Nysret Musliu

Intermediate Languages Matter: Formal Languages and LLMs affect Neurosymbolic Reasoning

Sep 04, 2025Abstract:Large language models (LLMs) achieve astonishing results on a wide range of tasks. However, their formal reasoning ability still lags behind. A promising approach is Neurosymbolic LLM reasoning. It works by using LLMs as translators from natural to formal languages and symbolic solvers for deriving correct results. Still, the contributing factors to the success of Neurosymbolic LLM reasoning remain unclear. This paper demonstrates that one previously overlooked factor is the choice of the formal language. We introduce the intermediate language challenge: selecting a suitable formal language for neurosymbolic reasoning. By comparing four formal languages across three datasets and seven LLMs, we show that the choice of formal language affects both syntactic and semantic reasoning capabilities. We also discuss the varying effects across different LLMs.

ASP-FZN: A Translation-based Constraint Answer Set Solver

Jul 30, 2025Abstract:We present the solver asp-fzn for Constraint Answer Set Programming (CASP), which extends ASP with linear constraints. Our approach is based on translating CASP programs into the solver-independent FlatZinc language that supports several Constraint Programming and Integer Programming backend solvers. Our solver supports a rich language of linear constraints, including some common global constraints. As for evaluation, we show that asp-fzn is competitive with state-of-the-art ASP solvers on benchmarks taken from past ASP competitions. Furthermore, we evaluate it on several CASP problems from the literature and compare its performance with clingcon, which is a prominent CASP solver that supports most of the asp-fzn language. The performance of asp-fzn is very promising as it is already competitive on plain ASP and even outperforms clingcon on some CASP benchmarks.

Integrating Column Generation and Large Neighborhood Search for Bus Driver Scheduling with Complex Break Constraints

