Petar Durdevic

STDiff: A State Transition Diffusion Framework for Time Series Imputation in Industrial Systems

Aug 28, 2025Abstract:Most deep learning methods for imputing missing values treat the task as completing patterns within a fixed time window. This assumption often fails in industrial systems, where dynamics are driven by control actions, are highly non-stationary, and can experience long, uninterrupted gaps. We propose STDiff, which reframes imputation as learning how the system evolves from one state to the next. STDiff uses a conditional denoising diffusion model with a causal bias aligned to control theory, generating missing values step-by-step based on the most recent known state and relevant control or environmental inputs. On a public wastewater treatment dataset with simulated missing blocks, STDiff consistently achieves the lowest errors, with its advantage increasing for longer gaps. On a raw industrial dataset with substantial real gaps, it produces trajectories that remain dynamically plausible, in contrast to window-based models that tend to flatten or over-smooth. These results support dynamics-aware, explicitly conditioned imputation as a robust approach for industrial time series, and we discuss computational trade-offs and extensions to broader domains.

FungalZSL: Zero-Shot Fungal Classification with Image Captioning Using a Synthetic Data Approach

Feb 26, 2025Abstract:The effectiveness of zero-shot classification in large vision-language models (VLMs), such as Contrastive Language-Image Pre-training (CLIP), depends on access to extensive, well-aligned text-image datasets. In this work, we introduce two complementary data sources, one generated by large language models (LLMs) to describe the stages of fungal growth and another comprising a diverse set of synthetic fungi images. These datasets are designed to enhance CLIPs zero-shot classification capabilities for fungi-related tasks. To ensure effective alignment between text and image data, we project them into CLIPs shared representation space, focusing on different fungal growth stages. We generate text using LLaMA3.2 to bridge modality gaps and synthetically create fungi images. Furthermore, we investigate knowledge transfer by comparing text outputs from different LLM techniques to refine classification across growth stages.

Application of Soft Actor-Critic Algorithms in Optimizing Wastewater Treatment with Time Delays Integration

