Nikolay Bykov

Human-Assisted Robotic Detection of Foreign Object Debris Inside Confined Spaces of Marine Vessels Using Probabilistic Mapping

Jul 01, 2022

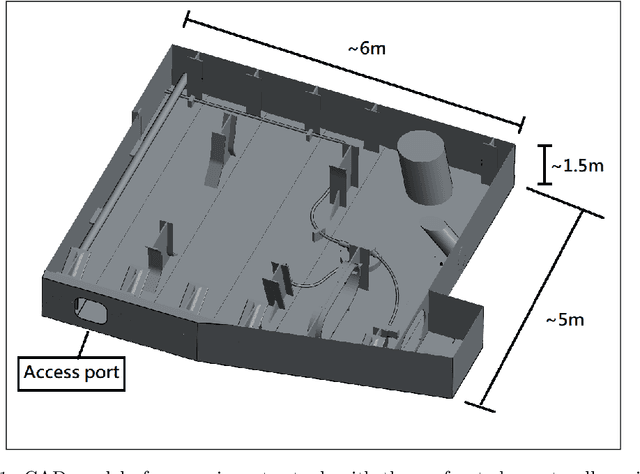

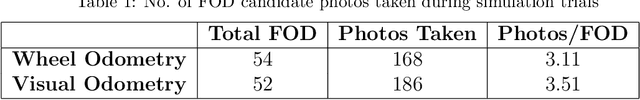

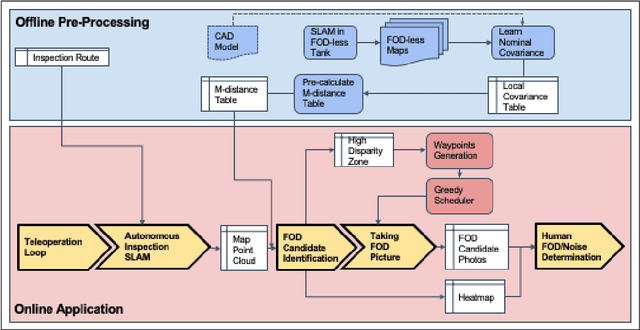

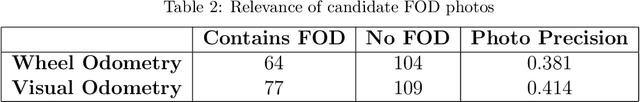

Abstract:Many complex vehicular systems, such as large marine vessels, contain confined spaces like water tanks, which are critical for the safe functioning of the vehicles. It is particularly hazardous for humans to inspect such spaces due to limited accessibility, poor visibility, and unstructured configuration. While robots provide a viable alternative, they encounter the same set of challenges in realizing robust autonomy. In this work, we specifically address the problem of detecting foreign object debris (FODs) left inside the confined spaces using a visual mapping-based system that relies on Mahalanobis distance-driven comparisons between the nominal and online maps for local outlier identification. Simulation trials show extremely high recall but low precision for the outlier identification method. The assistance of remote humans is, therefore, taken to deal with the precision problem by going over the close-up robot camera images of the outlier regions. An online survey is conducted to show the usefulness of this assistance process. Physical experiments are also reported on a GPU-enabled mobile robot platform inside a scaled-down, prototype tank to demonstrate the feasibility of the FOD detection system.

An Efficient Scheduling Algorithm for Multi-Robot Task Allocation in Assembling Aircraft Structures

Feb 24, 2019

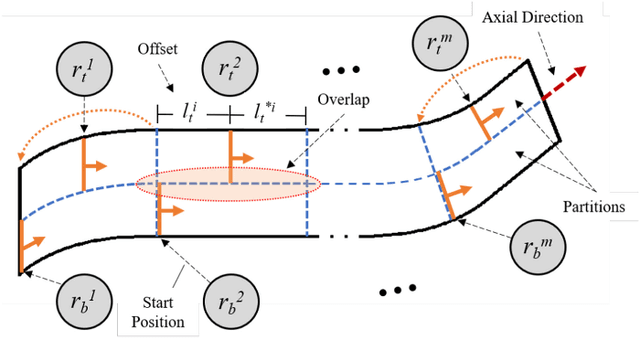

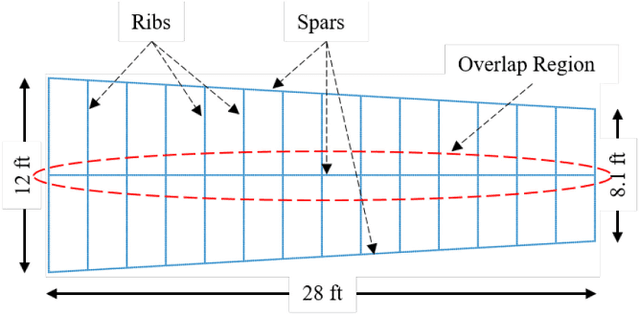

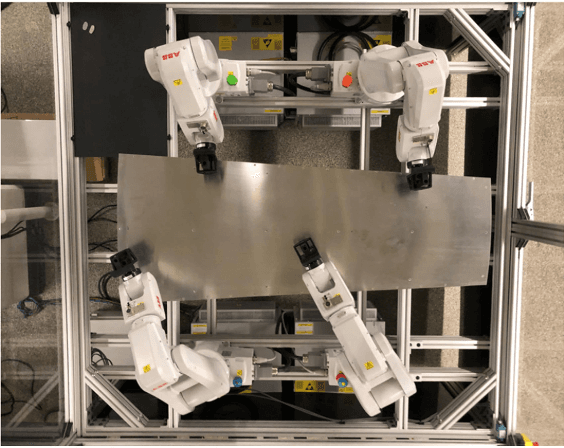

Abstract:Efficient utilization of cooperating robots in the assembly of aircraft structures relies on balancing the workload of the robots and ensuring collision-free scheduling. We cast this problem as that of allocating a large number of repetitive assembly tasks, such as drilling holes and installing fasteners, among multiple robots. Such task allocation is often formulated as a Traveling Salesman Problem (TSP), which is NP-hard, implying that computing an exactly optimal solution is computationally prohibitive for real-world applications. The problem complexity is further exacerbated by intermittent robot failures necessitating real-time task reallocation. In this letter, we present an efficient method that exploits workpart geometry and problem structure to initially generate balanced and conflict-free robot schedules under nominal conditions. Subsequently, we deal with the failures by allowing the robots to first complete their nominal schedules and then employing a market-based optimizer to allocate the leftover tasks. Results show an improvement of 13% in schedule efficiencies as compared to a greedy multi-agent scheduler on a four robot system, which is especially promising for aircraft assembly processes that take many hours to complete. Moreover, the computation times are similar and small, typically less than one second.

Add to Chrome

Add to Chrome Add to Firefox

Add to Firefox Add to Edge

Add to Edge