Anju Rani

FungalZSL: Zero-Shot Fungal Classification with Image Captioning Using a Synthetic Data Approach

Feb 26, 2025Abstract:The effectiveness of zero-shot classification in large vision-language models (VLMs), such as Contrastive Language-Image Pre-training (CLIP), depends on access to extensive, well-aligned text-image datasets. In this work, we introduce two complementary data sources, one generated by large language models (LLMs) to describe the stages of fungal growth and another comprising a diverse set of synthetic fungi images. These datasets are designed to enhance CLIPs zero-shot classification capabilities for fungi-related tasks. To ensure effective alignment between text and image data, we project them into CLIPs shared representation space, focusing on different fungal growth stages. We generate text using LLaMA3.2 to bridge modality gaps and synthetically create fungi images. Furthermore, we investigate knowledge transfer by comparing text outputs from different LLM techniques to refine classification across growth stages.

Wastewater Treatment Plant Data for Nutrient Removal System

Jul 07, 2024Abstract:This paper introduces the Agtrup (BlueKolding) dataset, collected from Denmark's Agtrup wastewater treatment plant, specifically designed to enhance phosphorus removal via chemical and biological methods. This rich dataset is assembled through a high-frequency Supervisory Control and Data Acquisition (SCADA) system data collection process, which captures a wide range of variables related to the operational dynamics of nutrient removal. It comprises time-series data featuring measurements sampled to a frequency of two minutes across various control, process, and environmental variables. The comprehensive dataset aims to foster significant advancements in wastewater management by supporting the development of sophisticated predictive models and optimizing operational strategies. By providing detailed insights into the interactions and efficiencies of chemical and biological phosphorus removal processes, the dataset serves as a vital resource for environmental researchers and engineers focused on improving the sustainability and effectiveness of wastewater treatment operations. The ultimate goal of this dataset is to facilitate the creation of digital twins and the application of machine learning techniques, such as deep reinforcement learning, to predict and enhance system performance under varying operational conditions.

Advancements in Point Cloud-Based 3D Defect Detection and Classification for Industrial Systems: A Comprehensive Survey

