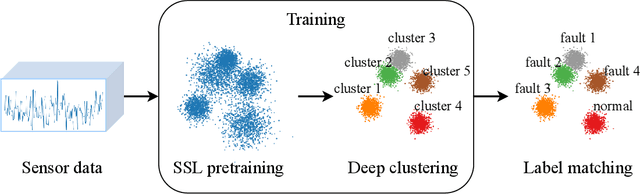

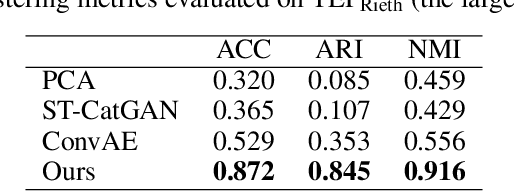

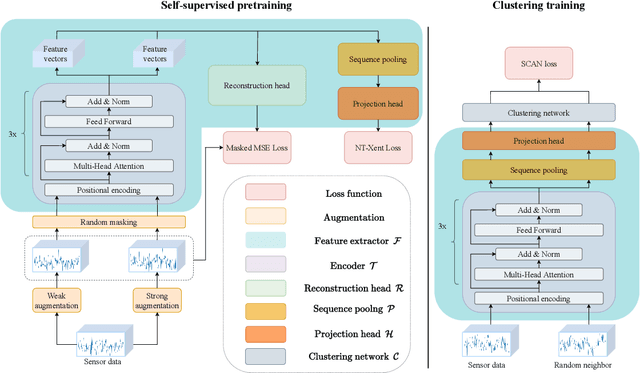

SensorSCAN: Self-Supervised Learning and Deep Clustering for Fault Diagnosis in Chemical Processes

Aug 17, 2022

Abstract:Modern industrial facilities generate large volumes of raw sensor data during production process. This data is used to monitor and control the processes and can be analyzed to detect and predict process abnormalities. Typically, the data has to be annotated by experts to be further used in predictive modeling. Most of today's research is focusing on either unsupervised anomaly detection algorithms or supervised methods, that require manually annotated data. The studies are often done using process simulator generated data for a narrow class of events and proposed algorithms are rarely verified on publicly available datasets. In this paper, we propose a novel method SensorSCAN for unsupervised fault detection and diagnosis designed for industrial chemical sensor data. We demonstrate our model performance on two publicly available datasets based on the Tennessee Eastman Process with various fault types. Results show that our method significantly outperforms existing approaches (+0.2-0.3 TPR for a fixed FPR) and detects most of the process faults without the use of expert annotation. In addition, we performed experiments to show that our method is suitable for real-world applications where the number of fault types is not known in advance.

Add to Chrome

Add to Chrome Add to Firefox

Add to Firefox Add to Edge

Add to Edge