Songjiang Lai

Enhancing Technical Documents Retrieval for RAG

Sep 04, 2025Abstract:In this paper, we introduce Technical-Embeddings, a novel framework designed to optimize semantic retrieval in technical documentation, with applications in both hardware and software development. Our approach addresses the challenges of understanding and retrieving complex technical content by leveraging the capabilities of Large Language Models (LLMs). First, we enhance user queries by generating expanded representations that better capture user intent and improve dataset diversity, thereby enriching the fine-tuning process for embedding models. Second, we apply summary extraction techniques to encode essential contextual information, refining the representation of technical documents. To further enhance retrieval performance, we fine-tune a bi-encoder BERT model using soft prompting, incorporating separate learning parameters for queries and document context to capture fine-grained semantic nuances. We evaluate our approach on two public datasets, RAG-EDA and Rust-Docs-QA, demonstrating that Technical-Embeddings significantly outperforms baseline models in both precision and recall. Our findings highlight the effectiveness of integrating query expansion and contextual summarization to enhance information access and comprehension in technical domains. This work advances the state of Retrieval-Augmented Generation (RAG) systems, offering new avenues for efficient and accurate technical document retrieval in engineering and product development workflows.

Automatic Prompt Generation and Grounding Object Detection for Zero-Shot Image Anomaly Detection

Nov 28, 2024

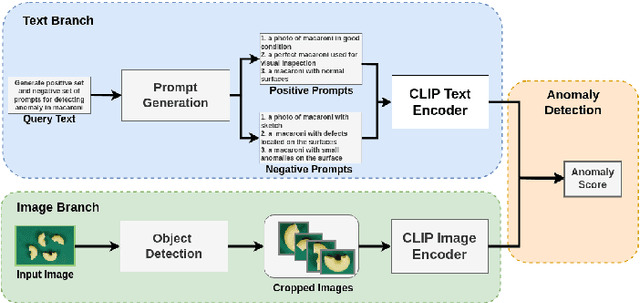

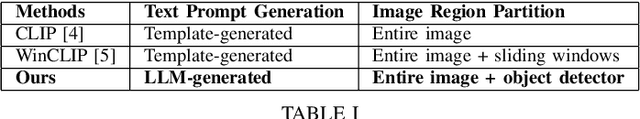

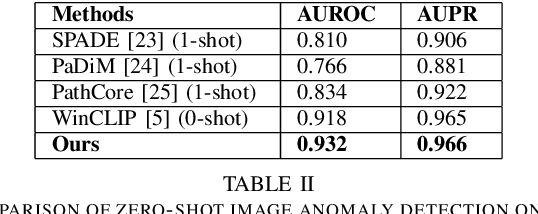

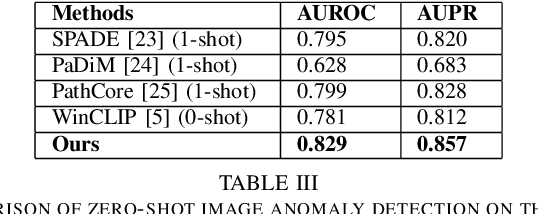

Abstract:Identifying defects and anomalies in industrial products is a critical quality control task. Traditional manual inspection methods are slow, subjective, and error-prone. In this work, we propose a novel zero-shot training-free approach for automated industrial image anomaly detection using a multimodal machine learning pipeline, consisting of three foundation models. Our method first uses a large language model, i.e., GPT-3. generate text prompts describing the expected appearances of normal and abnormal products. We then use a grounding object detection model, called Grounding DINO, to locate the product in the image. Finally, we compare the cropped product image patches to the generated prompts using a zero-shot image-text matching model, called CLIP, to identify any anomalies. Our experiments on two datasets of industrial product images, namely MVTec-AD and VisA, demonstrate the effectiveness of this method, achieving high accuracy in detecting various types of defects and anomalies without the need for model training. Our proposed model enables efficient, scalable, and objective quality control in industrial manufacturing settings.

Residual Attention Single-Head Vision Transformer Network for Rolling Bearing Fault Diagnosis in Noisy Environments

Nov 27, 2024

Abstract:Rolling bearings play a crucial role in industrial machinery, directly influencing equipment performance, durability, and safety. However, harsh operating conditions, such as high speeds and temperatures, often lead to bearing malfunctions, resulting in downtime, economic losses, and safety hazards. This paper proposes the Residual Attention Single-Head Vision Transformer Network (RA-SHViT-Net) for fault diagnosis in rolling bearings. Vibration signals are transformed from the time to frequency domain using the Fast Fourier Transform (FFT) before being processed by RA-SHViT-Net. The model employs the Single-Head Vision Transformer (SHViT) to capture local and global features, balancing computational efficiency and predictive accuracy. To enhance feature extraction, the Adaptive Hybrid Attention Block (AHAB) integrates channel and spatial attention mechanisms. The network architecture includes Depthwise Convolution, Single-Head Self-Attention, Residual Feed-Forward Networks (Res-FFN), and AHAB modules, ensuring robust feature representation and mitigating gradient vanishing issues. Evaluation on the Case Western Reserve University and Paderborn University datasets demonstrates the RA-SHViT-Net's superior accuracy and robustness in complex, noisy environments. Ablation studies further validate the contributions of individual components, establishing RA-SHViT-Net as an effective tool for early fault detection and classification, promoting efficient maintenance strategies in industrial settings. Keywords: rolling bearings, fault diagnosis, Vision Transformer, attention mechanism, noisy environments, Fast Fourier Transform (FFT)

CBAM-SwinT-BL: Small Rail Surface Detect Detection Method Based on Swin Transformer with Block Level CBAM Enhancement

Sep 30, 2024

Abstract:Under high-intensity rail operations, rail tracks endure considerable stresses resulting in various defects such as corrugation and spellings. Failure to effectively detect defects and provide maintenance in time would compromise service reliability and public safety. While advanced models have been developed in recent years, efficiently identifying small-scale rail defects has not yet been studied, especially for categories such as Dirt or Squat on rail surface. To address this challenge, this study utilizes Swin Transformer (SwinT) as baseline and incorporates the Convolutional Block Attention Module (CBAM) for enhancement. Our proposed method integrates CBAM successively within the swin transformer blocks, resulting in significant performance improvement in rail defect detection, particularly for categories with small instance sizes. The proposed framework is named CBAM-Enhanced Swin Transformer in Block Level (CBAM-SwinT-BL). Experiment and ablation study have proven the effectiveness of the framework. The proposed framework has a notable improvement in the accuracy of small size defects, such as dirt and dent categories in RIII dataset, with mAP-50 increasing by +23.0% and +38.3% respectively, and the squat category in MUET dataset also reaches +13.2% higher than the original model. Compares to the original SwinT, CBAM-SwinT-BL increase overall precision around +5% in the MUET dataset and +7% in the RIII dataset, reaching 69.1% and 88.1% respectively. Meanwhile, the additional module CBAM merely extend the model training speed by an average of +0.04s/iteration, which is acceptable compared to the significant improvement in system performance.

Add to Chrome

Add to Chrome Add to Firefox

Add to Firefox Add to Edge

Add to Edge