May 05, 2025

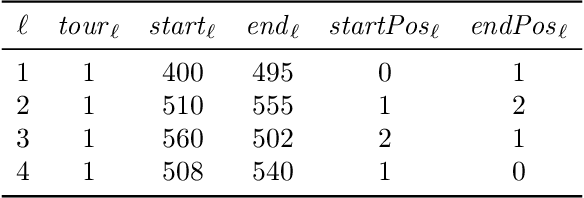

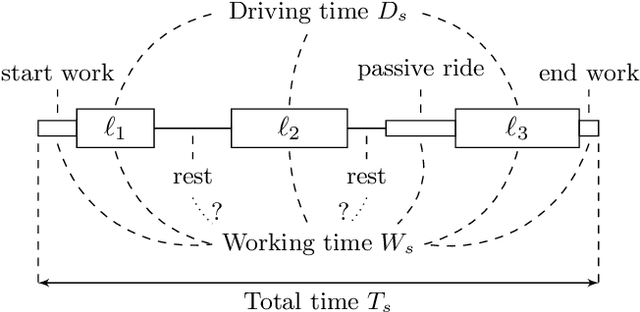

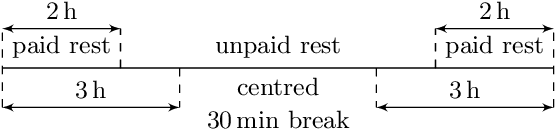

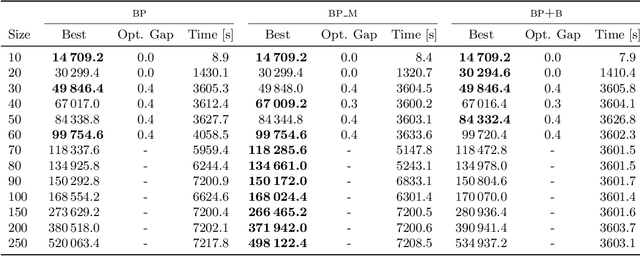

Abstract:The Bus Driver Scheduling Problem (BDSP) is a combinatorial optimization problem with the goal to design shifts to cover prearranged bus tours. The objective takes into account the operational cost as well as the satisfaction of drivers. This problem is heavily constrained due to strict legal rules and collective agreements. The objective of this article is to provide state-of-the-art exact and hybrid solution methods that can provide high-quality solutions for instances of different sizes. This work presents a comprehensive study of both an exact method, Branch and Price (B&P), as well as a Large Neighborhood Search (LNS) framework which uses B&P or Column Generation (CG) for the repair phase to solve the BDSP. It further proposes and evaluates a novel deeper integration of B&P and LNS, storing the generated columns from the LNS subproblems and reusing them for other subproblems, or to find better global solutions. The article presents a detailed analysis of several components of the solution methods and their impact, including general improvements for the B&P subproblem, which is a high-dimensional Resource Constrained Shortest Path Problem (RCSPP), and the components of the LNS. The evaluation shows that our approach provides new state-of-the-art results for instances of all sizes, including exact solutions for small instances, and low gaps to a known lower bound for mid-sized instances. Conclusions: We observe that B&P provides the best results for small instances, while the tight integration of LNS and CG can provide high-quality solutions for larger instances, further improving over LNS which just uses CG as a black box. The proposed methods are general and can also be applied to other rule sets and related optimization problems

