Singanallur Venkatakrishnan

2.5D Super-Resolution Approaches for X-ray Computed Tomography-based Inspection of Additively Manufactured Parts

Dec 05, 2024Abstract:X-ray computed tomography (XCT) is a key tool in non-destructive evaluation of additively manufactured (AM) parts, allowing for internal inspection and defect detection. Despite its widespread use, obtaining high-resolution CT scans can be extremely time consuming. This issue can be mitigated by performing scans at lower resolutions; however, reducing the resolution compromises spatial detail, limiting the accuracy of defect detection. Super-resolution algorithms offer a promising solution for overcoming resolution limitations in XCT reconstructions of AM parts, enabling more accurate detection of defects. While 2D super-resolution methods have demonstrated state-of-the-art performance on natural images, they tend to under-perform when directly applied to XCT slices. On the other hand, 3D super-resolution methods are computationally expensive, making them infeasible for large-scale applications. To address these challenges, we propose a 2.5D super-resolution approach tailored for XCT of AM parts. Our method enhances the resolution of individual slices by leveraging multi-slice information from neighboring 2D slices without the significant computational overhead of full 3D methods. Specifically, we use neighboring low-resolution slices to super-resolve the center slice, exploiting inter-slice spatial context while maintaining computational efficiency. This approach bridges the gap between 2D and 3D methods, offering a practical solution for high-throughput defect detection in AM parts.

Edge Projection-Based Adaptive View Selection for Cone-Beam CT

Jul 17, 2024

Abstract:Industrial cone-beam X-ray computed tomography (CT) scans of additively manufactured components produce a 3D reconstruction from projection measurements acquired at multiple predetermined rotation angles of the component about a single axis. Typically, a large number of projections are required to achieve a high-quality reconstruction, a process that can span several hours or days depending on the part size, material composition, and desired resolution. This paper introduces a novel real-time system designed to optimize the scanning process by intelligently selecting the best next angle based on the object's geometry and computer-aided design (CAD) model. This selection process strategically balances the need for measurements aligned with the part's long edges against the need for maintaining a diverse set of overall measurements. Through simulations, we demonstrate that our algorithm significantly reduces the number of projections needed to achieve high-quality reconstructions compared to traditional methods.

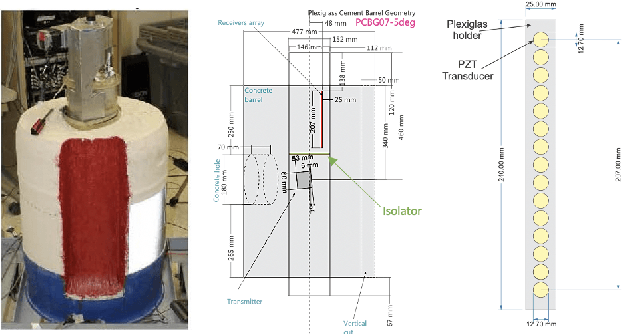

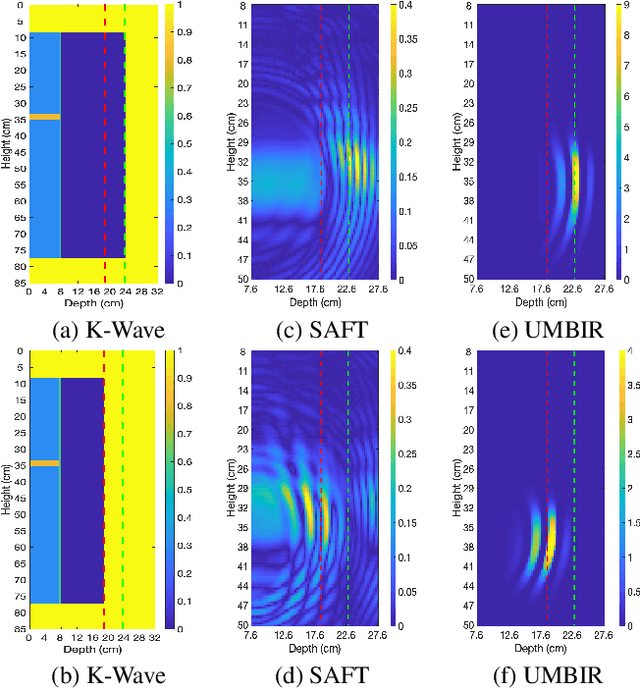

Ringing Artifact Reduction Method for Ultrasound Reconstruction Using Multi-Agent Consensus Equilibrium

Feb 09, 2023Abstract:Non-destructive characterization of multi-layered structures that can be accessed from only a single side is important for applications such as well-bore integrity inspection. Existing methods related to Synthetic Aperture Focusing Technique (SAFT) rapidly produce acceptable results but with significant artifacts. Recently, ultrasound model-based iterative reconstruction (UMBIR) approaches have shown significant improvements over SAFT. However, even these methods produce ringing artifacts due to the high fractional-bandwidth of the excitation signal. In this paper, we propose a ringing artifact reduction method for ultrasound image reconstruction that uses a multi-agent consensus equilibrium (RARE-MACE) framework. Our approach integrates a physics-based forward model that accounts for the propagation of a collimated ultrasonic beam in multi-layered media, a spatially varying image prior, and a denoiser designed to suppress the ringing artifacts that are characteristic of reconstructions from high-fractional bandwidth ultrasound sensor data. We test our method on simulated and experimental measurements and show substantial improvements in image quality compared to SAFT and UMBIR.

