Pasquale Chiacchio

Simplifying ROS2 controllers with a modular architecture for robot-agnostic reference generation

Jan 13, 2026Abstract:This paper introduces a novel modular architecture for ROS2 that decouples the logic required to acquire, validate, and interpolate references from the control laws that track them. The design includes a dedicated component, named Reference Generator, that receives references, in the form of either single points or trajectories, from external nodes (e.g., planners), and writes single-point references at the controller's sampling period via the existing ros2_control chaining mechanism to downstream controllers. This separation removes duplicated reference-handling code from controllers and improves reusability across robot platforms. We implement two reference generators: one for handling joint-space references and one for Cartesian references, along with a set of new controllers (PD with gravity compensation, Cartesian pose, and admittance controllers) and validate the approach on simulated and real Universal Robots and Franka Emika manipulators. Results show that (i) references are tracked reliably in all tested scenarios, (ii) reference generators reduce duplicated reference-handling code across chained controllers to favor the construction and reuse of complex controller pipelines, and (iii) controller implementations remain focused only on control laws.

Improving dependability in robotized bolting operations

Nov 13, 2025Abstract:Bolting operations are critical in industrial assembly and in the maintenance of scientific facilities, requiring high precision and robustness to faults. Although robotic solutions have the potential to improve operational safety and effectiveness, current systems still lack reliable autonomy and fault management capabilities. To address this gap, we propose a control framework for dependable robotized bolting tasks and instantiate it on a specific robotic system. The system features a control architecture ensuring accurate driving torque control and active compliance throughout the entire operation, enabling safe interaction even under fault conditions. By designing a multimodal human-robot interface (HRI) providing real-time visualization of relevant system information and supporting seamless transitions between automatic and manual control, we improve operator situation awareness and fault detection capabilities. A high-level supervisor (SV) coordinates the execution and manages transitions between control modes, ensuring consistency with the supervisory control (SVC) paradigm, while preserving the human operator's authority. The system is validated in a representative bolting operation involving pipe flange joining, under several fault conditions. The results demonstrate improved fault detection capabilities, enhanced operator situational awareness, and accurate and compliant execution of the bolting operation. However, they also reveal the limitations of relying on a single camera to achieve full situational awareness.

Augmenting Neural Networks-based Model Approximators in Robotic Force-tracking Tasks

Sep 10, 2025Abstract:As robotics gains popularity, interaction control becomes crucial for ensuring force tracking in manipulator-based tasks. Typically, traditional interaction controllers either require extensive tuning, or demand expert knowledge of the environment, which is often impractical in real-world applications. This work proposes a novel control strategy leveraging Neural Networks (NNs) to enhance the force-tracking behavior of a Direct Force Controller (DFC). Unlike similar previous approaches, it accounts for the manipulator's tangential velocity, a critical factor in force exertion, especially during fast motions. The method employs an ensemble of feedforward NNs to predict contact forces, then exploits the prediction to solve an optimization problem and generate an optimal residual action, which is added to the DFC output and applied to an impedance controller. The proposed Velocity-augmented Artificial intelligence Interaction Controller for Ambiguous Models (VAICAM) is validated in the Gazebo simulator on a Franka Emika Panda robot. Against a vast set of trajectories, VAICAM achieves superior performance compared to two baseline controllers.

A ROS2-based software library for inverse dynamics computation

Apr 08, 2025

Abstract:Inverse dynamics computation is a critical component in robot control, planning and simulation, enabling the calculation of joint torques required to achieve a desired motion. This paper presents a ROS2-based software library designed to solve the inverse dynamics problem for robotic systems. The library is built around an abstract class with three concrete implementations: one for simulated robots and two for real UR10 and Franka robots. This contribution aims to provide a flexible, extensible, robot-agnostic solution to inverse dynamics, suitable for both simulation and real-world scenarios involving planning and control applications. The related software is available at https://github.com/ros2-gbp/ros2-gbp-github-org/issues/732.

The Dynamic Model of the UR10 Robot and its ROS2 Integration

Feb 17, 2025

Abstract:This paper presents the full dynamic model of the UR10 industrial robot. A triple-stage identification approach is adopted to estimate the manipulator's dynamic coefficients. First, linear parameters are computed using a standard linear regression algorithm. Subsequently, nonlinear friction parameters are estimated according to a sigmoidal model. Lastly, motor drive gains are devised to map estimated joint currents to torques. The overall identified model can be used for both control and planning purposes, as the accompanied ROS2 software can be easily reconfigured to account for a generic payload. The estimated robot model is experimentally validated against a set of exciting trajectories and compared to the state-of-the-art model for the same manipulator, achieving higher current prediction accuracy (up to a factor of 4.43) and more precise motor gains. The related software is available at https://codeocean.com/capsule/8515919/tree/v2.

