Morteza Daneshmand

Industry 4.0 and Prospects of Circular Economy: A Survey of Robotic Assembly and Disassembly

Jun 14, 2021

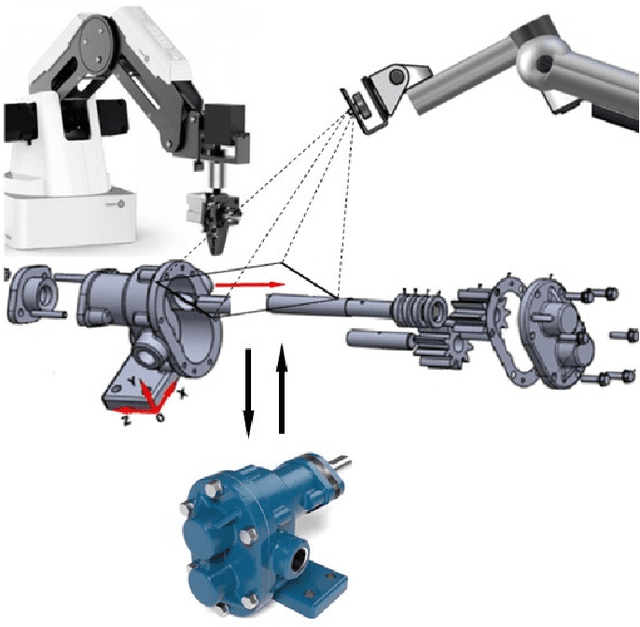

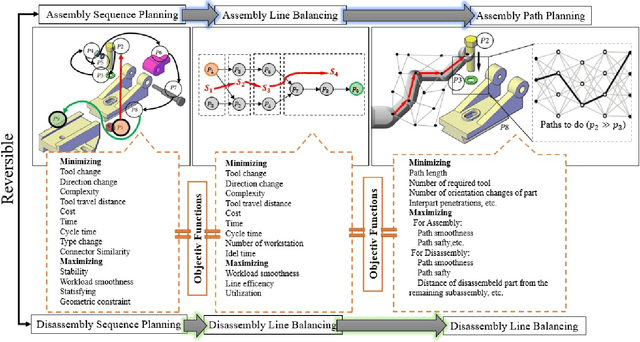

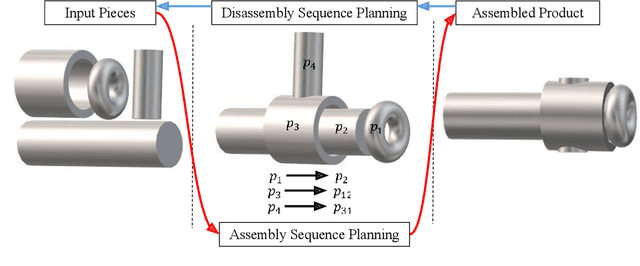

Abstract:Despite their contributions to the financial efficiency and environmental sustainability of industrial processes, robotic assembly and disassembly have been understudied in the existing literature. This is in contradiction to their importance in realizing the Fourth Industrial Revolution. More specifically, although most of the literature has extensively discussed how to optimally assemble or disassemble given products, the role of other factors has been overlooked. For example, the types of robots involved in implementing the sequence plans, which should ideally be taken into account throughout the whole chain consisting of design, assembly, disassembly and reassembly. Isolating the foregoing operations from the rest of the components of the relevant ecosystems may lead to erroneous inferences toward both the necessity and efficiency of the underlying procedures. In this paper we try to alleviate these shortcomings by comprehensively investigating the state-of-the-art in robotic assembly and disassembly. We consider and review various aspects of manufacturing and remanufacturing frameworks while particularly focusing on their desirability for supporting a circular economy.

3D Scanning: A Comprehensive Survey

Jan 24, 2018

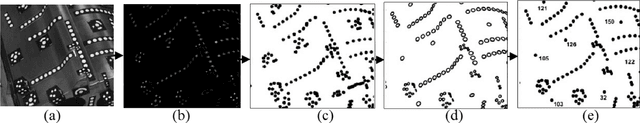

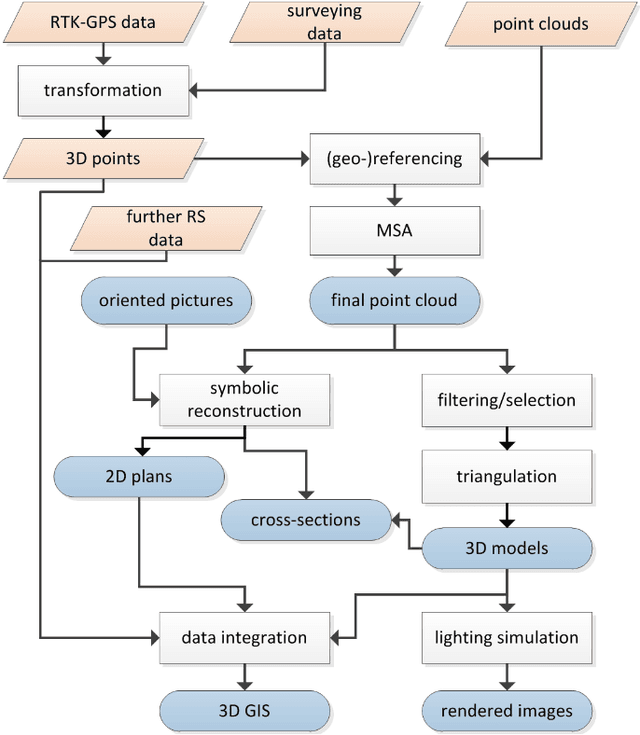

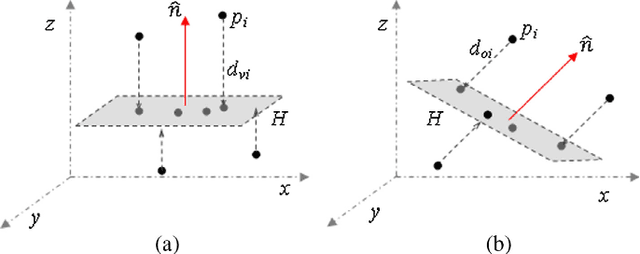

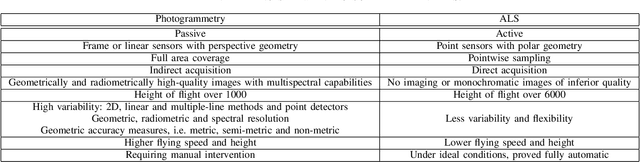

Abstract:This paper provides an overview of 3D scanning methodologies and technologies proposed in the existing scientific and industrial literature. Throughout the paper, various types of the related techniques are reviewed, which consist, mainly, of close-range, aerial, structure-from-motion and terrestrial photogrammetry, and mobile, terrestrial and airborne laser scanning, as well as time-of-flight, structured-light and phase-comparison methods, along with comparative and combinational studies, the latter being intended to help make a clearer distinction on the relevance and reliability of the possible choices. Moreover, outlier detection and surface fitting procedures are discussed concisely, which are necessary post-processing stages.

Add to Chrome

Add to Chrome Add to Firefox

Add to Firefox Add to Edge

Add to Edge