Shoaib Aslam

GFT: Gradient Focal Transformer

Apr 14, 2025

Abstract:Fine-Grained Image Classification (FGIC) remains a complex task in computer vision, as it requires models to distinguish between categories with subtle localized visual differences. Well-studied CNN-based models, while strong in local feature extraction, often fail to capture the global context required for fine-grained recognition, while more recent ViT-backboned models address FGIC with attention-driven mechanisms but lack the ability to adaptively focus on truly discriminative regions. TransFG and other ViT-based extensions introduced part-aware token selection to enhance attention localization, yet they still struggle with computational efficiency, attention region selection flexibility, and detail-focus narrative in complex environments. This paper introduces GFT (Gradient Focal Transformer), a new ViT-derived framework created for FGIC tasks. GFT integrates the Gradient Attention Learning Alignment (GALA) mechanism to dynamically prioritize class-discriminative features by analyzing attention gradient flow. Coupled with a Progressive Patch Selection (PPS) strategy, the model progressively filters out less informative regions, reducing computational overhead while enhancing sensitivity to fine details. GFT achieves SOTA accuracy on FGVC Aircraft, Food-101, and COCO datasets with 93M parameters, outperforming ViT-based advanced FGIC models in efficiency. By bridging global context and localized detail extraction, GFT sets a new benchmark in fine-grained recognition, offering interpretable solutions for real-world deployment scenarios.

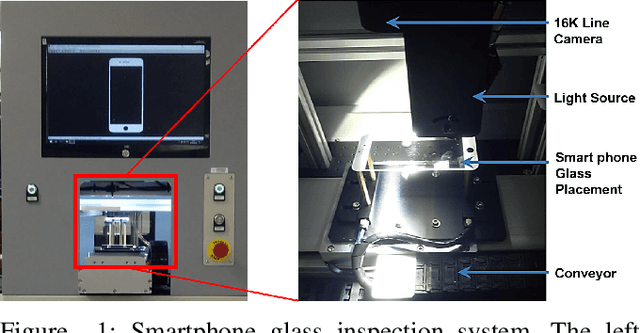

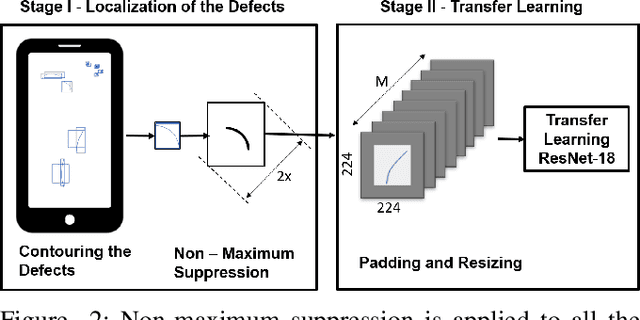

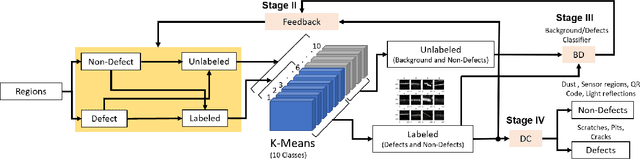

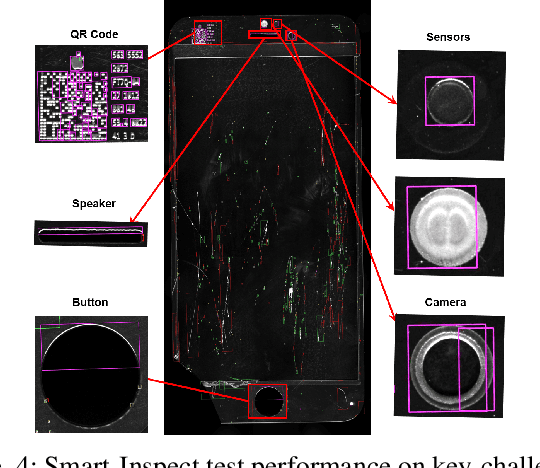

Smart-Inspect: Micro Scale Localization and Classification of Smartphone Glass Defects for Industrial Automation

Oct 02, 2020

Abstract:The presence of any type of defect on the glass screen of smart devices has a great impact on their quality. We present a robust semi-supervised learning framework for intelligent micro-scaled localization and classification of defects on a 16K pixel image of smartphone glass. Our model features the efficient recognition and labeling of three types of defects: scratches, light leakage due to cracks, and pits. Our method also differentiates between the defects and light reflections due to dust particles and sensor regions, which are classified as non-defect areas. We use a partially labeled dataset to achieve high robustness and excellent classification of defect and non-defect areas as compared to principal components analysis (PCA), multi-resolution and information-fusion-based algorithms. In addition, we incorporated two classifiers at different stages of our inspection framework for labeling and refining the unlabeled defects. We successfully enhanced the inspection depth-limit up to 5 microns. The experimental results show that our method outperforms manual inspection in testing the quality of glass screen samples by identifying defects on samples that have been marked as good by human inspection.

Add to Chrome

Add to Chrome Add to Firefox

Add to Firefox Add to Edge

Add to Edge