On the role of Artificial Intelligence methods in modern force-controlled manufacturing robotic tasks

Sep 25, 2024

Abstract:This position paper explores the integration of Artificial Intelligence (AI) into force-controlled robotic tasks within the scope of advanced manufacturing, a cornerstone of Industry 4.0. AI's role in enhancing robotic manipulators - key drivers in the Fourth Industrial Revolution - is rapidly leading to significant innovations in smart manufacturing. The objective of this article is to frame these innovations in practical force-controlled applications - e.g. deburring, polishing, and assembly tasks like peg-in-hole (PiH) - highlighting their necessity for maintaining high-quality production standards. By reporting on recent AI-based methodologies, this article contrasts them and identifies current challenges to be addressed in future research. The analysis concludes with a perspective on future research directions, emphasizing the need for common performance metrics to validate AI techniques, integration of various enhancements for performance optimization, and the importance of validating them in relevant scenarios. These future directions aim to provide consistency with already adopted approaches, so as to be compatible with manufacturing standards, increasing the relevance of AI-driven methods in both academic and industrial contexts.

Human-Robot Interface for Teleoperated Robotized Planetary Sample Collection and Assembly

Jun 13, 2024

Abstract:As human space exploration evolves toward longer voyages farther from our home planet, in-situ resource utilization (ISRU) becomes increasingly important. Haptic teleoperations are one of the technologies by which such activities can be carried out remotely by humans, whose expertise is still necessary for complex activities. In order to perform precision tasks with effectiveness, the operator must experience ease of use and accuracy. The same features are demanded to reduce the complexity of the training procedures and the associated learning time for operators without a specific background in robotic teleoperations. Haptic teleoperation systems, that allow for a natural feeling of forces, need to cope with the trade-off between accurate movements and workspace extension. Clearly, both of them are required for typical ISRU tasks. In this work, we develop a new concept of operations and suitable human-robot interfaces to achieve sample collection and assembly with ease of use and accuracy. In the proposed operational concept, the teleoperation space is extended by executing automated trajectories, offline planned at the control station. In three different experimental scenarios, we validate the end-to-end system involving the control station and the robotic asset, by assessing the contribution of haptics to mission success, the system robustness to consistent delays, and the ease of training new operators.

Optimal Whole Body Trajectory Planning for Mobile Manipulators in Planetary Exploration and Construction

May 23, 2024Abstract:Space robotics poses unique challenges arising from the limitation of energy and computational resources, and the complexity of the environment and employed platforms. At the control center, offline motion planning is fundamental in the computation of optimized trajectories accounting for the system's constraints. Smooth movements, collision and forbidden areas avoidance, target visibility and energy consumption are all important factors to consider to be able to generate feasible and optimal plans. When mobile manipulators (terrestrial, aerial) are employed, the base and the arm movements are often separately planned, ultimately resulting in sub-optimal solutions. We propose an Optimal Whole Body Planner (OptiWB) based on Discrete Dynamic Programming (DDP) and optimal interpolation. Kinematic redundancy is exploited for collision and forbidden areas avoidance, and to improve target illumination and visibility from onboard cameras. The planner, implemented in ROS (Robot Operating System), interfaces 3DROCS, a mission planner used in several programs of the European Space Agency (ESA) to support planetary exploration surface missions and part of the ExoMars Rover's planning software. The proposed approach is exercised on a simplified version of the Analog-1 Interact rover by ESA, a 7-DOFs robotic arm mounted on a four wheels non-holonomic platform.

A Dynamic Programming Framework for Optimal Planning of Redundant Robots Along Prescribed Paths With Kineto-Dynamic Constraints