Model-based Reconstruction for Multi-Frequency Collimated Beam Ultrasound Systems

Nov 29, 2022Abstract:Collimated beam ultrasound systems are a technology for imaging inside multi-layered structures such as geothermal wells. These systems work by using a collimated narrow-band ultrasound transmitter that can penetrate through multiple layers of heterogeneous material. A series of measurements can then be made at multiple transmit frequencies. However, commonly used reconstruction algorithms such as Synthetic Aperture Focusing Technique (SAFT) tend to produce poor quality reconstructions for these systems both because they do not model collimated beam systems and they do not jointly reconstruct the multiple frequencies. In this paper, we propose a multi-frequency ultrasound model-based iterative reconstruction (UMBIR) algorithm designed for multi-frequency collimated beam ultrasound systems. The combined system targets reflective imaging of heterogeneous, multi-layered structures. For each transmitted frequency band, we introduce a physics-based forward model to accurately account for the propagation of the collimated narrow-band ultrasonic beam through the multi-layered media. We then show how the joint multi-frequency UMBIR reconstruction can be computed by modeling the direct arrival signals, detector noise, and incorporating a spatially varying image prior. Results using both simulated and experimental data indicate that multi-frequency UMBIR reconstruction yields much higher reconstruction quality than either single frequency UMBIR or SAFT.

Model-Based Reconstruction for Collimated Beam Ultrasound Systems

Feb 20, 2022

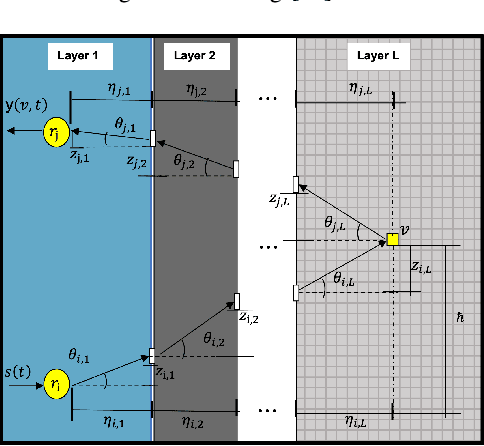

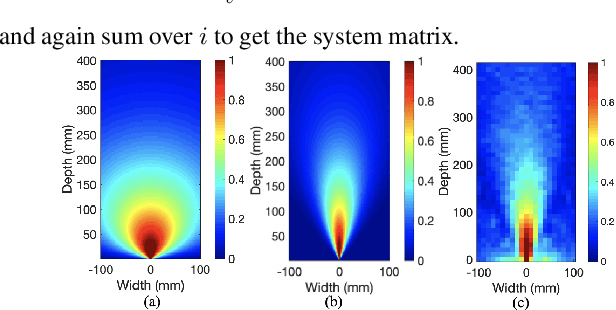

Abstract:Collimated beam ultrasound systems are a novel technology for imaging inside multi-layered structures such as geothermal wells. Such systems include a transmitter and multiple receivers to capture reflected signals. Common algorithms for ultrasound reconstruction use delay-and-sum (DAS) approaches; these have low computational complexity but produce inaccurate images in the presence of complex structures and specialized geometries such as collimated beams. In this paper, we propose a multi-layer, ultrasonic, model-based iterative reconstruction algorithm designed for collimated beam systems. We introduce a physics-based forward model to accurately account for the propagation of a collimated ultrasonic beam in multi-layer media and describe an efficient implementation using binary search. We model direct arrival signals, detector noise, and a spatially varying image prior, then cast the reconstruction as a maximum a posteriori estimation problem. Using simulated and experimental data we obtain significantly fewer artifacts relative to DAS while running in near real time using commodity compute resources.

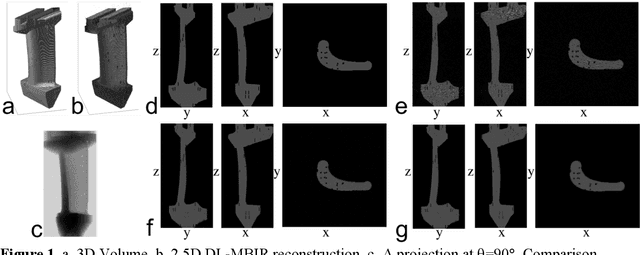

X-Ray CT Reconstruction of Additively Manufactured Parts using 2.5D Deep Learning MBIR

May 06, 2019

Abstract:In this paper, we present a deep learning algorithm to rapidly obtain high quality CT reconstructions for AM parts. In particular, we propose to use CAD models of the parts that are to be manufactured, introduce typical defects and simulate XCT measurements. These simulated measurements were processed using FBP (computationally simple but result in noisy images) and the MBIR technique. We then train a 2.5D deep convolutional neural network [4], deemed 2.5D Deep Learning MBIR (2.5D DL-MBIR), on these pairs of noisy and high-quality 3D volumes to learn a fast, non-linear mapping function. The 2.5D DL-MBIR reconstructs a 3D volume in a 2.5D scheme where each slice is reconstructed from multiple inputs slices of the FBP input. Given this trained system, we can take a small set of measurements on an actual part, process it using a combination of FBP followed by 2.5D DL-MBIR. Both steps can be rapidly performed using GPUs, resulting in a real-time algorithm that achieves the high-quality of MBIR as fast as standard techniques. Intuitively, since CAD models are typically available for parts to be manufactured, this provides a strong constraint "prior" which can be leveraged to improve the reconstruction.

Add to Chrome

Add to Chrome Add to Firefox

Add to Firefox Add to Edge

Add to Edge