Raffaello Lepratti

On Event-Driven Knowledge Graph Completion in Digital Factories

Sep 08, 2021

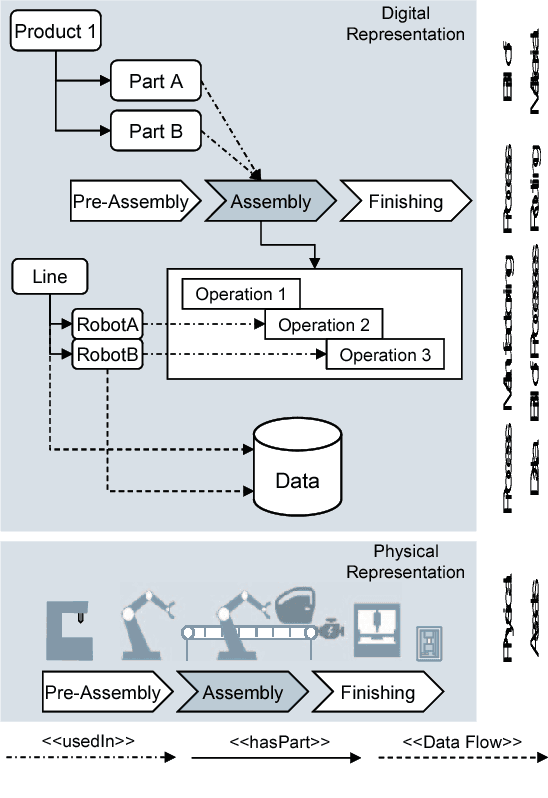

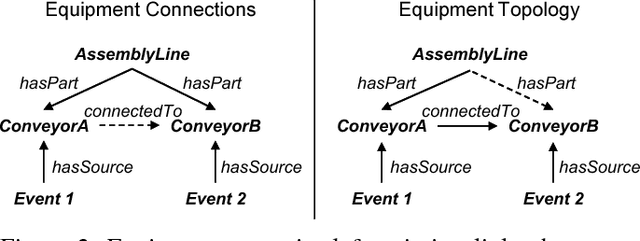

Abstract:Smart factories are equipped with machines that can sense their manufacturing environments, interact with each other, and control production processes. Smooth operation of such factories requires that the machines and engineering personnel that conduct their monitoring and diagnostics share a detailed common industrial knowledge about the factory, e.g., in the form of knowledge graphs. Creation and maintenance of such knowledge is expensive and requires automation. In this work we show how machine learning that is specifically tailored towards industrial applications can help in knowledge graph completion. In particular, we show how knowledge completion can benefit from event logs that are common in smart factories. We evaluate this on the knowledge graph from a real world-inspired smart factory with encouraging results.

Context-Aware Analytics in MOM Applications

Dec 26, 2014

Abstract:Manufacturing Operations Management (MOM) systems are complex in the sense that they integrate data from heterogeneous systems inside the automation pyramid. The need for context-aware analytics arises from the dynamics of these systems that influence data generation and hamper comparability of analytics, especially predictive models (e.g. predictive maintenance), where concept drift affects application of these models in the future. Recently, an increasing amount of research has been directed towards data integration using semantic context models. Manual construction of such context models is an elaborate and error-prone task. Therefore, we pose the challenge to apply combinations of knowledge extraction techniques in the domain of analytics in MOM, which comprises the scope of data integration within Product Life-cycle Management (PLM), Enterprise Resource Planning (ERP), and Manufacturing Execution Systems (MES). We describe motivations, technological challenges and show benefits of context-aware analytics, which leverage from and regard the interconnectedness of semantic context data. Our example scenario shows the need for distribution and effective change tracking of context information.

Add to Chrome

Add to Chrome Add to Firefox

Add to Firefox Add to Edge

Add to Edge