Theoretical Lower Bounds for the Oven Scheduling Problem

Oct 02, 2024

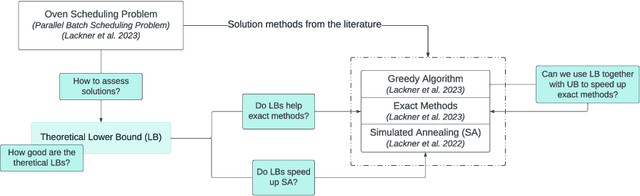

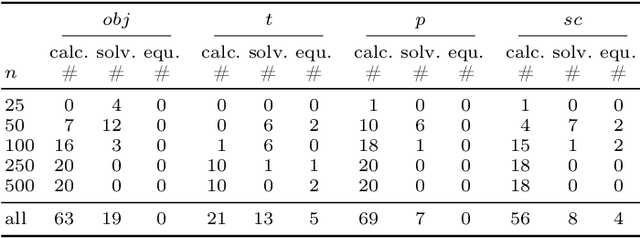

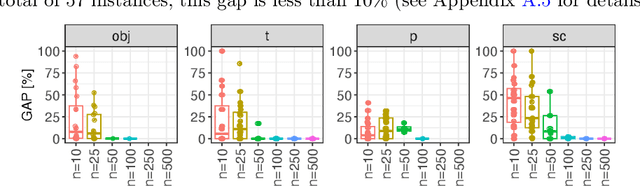

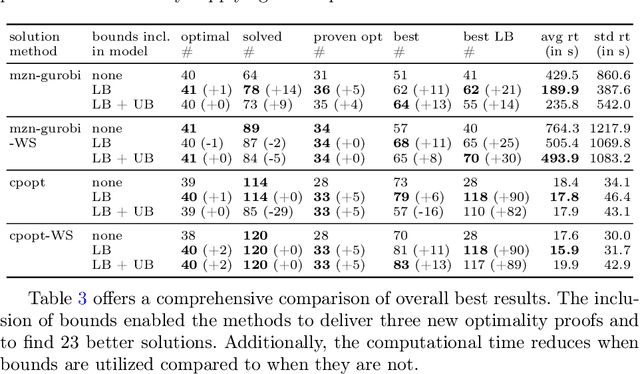

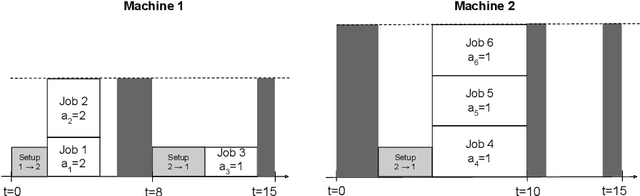

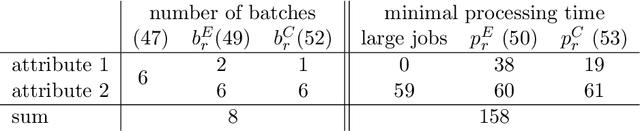

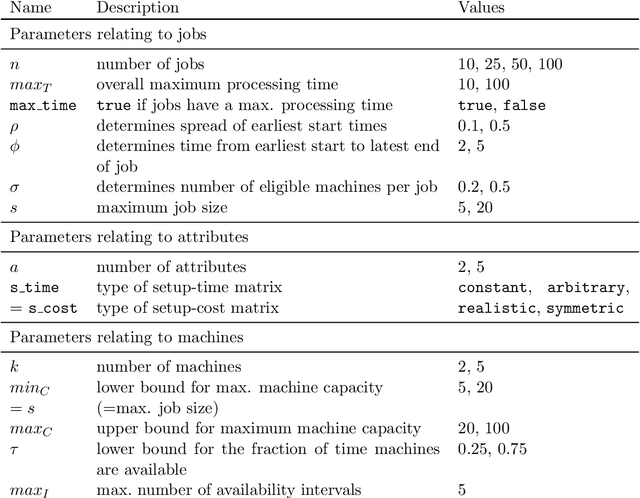

Abstract:The Oven Scheduling Problem (OSP) is an NP-hard real-world parallel batch scheduling problem arising in the semiconductor industry. The objective of the problem is to schedule a set of jobs on ovens while minimizing several factors, namely total oven runtime, job tardiness, and setup costs. At the same time, it must adhere to various constraints such as oven eligibility and availability, job release dates, setup times between batches, and oven capacity limitations. The key to obtaining efficient schedules is to process compatible jobs simultaneously in batches. In this paper, we develop theoretical, problem-specific lower bounds for the OSP that can be computed very quickly. We thoroughly examine these lower bounds, evaluating their quality and exploring their integration into existing solution methods. Specifically, we investigate their contribution to exact methods and a metaheuristic local search approach using simulated annealing. Moreover, these problem-specific lower bounds enable us to assess the solution quality for large instances for which exact methods often fail to provide tight lower bounds.

* arXiv admin note: text overlap with arXiv:2203.12517

Answer-Set Programming for Lexicographical Makespan Optimisation in Parallel Machine Scheduling