Nov 27, 2024

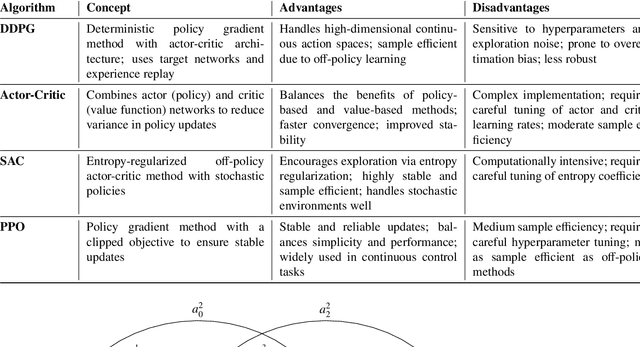

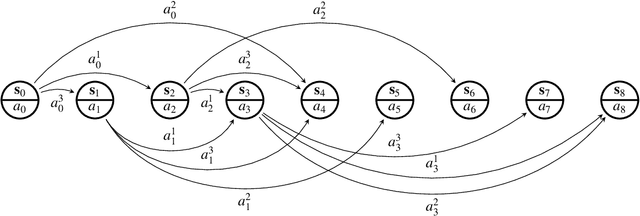

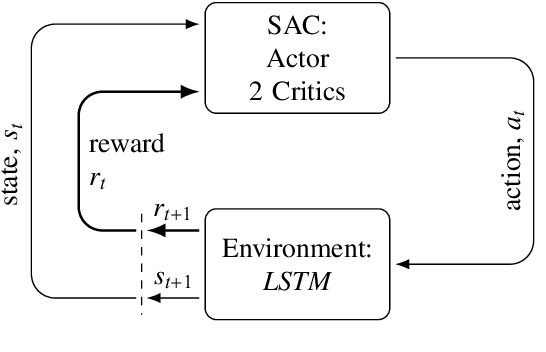

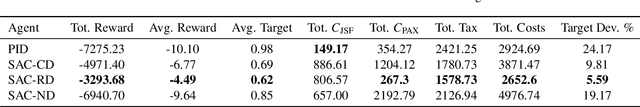

Abstract:Wastewater treatment plants face unique challenges for process control due to their complex dynamics, slow time constants, and stochastic delays in observations and actions. These characteristics make conventional control methods, such as Proportional-Integral-Derivative controllers, suboptimal for achieving efficient phosphorus removal, a critical component of wastewater treatment to ensure environmental sustainability. This study addresses these challenges using a novel deep reinforcement learning approach based on the Soft Actor-Critic algorithm, integrated with a custom simulator designed to model the delayed feedback inherent in wastewater treatment plants. The simulator incorporates Long Short-Term Memory networks for accurate multi-step state predictions, enabling realistic training scenarios. To account for the stochastic nature of delays, agents were trained under three delay scenarios: no delay, constant delay, and random delay. The results demonstrate that incorporating random delays into the reinforcement learning framework significantly improves phosphorus removal efficiency while reducing operational costs. Specifically, the delay-aware agent achieved 36% reduction in phosphorus emissions, 55% higher reward, 77% lower target deviation from the regulatory limit, and 9% lower total costs than traditional control methods in the simulated environment. These findings underscore the potential of reinforcement learning to overcome the limitations of conventional control strategies in wastewater treatment, providing an adaptive and cost-effective solution for phosphorus removal.

Wastewater Treatment Plant Data for Nutrient Removal System

Jul 07, 2024Abstract:This paper introduces the Agtrup (BlueKolding) dataset, collected from Denmark's Agtrup wastewater treatment plant, specifically designed to enhance phosphorus removal via chemical and biological methods. This rich dataset is assembled through a high-frequency Supervisory Control and Data Acquisition (SCADA) system data collection process, which captures a wide range of variables related to the operational dynamics of nutrient removal. It comprises time-series data featuring measurements sampled to a frequency of two minutes across various control, process, and environmental variables. The comprehensive dataset aims to foster significant advancements in wastewater management by supporting the development of sophisticated predictive models and optimizing operational strategies. By providing detailed insights into the interactions and efficiencies of chemical and biological phosphorus removal processes, the dataset serves as a vital resource for environmental researchers and engineers focused on improving the sustainability and effectiveness of wastewater treatment operations. The ultimate goal of this dataset is to facilitate the creation of digital twins and the application of machine learning techniques, such as deep reinforcement learning, to predict and enhance system performance under varying operational conditions.

Improved Long Short-Term Memory-based Wastewater Treatment Simulators for Deep Reinforcement Learning

Mar 22, 2024Abstract:Even though Deep Reinforcement Learning (DRL) showed outstanding results in the fields of Robotics and Games, it is still challenging to implement it in the optimization of industrial processes like wastewater treatment. One of the challenges is the lack of a simulation environment that will represent the actual plant as accurately as possible to train DRL policies. Stochasticity and non-linearity of wastewater treatment data lead to unstable and incorrect predictions of models over long time horizons. One possible reason for the models' incorrect simulation behavior can be related to the issue of compounding error, which is the accumulation of errors throughout the simulation. The compounding error occurs because the model utilizes its predictions as inputs at each time step. The error between the actual data and the prediction accumulates as the simulation continues. We implemented two methods to improve the trained models for wastewater treatment data, which resulted in more accurate simulators: 1- Using the model's prediction data as input in the training step as a tool of correction, and 2- Change in the loss function to consider the long-term predicted shape (dynamics). The experimental results showed that implementing these methods can improve the behavior of simulators in terms of Dynamic Time Warping throughout a year up to 98% compared to the base model. These improvements demonstrate significant promise in creating simulators for biological processes that do not need pre-existing knowledge of the process but instead depend exclusively on time series data obtained from the system.