Jul 12, 2022

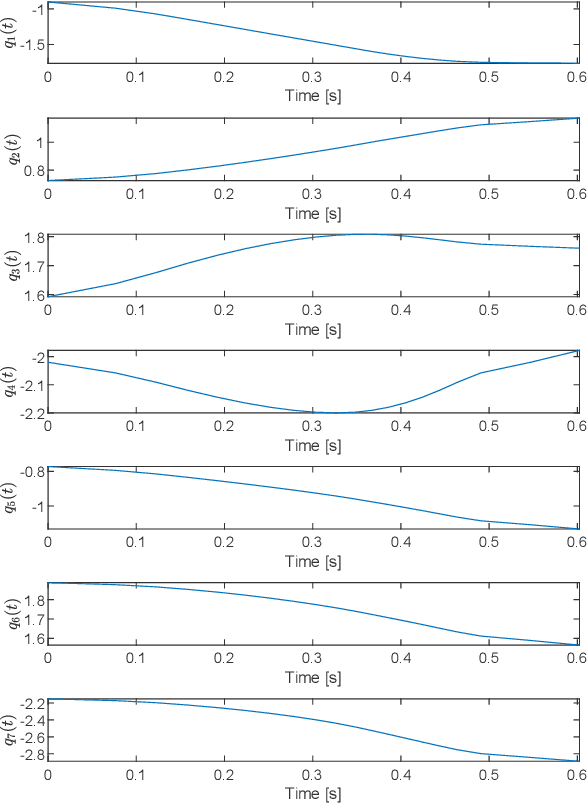

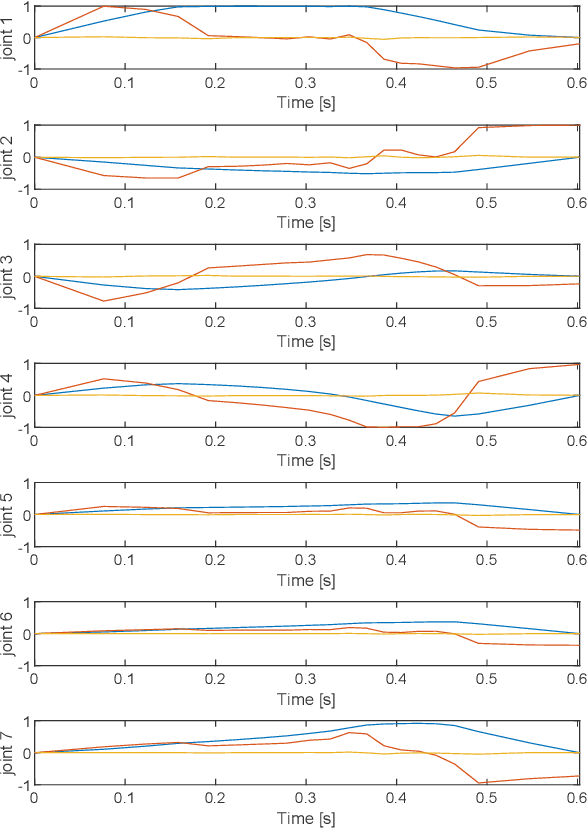

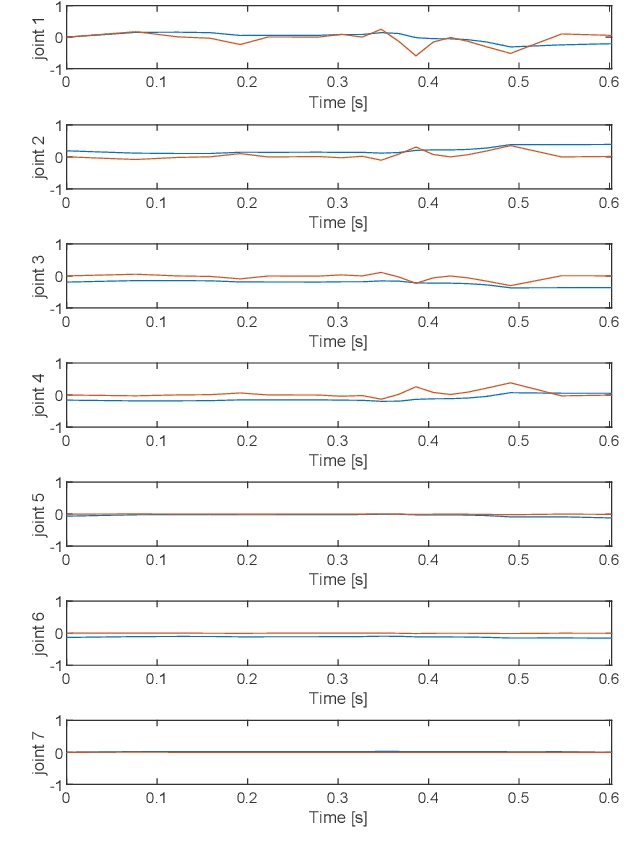

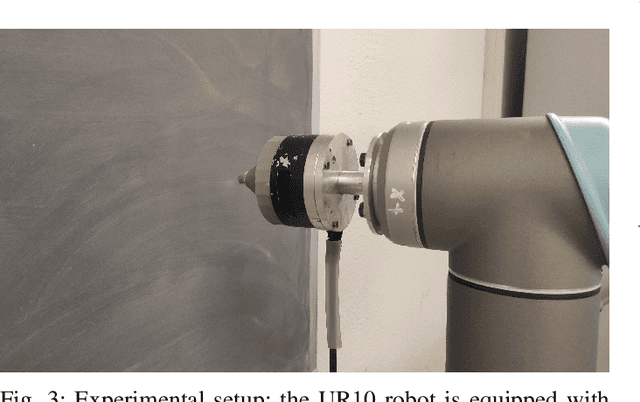

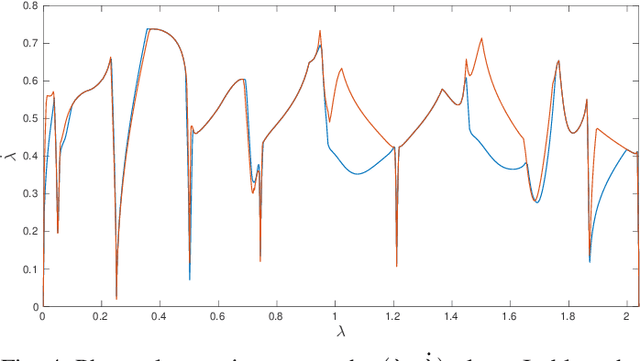

Abstract:Off-line optimal planning of trajectories for redundant robots along prescribed task space paths is usually broken down into two consecutive processes: first, the task space path is inverted to obtain a joint-space path, then, the latter is parametrized with a time law. If the two processes are separated, they cannot optimize the same objective function, ultimately providing sub-optimal results. In this paper, a unified approach is presented where dynamic programming is the underlying optimization technique. Its flexibility allows accommodating arbitrary constraints and objective functions, thus providing a generic framework for optimal planning of real systems. To demonstrate its applicability to a real world scenario, the framework is instantiated for time-optimality. Compared to numerical solvers, the proposed methodology provides visibility of the underlying resolution process, allowing for further analyses beyond the computation of the optimal trajectory. The effectiveness of the framework is demonstrated on a real 7-degrees-of-freedom serial chain. The issues associated with the execution of optimal trajectories on a real controller are also discussed and