Dec 18, 2022

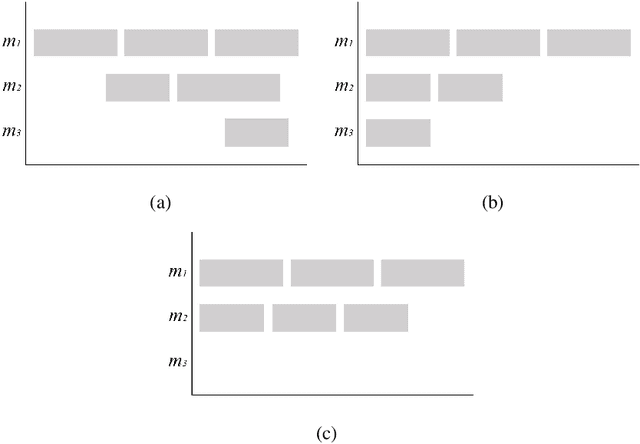

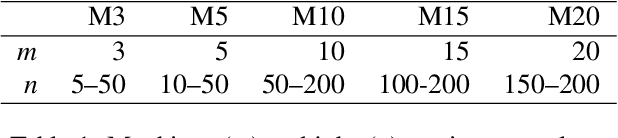

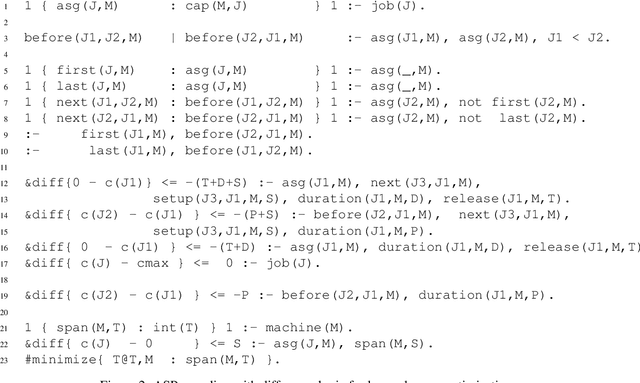

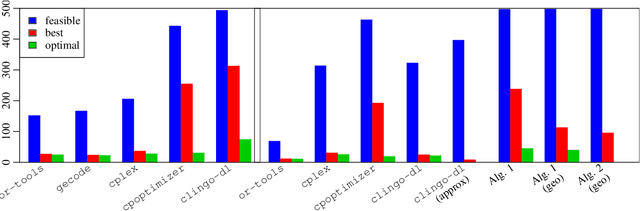

Abstract:We deal with a challenging scheduling problem on parallel machines with sequence-dependent setup times and release dates from a real-world application of semiconductor work-shop production. There, jobs can only be processed by dedicated machines, thus few machines can determine the makespan almost regardless of how jobs are scheduled on the remaining ones. This causes problems when machines fail and jobs need to be rescheduled. Instead of optimising only the makespan, we put the individual machine spans in non-ascending order and lexicographically minimise the resulting tuples. This achieves that all machines complete as early as possible and increases the robustness of the schedule. We study the application of Answer-Set Programming (ASP) to solve this problem. While ASP eases modelling, the combination of timing constraints and the considered objective function challenges current solving technology. The former issue is addressed by using an extension of ASP by difference logic. For the latter, we devise different algorithms that use multi-shot solving. To tackle industrial-sized instances, we study different approximations and heuristics. Our experimental results show that ASP is indeed a promising KRR paradigm for this problem and is competitive with state-of-the-art CP and MIP solvers. Under consideration in Theory and Practice of Logic Programming (TPLP).

Exact methods and lower bounds for the Oven Scheduling Problem

Mar 23, 2022

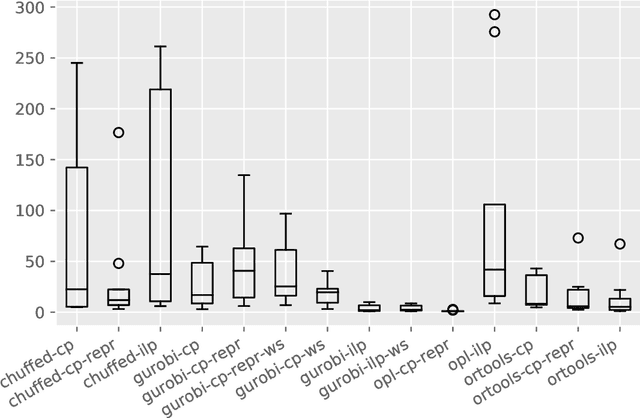

Abstract:The Oven Scheduling Problem (OSP) is a new parallel batch scheduling problem that arises in the area of electronic component manufacturing. Jobs need to be scheduled to one of several ovens and may be processed simultaneously in one batch if they have compatible requirements. The scheduling of jobs must respect several constraints concerning eligibility and availability of ovens, release dates of jobs, setup times between batches as well as oven capacities. Running the ovens is highly energy-intensive and thus the main objective, besides finishing jobs on time, is to minimize the cumulative batch processing time across all ovens. This objective distinguishes the OSP from other batch processing problems which typically minimize objectives related to makespan, tardiness or lateness. We propose to solve this NP-hard scheduling problem via constraint programming (CP) and integer linear programming (ILP) and present corresponding models. For an experimental evaluation, we introduce a multi-parameter random instance generator to provide a diverse set of problem instances. Using state-of-the-art solvers, we evaluate the quality and compare the performance of our CP- and ILP-models. We show that our models can find feasible solutions for instances of realistic size, many of those being provably optimal or nearly optimal solutions. Finally, we derive theoretical lower bounds on the solution cost of feasible solutions to the OSP; these can be computed within a few seconds. We show that these lower bounds are competitive with those derived by state-of-the-art solvers.