Advancements in Point Cloud-Based 3D Defect Detection and Classification for Industrial Systems: A Comprehensive Survey

Feb 20, 2024

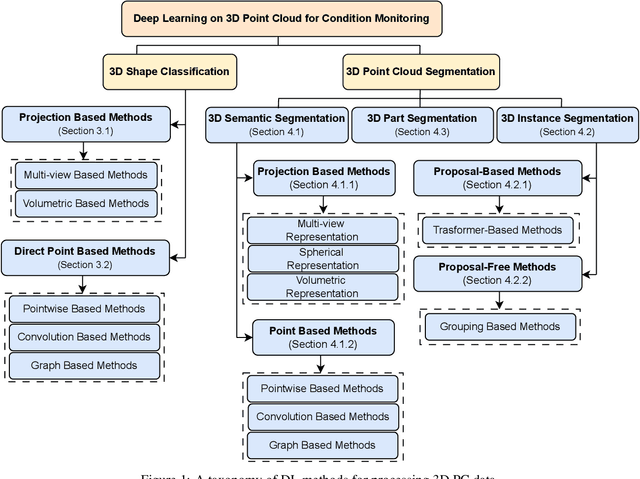

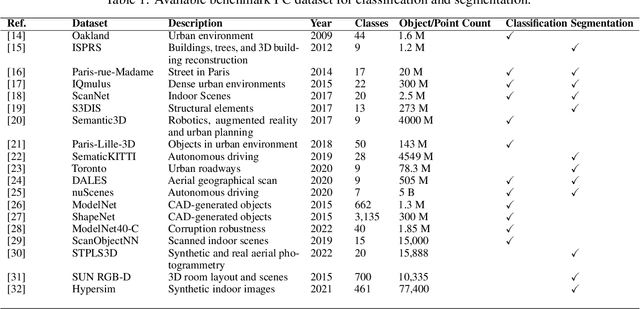

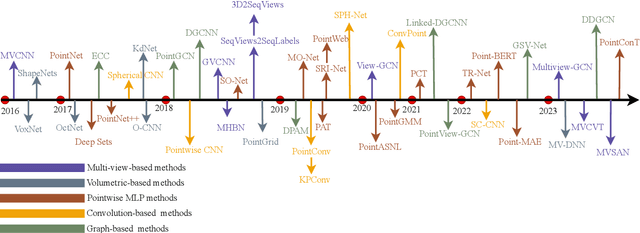

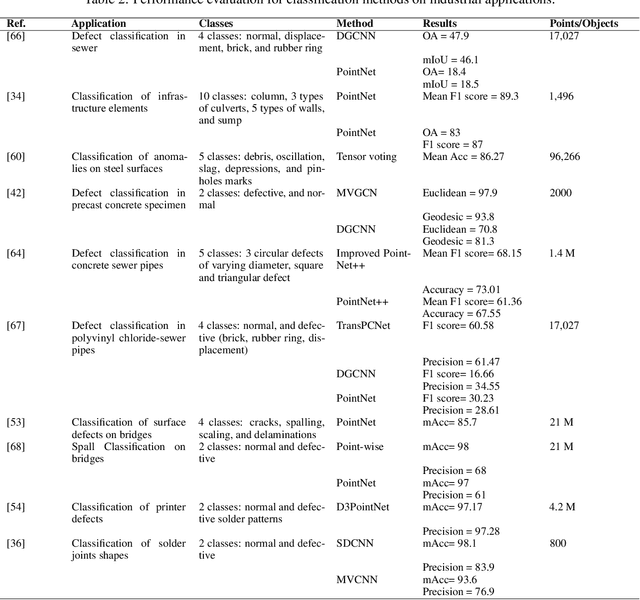

Abstract:In recent years, 3D point clouds (PCs) have gained significant attention due to their diverse applications across various fields such as computer vision (CV), condition monitoring, virtual reality, robotics, autonomous driving etc. Deep learning (DL) has proven effective in leveraging 3D PCs to address various challenges previously encountered in 2D vision. However, the application of deep neural networks (DNN) to process 3D PCs presents its own set of challenges. To address these challenges, numerous methods have been proposed. This paper provides an in-depth review of recent advancements in DL-based condition monitoring (CM) using 3D PCs, with a specific focus on defect shape classification and segmentation within industrial applications for operational and maintenance purposes. Recognizing the crucial role of these aspects in industrial maintenance, the paper provides insightful observations that offer perspectives on the strengths and limitations of the reviewed DL-based PC processing methods. This synthesis of knowledge aims to contribute to the understanding and enhancement of CM processes, particularly within the framework of remaining useful life (RUL), in industrial systems.