addressed. The experiments show that the proposed framework is able to effectively exploit kinematic redundancy to optimize the performance index defined at planning level and generate feasible trajectories that can be executed on real hardware with satisfactory results.

Time-Optimal Trajectory Planning with Interaction with the Environment

Jul 12, 2022

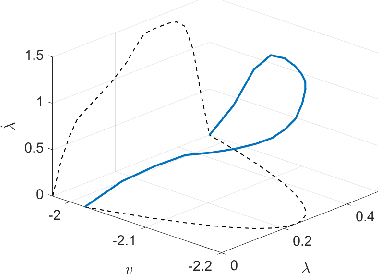

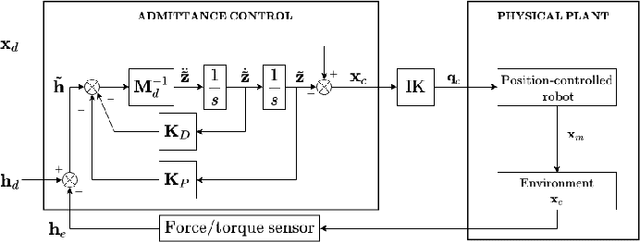

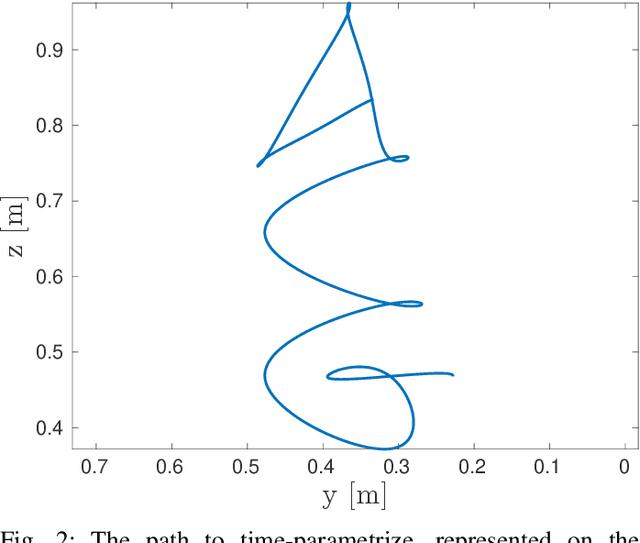

Abstract:Optimal motion planning along prescribed paths can be solved with several techniques, but most of them do not take into account the wrenches exerted by the end-effector when in contact with the environment. When a dynamic model of the environment is not available, no consolidated methodology exists to consider the effect of the interaction. Regardless of the specific performance index to optimize, this article proposes a strategy to include external wrenches in the optimal planning algorithm, considering the task specifications. This procedure is instantiated for minimum-time trajectories and validated on a real robot performing an interaction task under admittance control. The results prove that the inclusion of end-effector wrenches affect the planned trajectory, in fact modifying the manipulator's dynamic capability.

Add to Chrome

Add to Chrome Add to Firefox

Add to Firefox Add to Edge

Add to Edge