Exact and Metaheuristic Approaches for the Production Leveling Problem

Jun 15, 2020

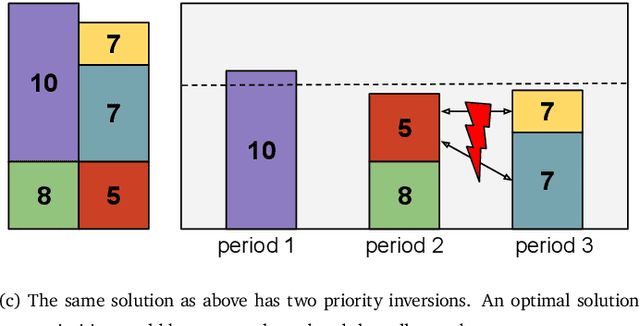

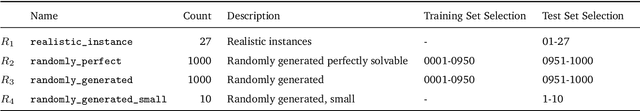

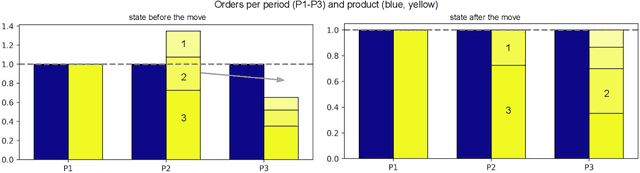

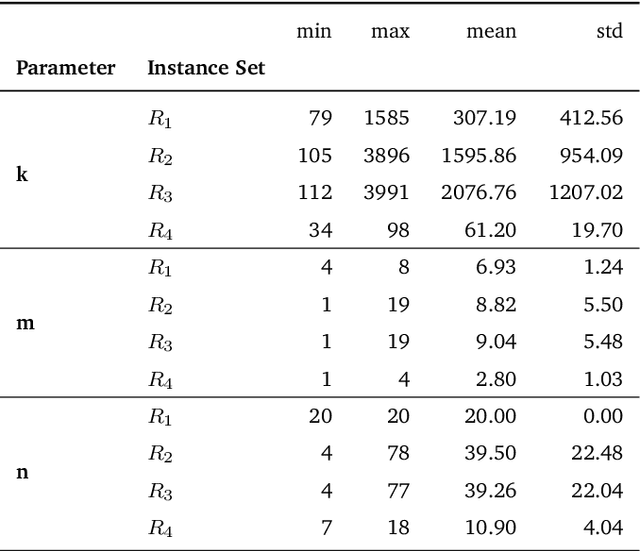

Abstract:In this paper we introduce a new problem in the field of production planning which we call the Production Leveling Problem. The task is to assign orders to production periods such that the load in each period and on each production resource is balanced, capacity limits are not exceeded and the orders' priorities are taken into account. Production Leveling is an important intermediate step between long-term planning and the final scheduling of orders within a production period, as it is responsible for selecting good subsets of orders to be scheduled within each period. A formal model of the problem is proposed and NP-hardness is shown by reduction from Bin Backing. As an exact method for solving moderately sized instances we introduce a MIP formulation. For solving large problem instances, metaheuristic local search is investigated. A greedy heuristic and two neighborhood structures for local search are proposed, in order to apply them using Variable Neighborhood Descent and Simulated Annealing. Regarding exact techniques, the main question of research is, up to which size instances are solvable within a fixed amount of time. For the metaheuristic approaches the aim is to show that they produce near-optimal solutions for smaller instances, but also scale well to very large instances. A set of realistic problem instances from an industrial partner is contributed to the literature, as well as random instance generators. The experimental evaluation conveys that the proposed MIP model works well for instances with up to 250 orders. Out of the investigated metaheuristic approaches, Simulated Annealing achieves the best results. It is shown to produce solutions with less than 3% average optimality gap on small instances and to scale well up to thousands of orders and dozens of periods and products. The presented metaheuristic methods are already being used in the industry.

