Thomas Langerak

Cost-Aware Bayesian Optimization for Prototyping Interactive Devices

Feb 02, 2026Abstract:Deciding which idea is worth prototyping is a central concern in iterative design. A prototype should be produced when the expected improvement is high and the cost is low. However, this is hard to decide, because costs can vary drastically: a simple parameter tweak may take seconds, while fabricating hardware consumes material and energy. Such asymmetries, can discourage a designer from exploring the design space. In this paper, we present an extension of cost-aware Bayesian optimization to account for diverse prototyping costs. The method builds on the power of Bayesian optimization and requires only a minimal modification to the acquisition function. The key idea is to use designer-estimated costs to guide sampling toward more cost-effective prototypes. In technical evaluations, the method achieved comparable utility to a cost-agnostic baseline while requiring only ${\approx}70\%$ of the cost; under strict budgets, it outperformed the baseline threefold. A within-subjects study with 12 participants in a realistic joystick design task demonstrated similar benefits. These results show that accounting for prototyping costs can make Bayesian optimization more compatible with real-world design projects.

Robust Real-Time Tracking of Axis-Symmetric Magnets via Neural Networks

Nov 14, 2022

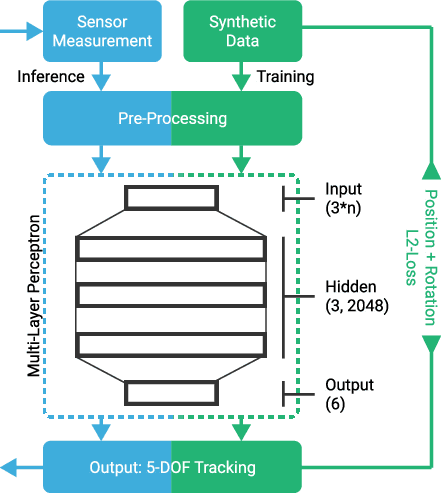

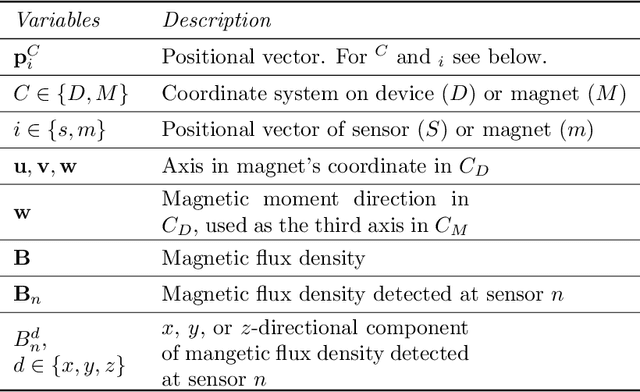

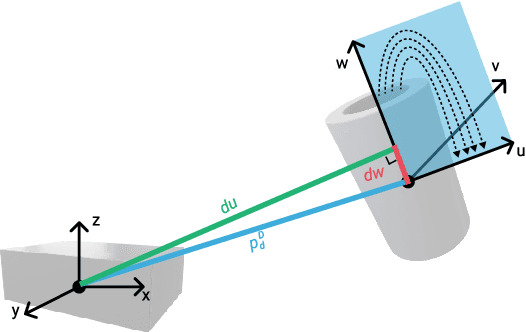

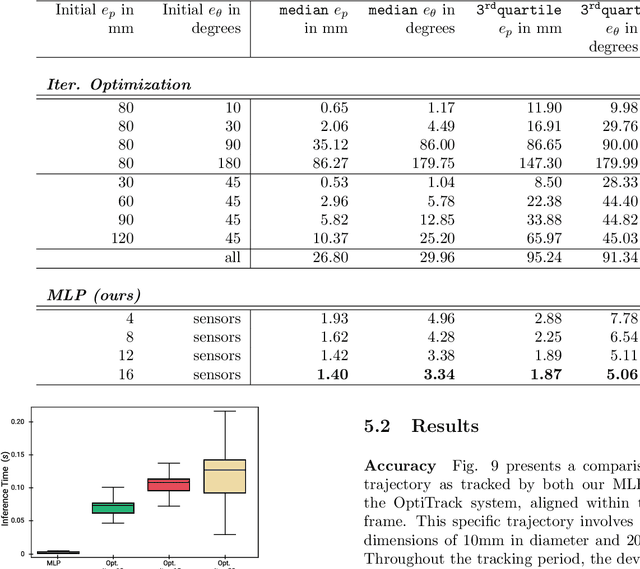

Abstract:Traditional tracking of magnetic markers leads to high computational costs due to the requirement for iterative optimization procedures. Furthermore, such approaches rely on the magnetic dipole model for the optimization function, leading to inaccurate results anytime a non-spherical magnet gets close to a sensor in the array. We propose to overcome these limitations by using neural networks to infer the marker's position and orientation. Our method can obtain the magnet's five degrees of freedom (5 DoF) in a single inference step without relying on an initial estimation. As a counterpart, the supervised training phase is data intensive. We solve this by generating synthetic, yet realistic, data via Finite Element Methods simulations. A fast and accurate inference largely compensates for the offline training preparation. We evaluate our system using different cylindrical magnets, tracked with a square array of 16 sensors. We use a portable, neural networks-oriented single-board computer for the sensors' reading and the position inference, making our setup very compact. We compared our tracking outputs with vision-based ground truth data. Our prototype implementation tracks $5$ DoF with an averaged positional error of 4mm and orientation error of 8deg within a 0.2x0.2x0.15m working volume.

Add to Chrome

Add to Chrome Add to Firefox

Add to Firefox Add to Edge

Add to Edge