Deep Learning Based Simulators for the Phosphorus Removal Process Control in Wastewater Treatment via Deep Reinforcement Learning Algorithms

Jan 23, 2024Abstract:Phosphorus removal is vital in wastewater treatment to reduce reliance on limited resources. Deep reinforcement learning (DRL) is a machine learning technique that can optimize complex and nonlinear systems, including the processes in wastewater treatment plants, by learning control policies through trial and error. However, applying DRL to chemical and biological processes is challenging due to the need for accurate simulators. This study trained six models to identify the phosphorus removal process and used them to create a simulator for the DRL environment. Although the models achieved high accuracy (>97%), uncertainty and incorrect prediction behavior limited their performance as simulators over longer horizons. Compounding errors in the models' predictions were identified as one of the causes of this problem. This approach for improving process control involves creating simulation environments for DRL algorithms, using data from supervisory control and data acquisition (SCADA) systems with a sufficient historical horizon without complex system modeling or parameter estimation.

Design, Modelling and Control of an Amphibious Quad-Rotor for Pipeline Inspection

Oct 02, 2023Abstract:Regular inspections are crucial to maintaining waste-water pipelines in good condition. The challenge is that inside a pipeline the space is narrow and may have a complex structure. The conventional methods that use pipe robots with heavy cables are expensive, time-consuming, and difficult to operate. In this work, we develop an amphibious system that combines a quad-copter with a surface vehicle, creating a hybrid unmanned aerial floating vehicle (HUAFV). Nonlinear dynamics of the HUAFV are modeled based on the dynamic models of both operating modes. The model is validated through experiments and simulations. A PI controller designed and tuned on the developed model is implemented onto a prototype platform. Our experiments demonstrate the effectiveness of the new HUAFV's modeling and design.

Imagery Dataset for Condition Monitoring of Synthetic Fibre Ropes

Sep 29, 2023Abstract:Automatic visual inspection of synthetic fibre ropes (SFRs) is a challenging task in the field of offshore, wind turbine industries, etc. The presence of any defect in SFRs can compromise their structural integrity and pose significant safety risks. Due to the large size and weight of these ropes, it is often impractical to detach and inspect them frequently. Therefore, there is a critical need to develop efficient defect detection methods to assess their remaining useful life (RUL). To address this challenge, a comprehensive dataset has been generated, comprising a total of 6,942 raw images representing both normal and defective SFRs. The dataset encompasses a wide array of defect scenarios which may occur throughout their operational lifespan, including but not limited to placking defects, cut strands, chafings, compressions, core outs and normal. This dataset serves as a resource to support computer vision applications, including object detection, classification, and segmentation, aimed at detecting and analyzing defects in SFRs. The availability of this dataset will facilitate the development and evaluation of robust defect detection algorithms. The aim of generating this dataset is to assist in the development of automated defect detection systems that outperform traditional visual inspection methods, thereby paving the way for safer and more efficient utilization of SFRs across a wide range of applications.

Defect Detection in Synthetic Fibre Ropes using Detectron2 Framework

Sep 04, 2023Abstract:Fibre ropes with the latest technology have emerged as an appealing alternative to steel ropes for offshore industries due to their lightweight and high tensile strength. At the same time, frequent inspection of these ropes is essential to ensure the proper functioning and safety of the entire system. The development of deep learning (DL) models in condition monitoring (CM) applications offers a simpler and more effective approach for defect detection in synthetic fibre ropes (SFRs). The present paper investigates the performance of Detectron2, a state-of-the-art library for defect detection and instance segmentation. Detectron2 with Mask R-CNN architecture is used for segmenting defects in SFRs. Mask R-CNN with various backbone configurations has been trained and tested on an experimentally obtained dataset comprising 1,803 high-dimensional images containing seven damage classes (loop high, loop medium, loop low, compression, core out, abrasion, and normal respectively) for SFRs. By leveraging the capabilities of Detectron2, this study aims to develop an automated and efficient method for detecting defects in SFRs, enhancing the inspection process, and ensuring the safety of the fibre ropes.

Add to Chrome

Add to Chrome Add to Firefox

Add to Firefox Add to Edge

Add to Edge