Investigating Constraint Programming and Hybrid Methods for Real World Industrial Test Laboratory Scheduling

Nov 12, 2019

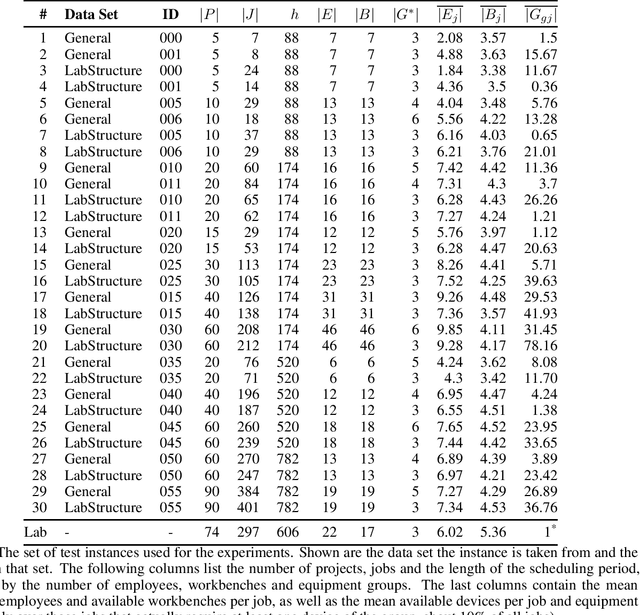

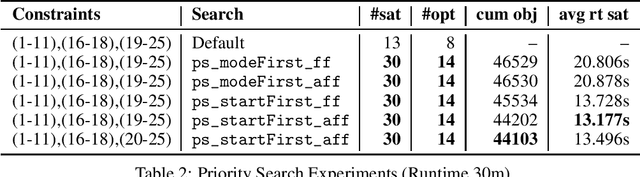

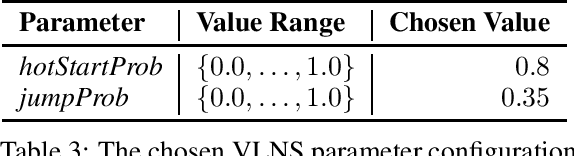

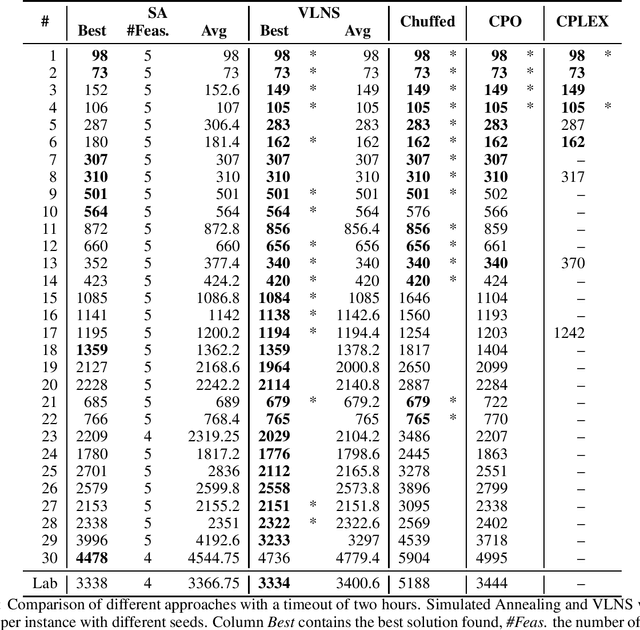

Abstract:In this paper we deal with a complex real world scheduling problem closely related to the well-known Resource-Constrained Project Scheduling Problem (RCPSP). The problem concerns industrial test laboratories in which a large number of tests has to be performed by qualified personnel using specialised equipment, while respecting deadlines and other constraints. We present different constraint programming models and search strategies for this problem. Furthermore, we propose a Very Large Neighborhood Search approach based on our CP methods. Our models are evaluated using CP solvers and a MIP solver both on real-world test laboratory data and on a set of generated instances of different sizes based on the real-world data. Further, we compare the exact approaches with VLNS and a Simulated Annealing heuristic. We could find feasible solutions for all instances and several optimal solutions and we show that using VLNS we can improve upon the results of the other approaches.

Add to Chrome

Add to Chrome Add to Firefox

Add to Firefox Add to Edge

Add to Edge