Simon Baeuerle

Rapid AI-based generation of coverage paths for dispensing applications

May 06, 2025

Abstract:Coverage Path Planning of Thermal Interface Materials (TIM) plays a crucial role in the design of power electronics and electronic control units. Up to now, this is done manually by experts or by using optimization approaches with a high computational effort. We propose a novel AI-based approach to generate dispense paths for TIM and similar dispensing applications. It is a drop-in replacement for optimization-based approaches. An Artificial Neural Network (ANN) receives the target cooling area as input and directly outputs the dispense path. Our proposed setup does not require labels and we show its feasibility on multiple target areas. The resulting dispense paths can be directly transferred to automated manufacturing equipment and do not exhibit air entrapments. The approach of using an ANN to predict process parameters for a desired target state in real-time could potentially be transferred to other manufacturing processes.

Coverage Path Planning for Thermal Interface Materials

May 22, 2024

Abstract:Thermal management of power electronics and Electronic Control Units is crucial in times of increasing power densities and limited assembly space. Electric and autonomous vehicles are a prominent application field. Thermal Interface Materials are used to transfer heat from a semiconductor to a heatsink. They are applied along a dispense path onto the semiconductor and spread over its entire surface once the heatsink is joined. To plan this application path, design engineers typically perform an iterative trial-and-error procedure of elaborate simulations and manual experiments. We propose a fully automated optimization approach, which clearly outperforms the current manual path planning and respects all relevant manufacturing constraints. An optimum dispense path increases the reliability of the thermal interface and makes the manufacturing more sustainable by reducing material waste. We show results on multiple real products from automotive series production, including an experimental validation on actual series manufacturing equipment.