Feb 20, 2024

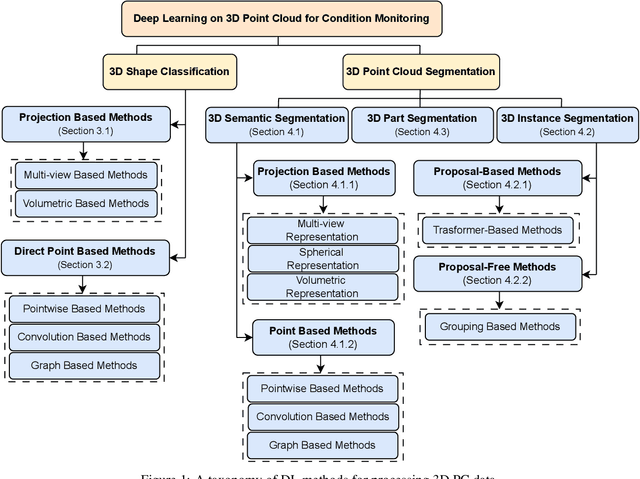

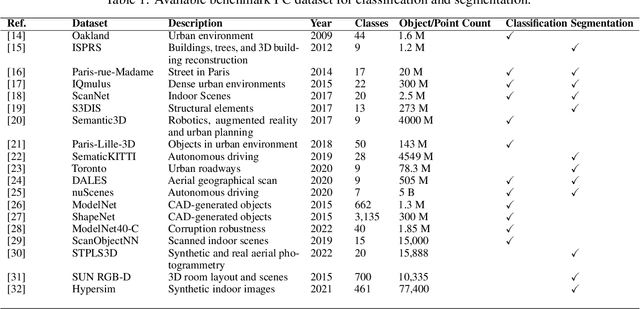

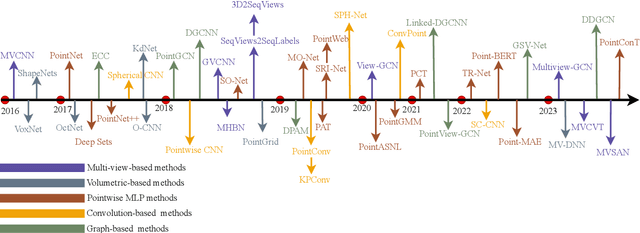

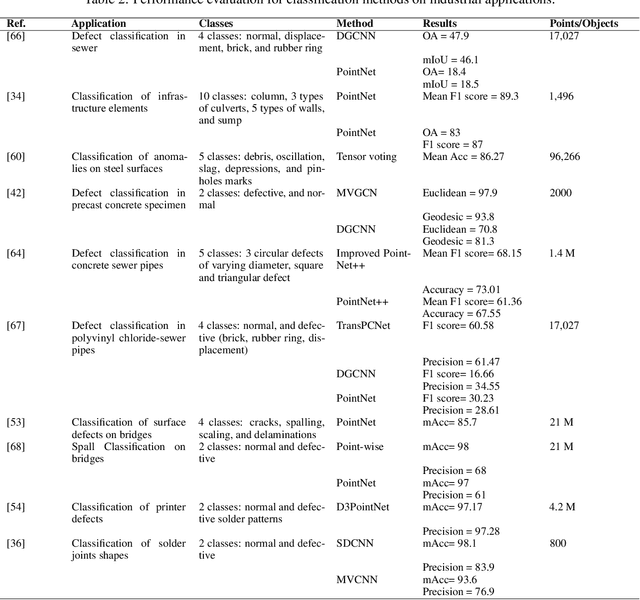

Abstract:In recent years, 3D point clouds (PCs) have gained significant attention due to their diverse applications across various fields such as computer vision (CV), condition monitoring, virtual reality, robotics, autonomous driving etc. Deep learning (DL) has proven effective in leveraging 3D PCs to address various challenges previously encountered in 2D vision. However, the application of deep neural networks (DNN) to process 3D PCs presents its own set of challenges. To address these challenges, numerous methods have been proposed. This paper provides an in-depth review of recent advancements in DL-based condition monitoring (CM) using 3D PCs, with a specific focus on defect shape classification and segmentation within industrial applications for operational and maintenance purposes. Recognizing the crucial role of these aspects in industrial maintenance, the paper provides insightful observations that offer perspectives on the strengths and limitations of the reviewed DL-based PC processing methods. This synthesis of knowledge aims to contribute to the understanding and enhancement of CM processes, particularly within the framework of remaining useful life (RUL), in industrial systems.

Imagery Dataset for Condition Monitoring of Synthetic Fibre Ropes

Sep 29, 2023Abstract:Automatic visual inspection of synthetic fibre ropes (SFRs) is a challenging task in the field of offshore, wind turbine industries, etc. The presence of any defect in SFRs can compromise their structural integrity and pose significant safety risks. Due to the large size and weight of these ropes, it is often impractical to detach and inspect them frequently. Therefore, there is a critical need to develop efficient defect detection methods to assess their remaining useful life (RUL). To address this challenge, a comprehensive dataset has been generated, comprising a total of 6,942 raw images representing both normal and defective SFRs. The dataset encompasses a wide array of defect scenarios which may occur throughout their operational lifespan, including but not limited to placking defects, cut strands, chafings, compressions, core outs and normal. This dataset serves as a resource to support computer vision applications, including object detection, classification, and segmentation, aimed at detecting and analyzing defects in SFRs. The availability of this dataset will facilitate the development and evaluation of robust defect detection algorithms. The aim of generating this dataset is to assist in the development of automated defect detection systems that outperform traditional visual inspection methods, thereby paving the way for safer and more efficient utilization of SFRs across a wide range of applications.

Defect Detection in Synthetic Fibre Ropes using Detectron2 Framework

Sep 04, 2023Abstract:Fibre ropes with the latest technology have emerged as an appealing alternative to steel ropes for offshore industries due to their lightweight and high tensile strength. At the same time, frequent inspection of these ropes is essential to ensure the proper functioning and safety of the entire system. The development of deep learning (DL) models in condition monitoring (CM) applications offers a simpler and more effective approach for defect detection in synthetic fibre ropes (SFRs). The present paper investigates the performance of Detectron2, a state-of-the-art library for defect detection and instance segmentation. Detectron2 with Mask R-CNN architecture is used for segmenting defects in SFRs. Mask R-CNN with various backbone configurations has been trained and tested on an experimentally obtained dataset comprising 1,803 high-dimensional images containing seven damage classes (loop high, loop medium, loop low, compression, core out, abrasion, and normal respectively) for SFRs. By leveraging the capabilities of Detectron2, this study aims to develop an automated and efficient method for detecting defects in SFRs, enhancing the inspection process, and ensuring the safety of the fibre ropes.

Add to Chrome

Add to Chrome Add to Firefox

Add to Firefox Add to Edge

Add to Edge