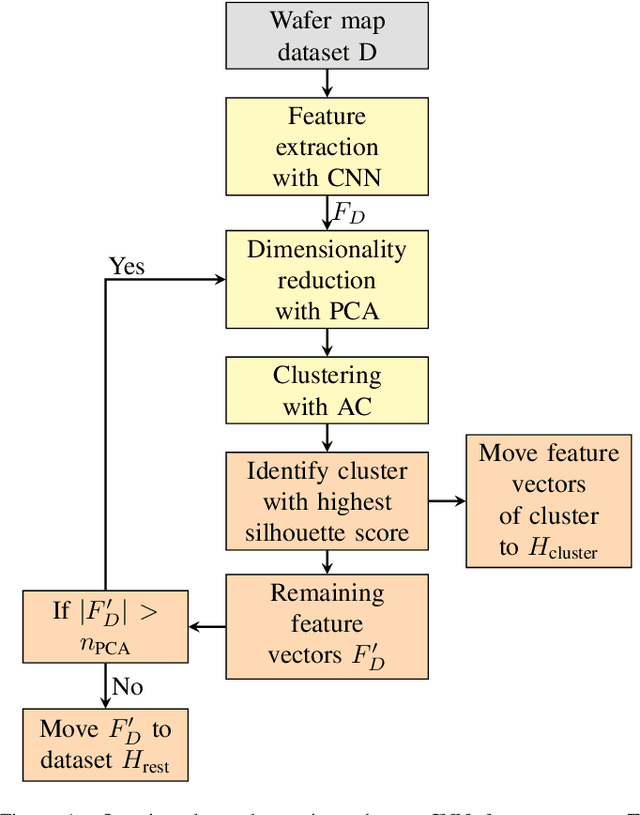

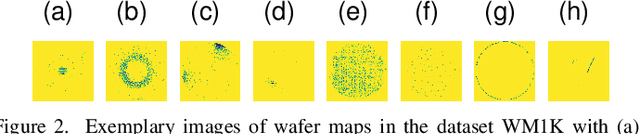

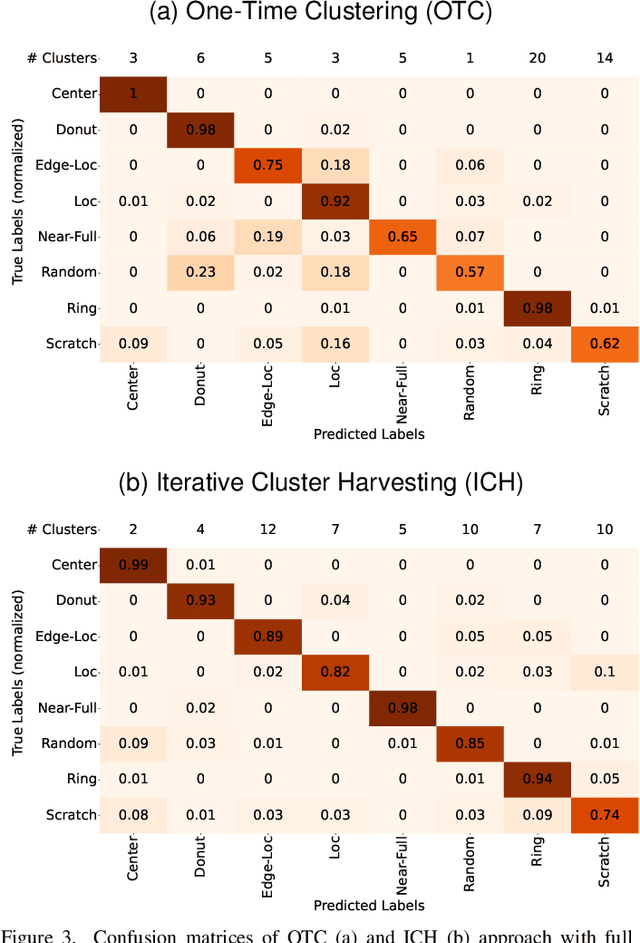

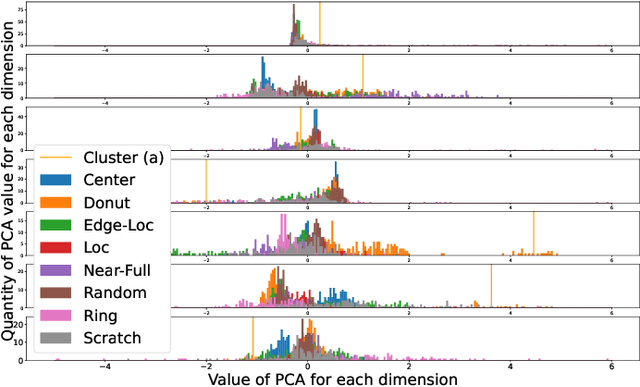

Iterative Cluster Harvesting for Wafer Map Defect Patterns

Apr 23, 2024

Abstract:Unsupervised clustering of wafer map defect patterns is challenging because the appearance of certain defect patterns varies significantly. This includes changing shape, location, density, and rotation of the defect area on the wafer. We present a harvesting approach, which can cluster even challenging defect patterns of wafer maps well. Our approach makes use of a well-known, three-step procedure: feature extraction, dimension reduction, and clustering. The novelty in our approach lies in repeating dimensionality reduction and clustering iteratively while filtering out one cluster per iteration according to its silhouette score. This method leads to an improvement of clustering performance in general and is especially useful for difficult defect patterns. The low computational effort allows for a quick assessment of large datasets and can be used to support manual labeling efforts. We benchmark against related approaches from the literature and show improved results on a real-world industrial dataset.

MLOps for Scarce Image Data: A Use Case in Microscopic Image Analysis

Oct 04, 2023Abstract:Nowadays, Machine Learning (ML) is experiencing tremendous popularity that has never been seen before. The operationalization of ML models is governed by a set of concepts and methods referred to as Machine Learning Operations (MLOps). Nevertheless, researchers, as well as professionals, often focus more on the automation aspect and neglect the continuous deployment and monitoring aspects of MLOps. As a result, there is a lack of continuous learning through the flow of feedback from production to development, causing unexpected model deterioration over time due to concept drifts, particularly when dealing with scarce data. This work explores the complete application of MLOps in the context of scarce data analysis. The paper proposes a new holistic approach to enhance biomedical image analysis. Our method includes: a fingerprinting process that enables selecting the best models, datasets, and model development strategy relative to the image analysis task at hand; an automated model development stage; and a continuous deployment and monitoring process to ensure continuous learning. For preliminary results, we perform a proof of concept for fingerprinting in microscopic image datasets.

Rapid Flow Behavior Modeling of Thermal Interface Materials Using Deep Neural Networks

Aug 09, 2022

Abstract:Thermal Interface Materials (TIMs) are widely used in electronic packaging. Increasing power density and limited assembly space pose high demands on thermal management. Large cooling surfaces need to be covered efficiently. When joining the heatsink, previously dispensed TIM spreads over the cooling surface. Recommendations on the dispensing pattern exist only for simple surface geometries such as rectangles. For more complex geometries, Computational Fluid Dynamics (CFD) simulations are used in combination with manual experiments. While CFD simulations offer a high accuracy, they involve simulation experts and are rather expensive to set up. We propose a lightweight heuristic to model the spreading behavior of TIM. We further speed up the calculation by training an Artificial Neural Network (ANN) on data from this model. This offers rapid computation times and further supplies gradient information. This ANN can not only be used to aid manual pattern design of TIM, but also enables an automated pattern optimization. We compare this approach against the state-of-the-art and use real product samples for validation.

CAD2Real: Deep learning with domain randomization of CAD data for 3D pose estimation of electronic control unit housings

Sep 25, 2020

Abstract:Electronic control units (ECUs) are essential for many automobile components, e.g. engine, anti-lock braking system (ABS), steering and airbags. For some products, the 3D pose of each single ECU needs to be determined during series production. Deep learning approaches can not easily be applied to this problem, because labeled training data is not available in sufficient numbers. Thus, we train state-of-the-art artificial neural networks (ANNs) on purely synthetic training data, which is automatically created from a single CAD file. By randomizing parameters during rendering of training images, we enable inference on RGB images of a real sample part. In contrast to classic image processing approaches, this data-driven approach poses only few requirements regarding the measurement setup and transfers to related use cases with little development effort.

Add to Chrome

Add to Chrome Add to Firefox

Add to Firefox Add to Edge

Add to Edge